23Bend-Tech Dragon A400

Plasma Cutting Guide

Engraver

05

05

Engraver

Engraver Guide

The Engraver is mounted in the center of the Toolhead. When the Engraver is engaged, an

air cylinder is pressurized and the tool is pushed down to meet the material. The pressurized

cylinder allows the engraver to ride over contours in the material without damaging the tool.

Setting Engraver Air Pressure

The Engraver is driven by pressurized air. It uses two separate regulators located just behind

the Toolhead. The right side regulator controls the Engraver and is pre-set at the Bend-Tech

manufacturing facility to 70-80 PSI. The Left side regulator controls the Engraver air cylinder

and is pre-set at the Bend-Tech manufacturing facility to 7-8 PSI.

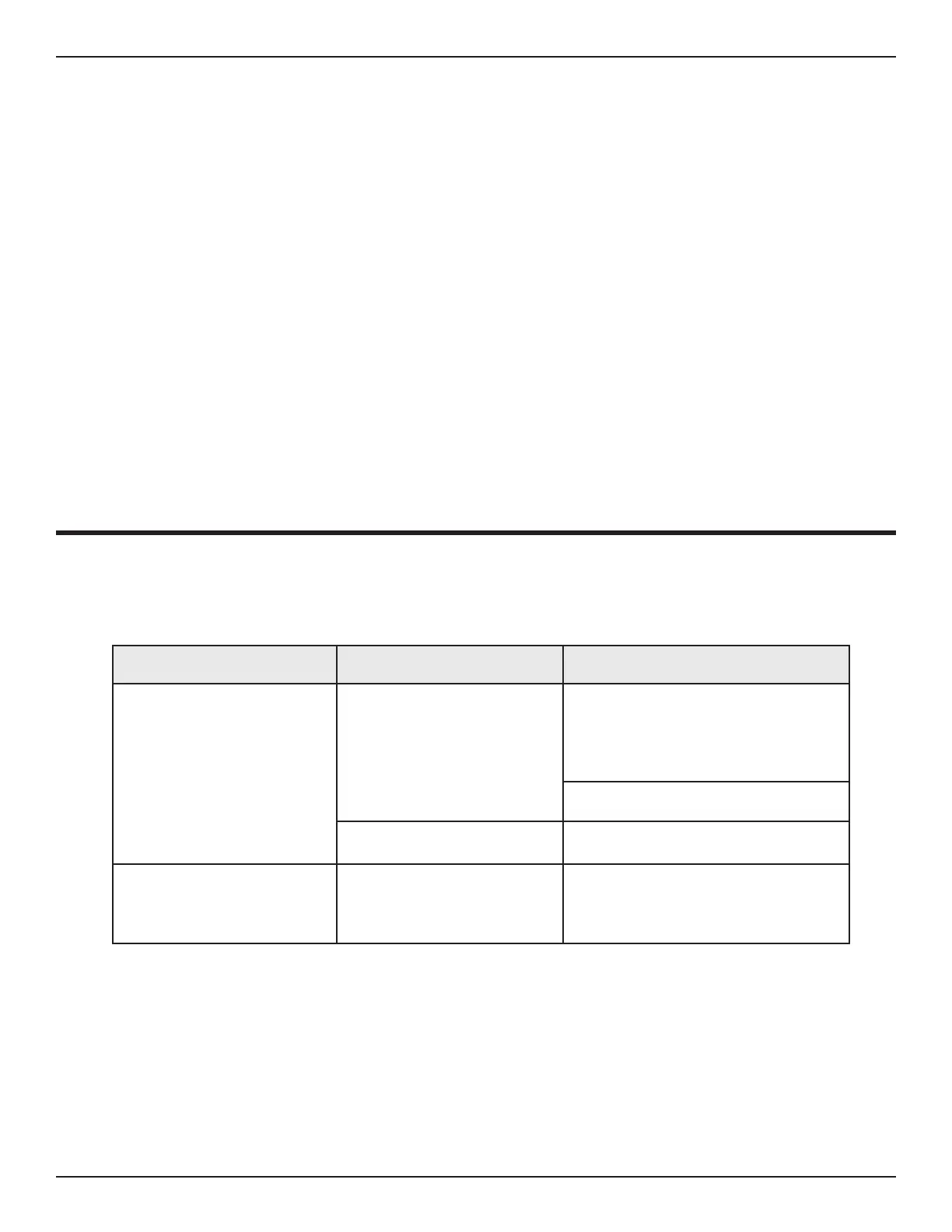

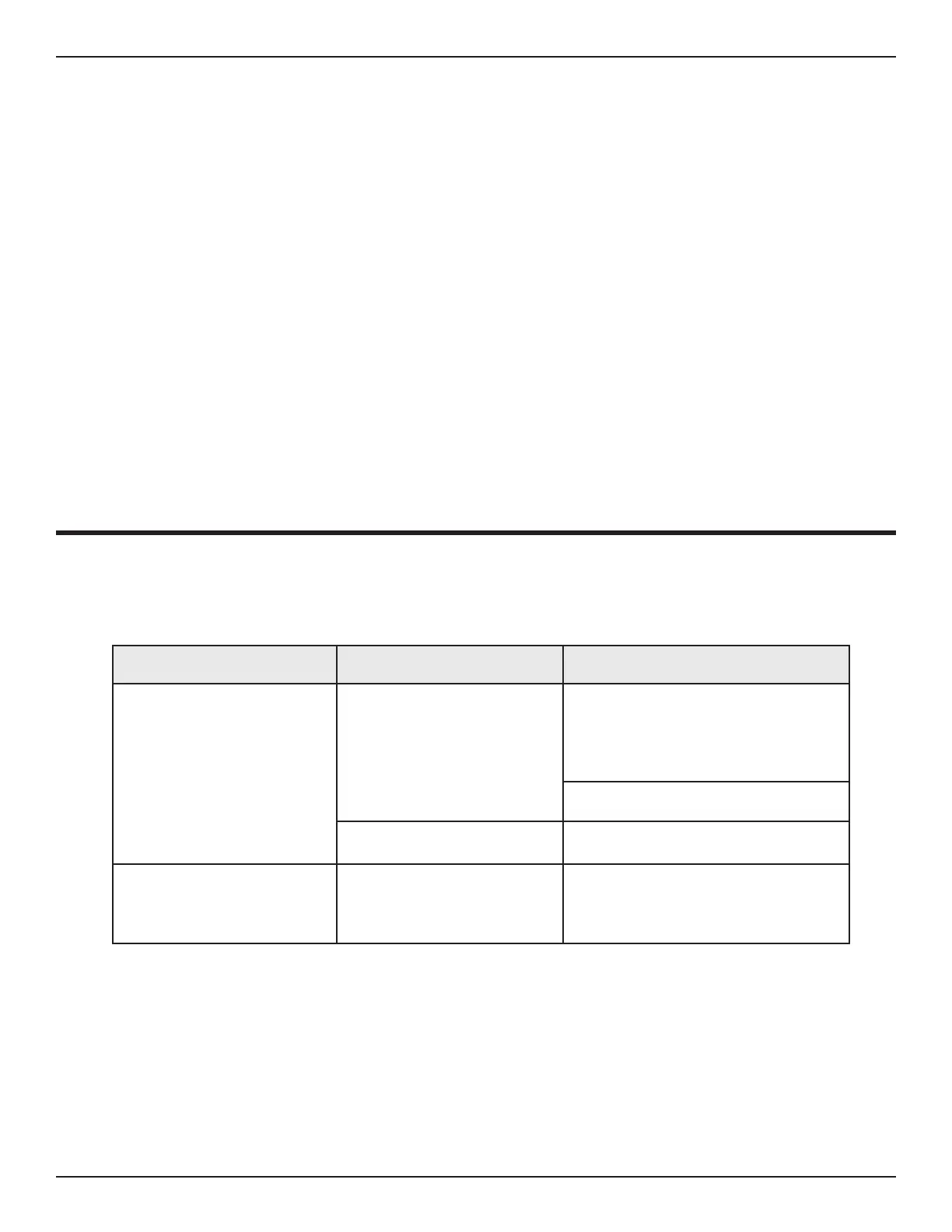

Symptom Cause Corrective Action

Engraver digging into

material or marking too

light

Engraving Height set

incorrectly

In Tube Library > Machine interface

> Tool Heights change the Engraving

Height value in the text box. It is

recommended the Operator change the

value by small increments.

Perform Engraver calibration process.

Air pressure incorrect

Set air pressure for Engraver cylinder

to 7-8 psi

Engraver not turning on

No air supply

Check air lines to engraver and main

air supply to machine. Ensure valve

on the engraver is open. Ensure bleed

valve is open.

Loading...

Loading...