21Bend-Tech Dragon A400

Maintenance & Troubleshooting

Torch

04

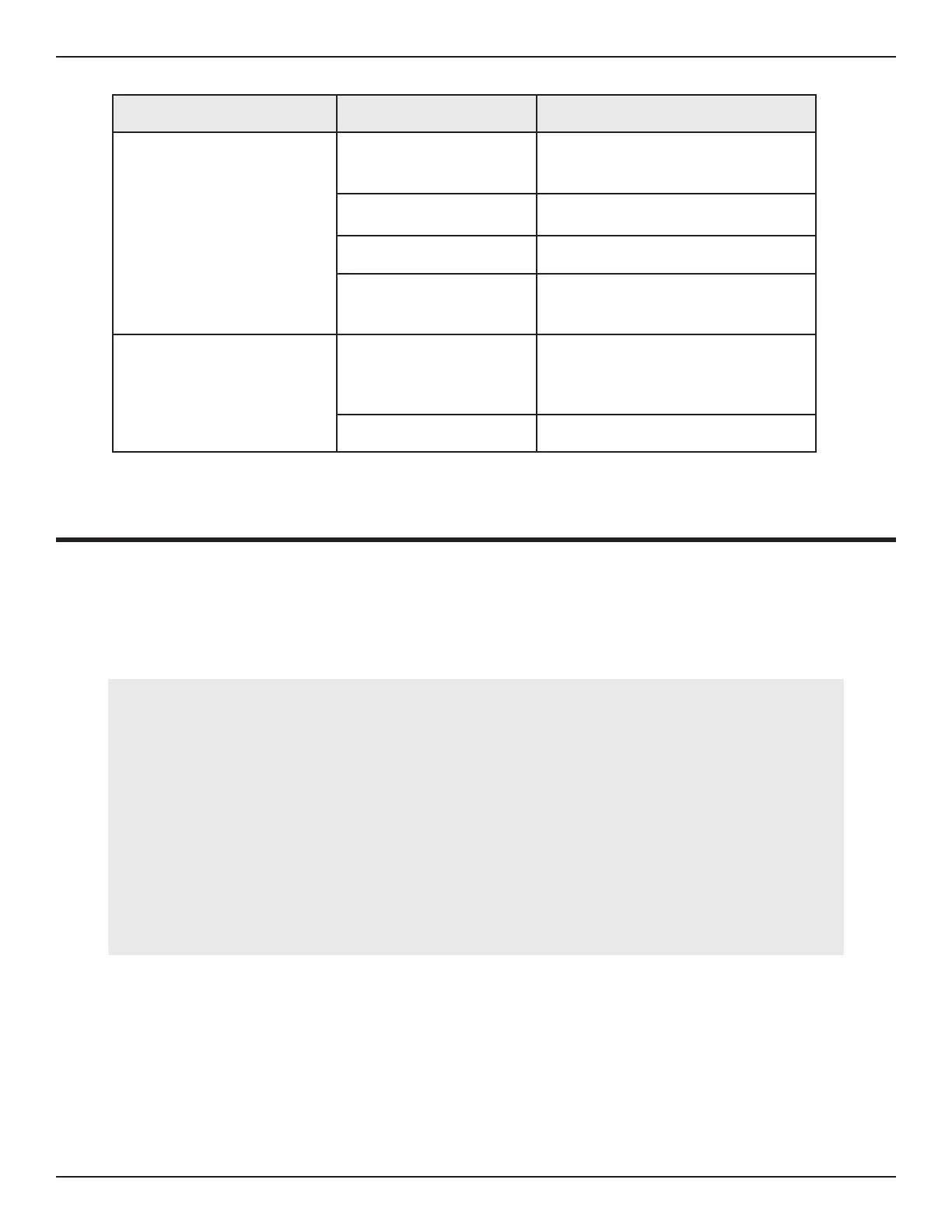

Symptom Cause Corrective Action

Torch Not Firing

Hypertherm not powered

on.

Check Hypertherm power switch;

check power cable; check cable to

Control Box.

Torch set too high.

Check Torch height with feeler gauge;

perform Torch Mount procedure.

Improper air supply. Check air supply, check air pressure.

Consumables.

Remove and inspect Torch

consumables. Refer to Consumables

Guide.

Torch Colliding With

Material

Material selected in

software does not match

material loaded into

machine.

Check to ensure material chosen in

software matches material loaded in

the machine.

Torch improperly set. Perform Torch Mount procedure.

Grounding The Torch

It is critical the Dragon A400 Torch is grounded properly. Improper grounding can lead to

numerous cutting issues. Early Dragon A400 Machines used a pair of brushes contacting the

Chuck Spindle to ground the Torch. The Operator can achieve more consistent grounding by

converting to a grounding tab mounted on the pillow block bearing.

1.

red E-stop button. Reach inside the Chuck Housing and hold the E-Stop button while

unscrewing the chrome retaining collar. Remove the chrome retaining collar and yellow

E-stop label. Remove the E-Stop button and lay out of the way on the Trolley. Remove the

Chuck Housing, leaving the Front Plate.

2. Use a ¾ in. socket to remove the rear pillow block mount bolt nearest the Y motor.

Tools Needed

•

• Ratchet

• 12 in. extension

•

• ¾ in. socket

• ½ in. wrench

• Grinder

Loading...

Loading...