FunctionFunction

CC612(4G)_D00325_04_M_XXEN/03.2019

9

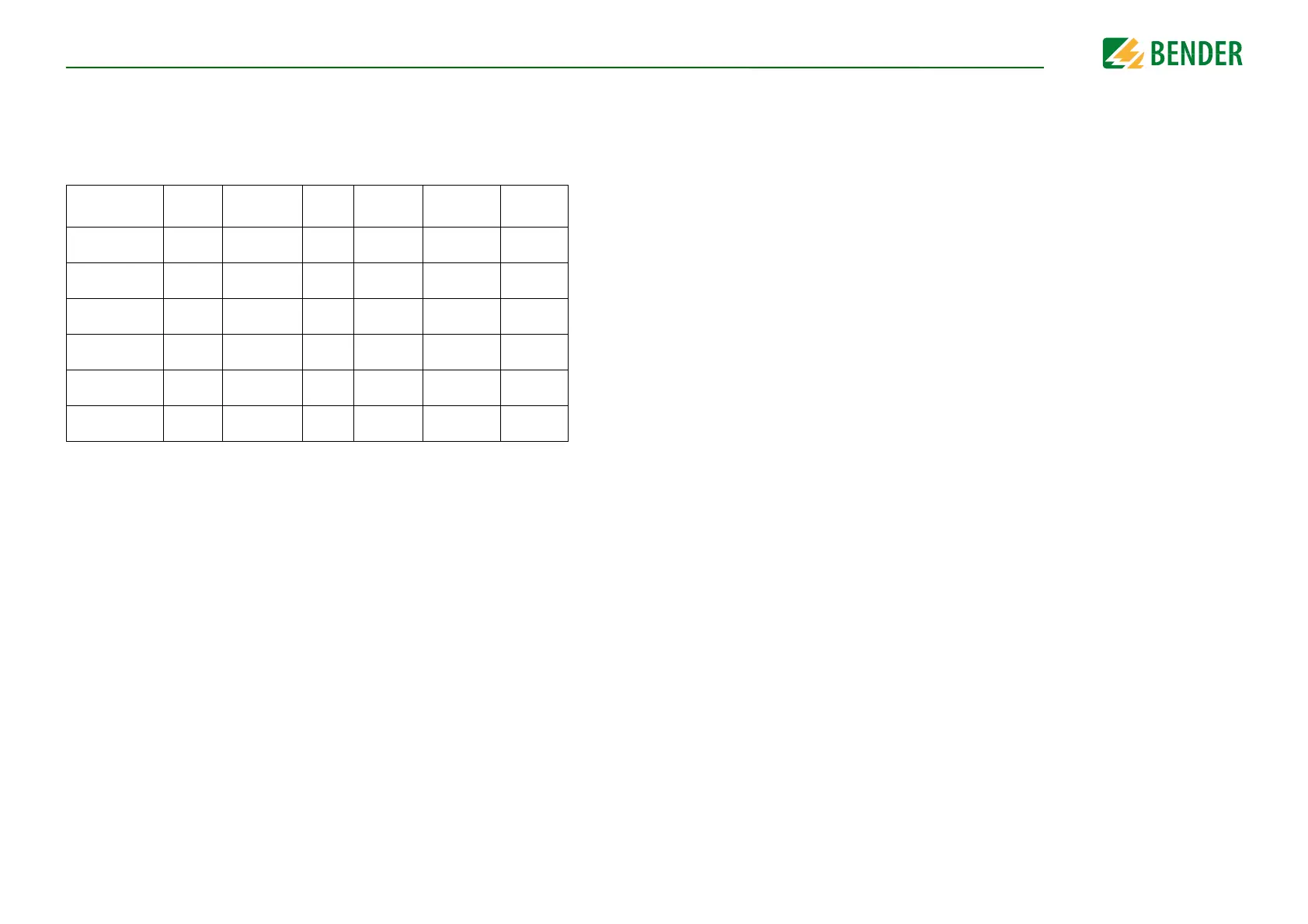

3.2.1 Product variant overview

Several product variants are available and the table below gives an overview of these variants.

Some connect to a digital eHZ meter using an optical interface while others read Modbus me-

ters. In general, variants can read meters with an S0 interface. Ordering details can be found

on Page 44

.

* Optional and enabled by a software update

Type Modem Meter

RDC-

MD*

PLC*

hardware

LEDs

User

interface

CC612 -1M4PR 4G

eHZ and S0

interface

Ready,

Alarm, PLC

CC612 -2M4PR 4G

Modbus, S0

interface

Ready,

Alarm, PLC

CC612 -1S0PR ---

eHZ and S0

interface

Ready,

Alarm, PLC

CC612 -2S0PR ---

Modbus, S0

interface

Ready,

Alarm, PLC

CC612 -2M4R 4G

Modbus, S0

interface

---

Ready,

Alarm

CC612 -2S0R ---

Modbus, S0

interface

---

Ready,

Alarm

3.3 Functional description

As well as the charge controller, a charging system also consists of a type A RCD, a relay

contactor, which is directly connected to a type 1 or type 2 socket, or to an attached cable

with a type 1 or type 2 plug. These essential components are shown in Chapter 3.3.2.

3.3.1 General functions

• A charging system may also consist of a meter, and if the meter should be read digi-

tally, either a smart digital meter (EMH eHZ) or a digital Modbus meter is required.

• The charge controller reads the digital eHZ meter readings using a standard opti-

cal reader attached to the charge controller via an RJ10 plug.

• If the Modbus version is used, the Modbus wires are attached directly to the

charge controller.

• Alternatively, any meter with an S0 interface can be attached to one of the availa-

ble inputs.

• A 12 V power supply is needed to operate the charge controller and an RFID module

can be used to facilitate simple user interaction. The RFID module is a separate PCB

and is connected to the charge controller using a standard RJ45 cable.

• Power flow toward the vehicle is controlled by the contactor (using a signal voltage

of up to 30 V), which is itself controlled by the the charge controller via a relay in the

charge controller.

• The SIM card slot (available on charge controller Master variants only) is positioned

on the charge controller front panel. The SIM card can have a PIN number which can

be configured via an internal configuration web interface. The APN settings for the

card can also be configured via an internal configuration web interface.

• Also positioned on the front panel are two USB interfaces:

• The first known as CONFIG is used to configure the charge controller. Optionally,

this interface can also be used to apply software updates.

• The other USB interface allows the connection of peripheral USB devices.

• Both USB interfaces are used to enable a Master/Slave connection. Master/Slave

operation is configured by connecting the USB configuration interface (CONFIG)

of the data gateway with 4G modem to the Ethernet/USB WLAN interface of the

data gateway without 4G modem using a USB cable. Refer to Page 17 for further

information.

• Only the front panel of data gateways with 4G modem variants features a connec-

tion for a 4G antenna.

Loading...

Loading...