49Bend-Tech Dragon A400

Maintenance & Troubleshooting

Sensors

12

12

Sensors

Sensor Overview

The Dragon A400 uses rugged, long-lasting proximity sensors to determine critical machine

positions. Issues related to machine positioning are rarely sensor-related. Typically an issue is

the result of a sensor falling out of adjustment or a cable.

Diagnosing Sensor Issues

machine Axis experiences a collision.

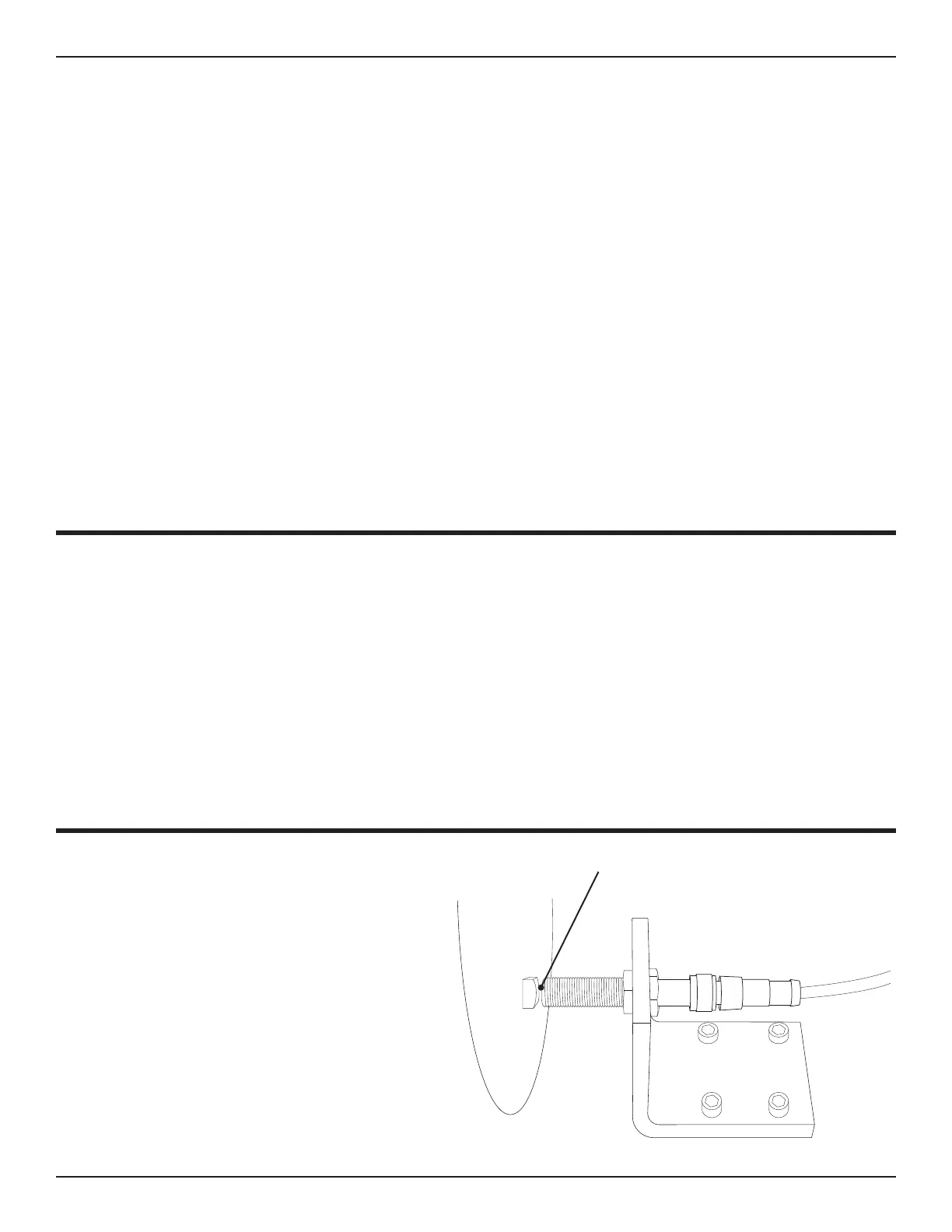

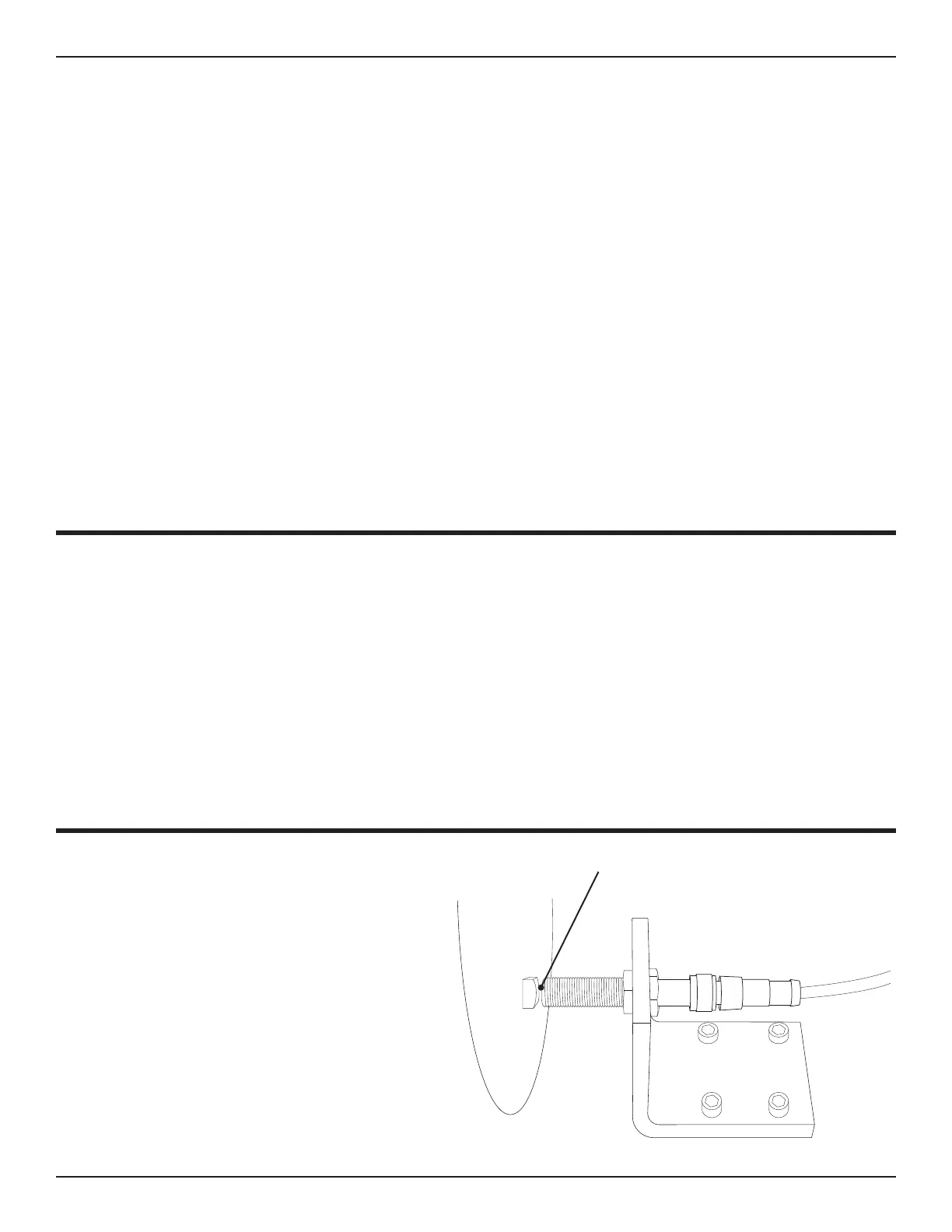

Setting a Sensor

1. Disconnect the sensor cable.

2. Position the sensor bolt directly in

front of the sensor. This will require

jogging the machine.

3. Use a feeler gauge to check the

gap between the face of the sensor

and the bolt head - the gap should

the Sensor and the Bolt

Loading...

Loading...