Take down the number of the pipe to be bent, find and

remove it from the deck. Remember to place a marker of

some type in its place. The cards are filed in numerical

sequence by the number shown on the top left section of

the card. Only the last four digits shown are in sequential

order. Some cards start with a prefix such as T3 or T5 then

are followed by a four digit number. ALWAYS disregard the

prefix and follow the last four digits only.

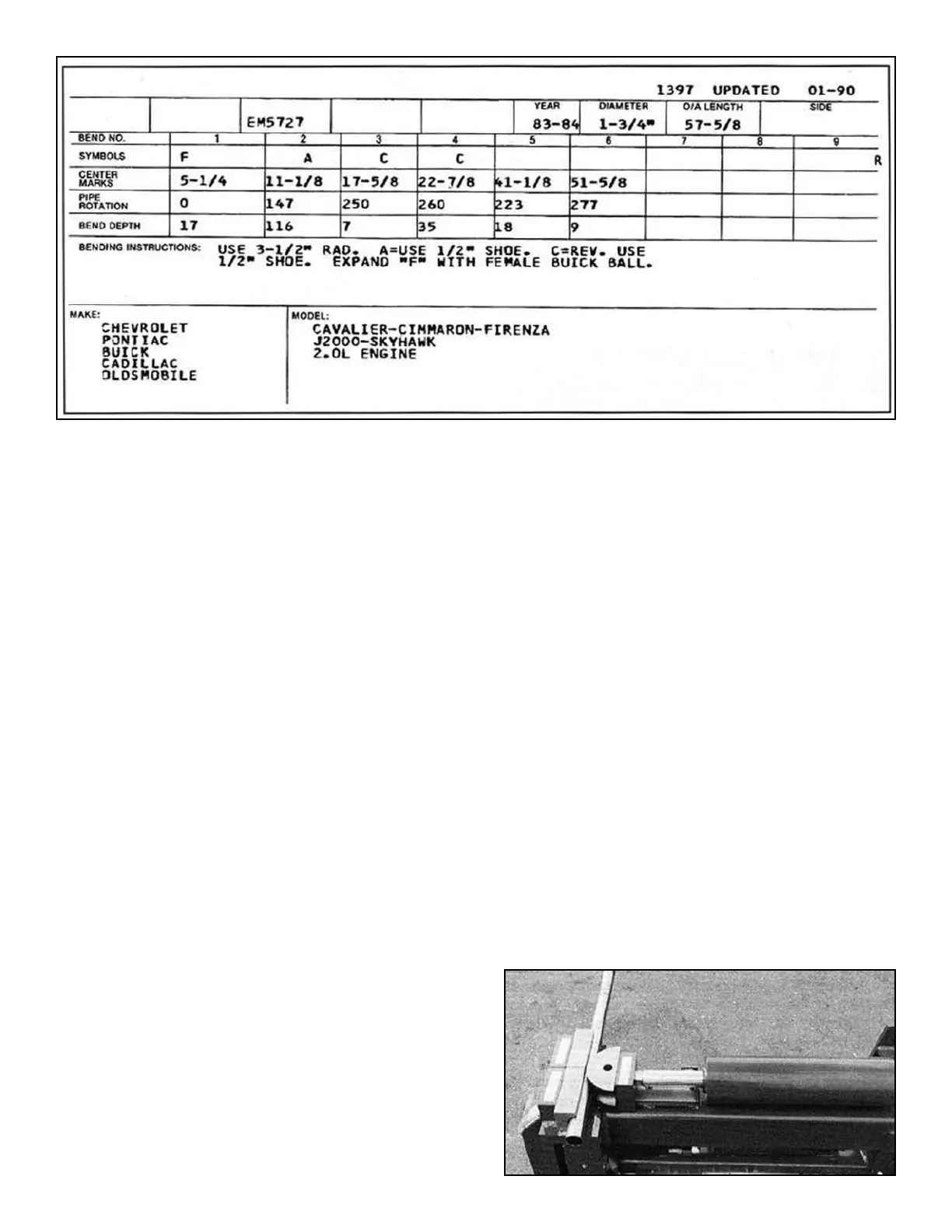

DEFINITION OF CARD

SECTIONS:

YEAR - Gives the year of the vehicle that the card pertains

to.

DIAMETER - The original equipment factory recommend-

ed tubing diameter for that particular vehicle,

O/A LENGTH - Overall length of tubing required for that

particular pipe. Also referred to as the cut-off point.

SIDE - When more than one section of tubing is required

for a particular card number, this section shows if it is the

front, rear, left or right side.

SYMBOLS - Shows certain symbols that pertain to indi-

vidual bending instructions that are explained in greater

detail in the BENDING INSTRUCTIONS section. The

symbol section also includes the descriptive “F” and “R”

symbols that indicate how the pipe fits on the vehicle. “F”

means front and “R” means rear.

CENTER MARKS - Refers to the actual locations or mea-

surements that the bends will be located.

PIPE ROTATION - Shows in degrees what the correct

pipe rotation (or plane) is for each bend.

BEND DEPTH - Shows in degrees what the correct bend

depth is for each bend.

MAKE - Gives the make of the vehicle. Chevrolet, Pontiac,

Ford, Chrysler, etc.MODEL - Gives descriptive factors

such as the model, engine and frame size.

BENDING INSTRUCTIONS - Shows what radius die will

be used in addition to other tooling such as half shoes

and three quarter shoes. Also gives instructions on

reversing and certain end-fInishing requirements. Not all

applications will be shown on the card.

Follow these step-by-step instructions to bend the pipe

for the card shown above.

1. Select the proper tubing size for the application as

called for in the DIAMETER SECTION of the card.

(See Recommended Tubing Chart on page 48) Wipe

tubing to remove excess oil.

2. Install the correct radius die as called for in the

BENDING INSTRUCTION section. Two back shoes

are required unless otherwise specifIed. Place tubing

in the bender between the back shoes and radius die

with the greater portion of the tubing extending out

the LEFT side of the bender. This is necessary so

that you can mark the tubing with the appropriate

CENTER MARKS shown on the card.

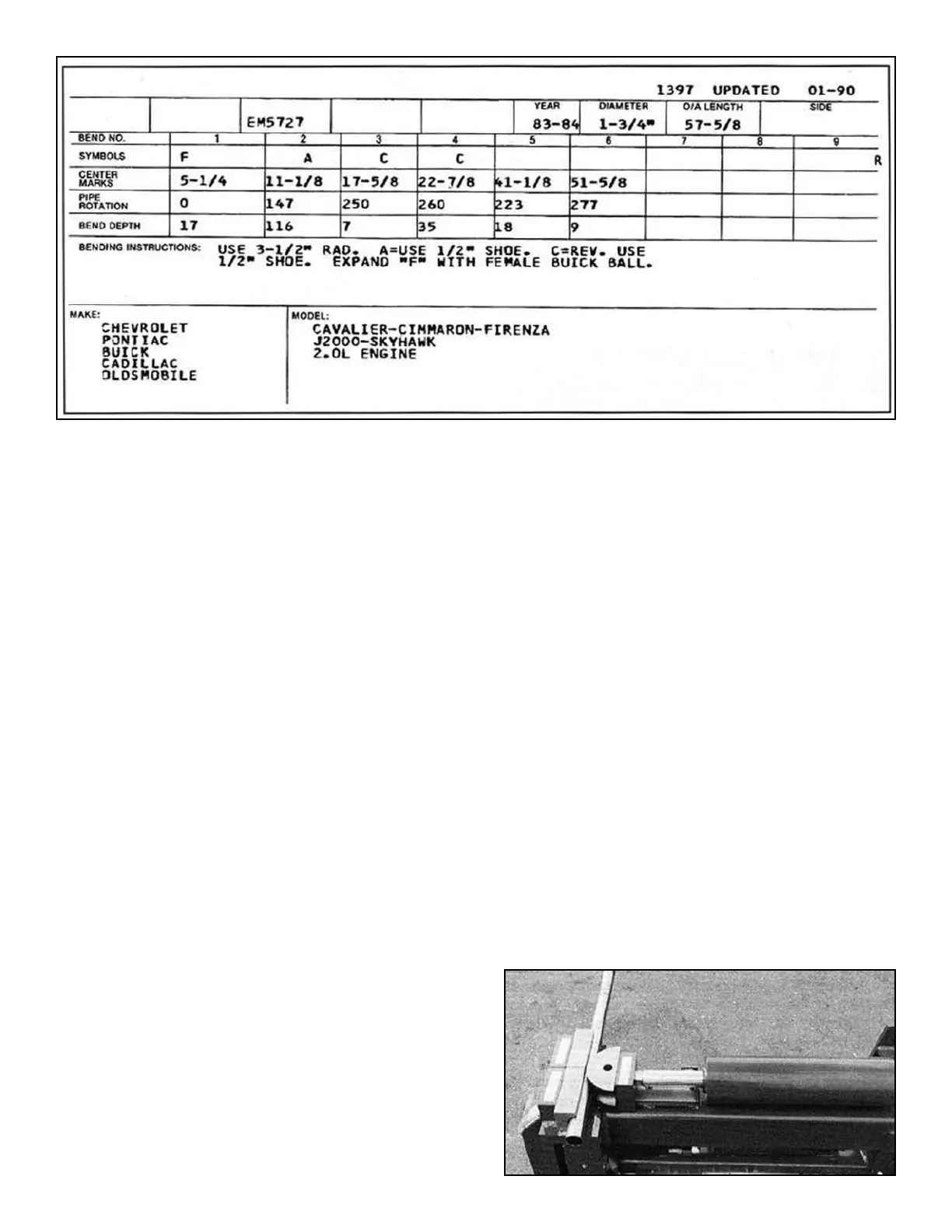

3. Engage the bending dies until the pusher

block springs are compressed and the tubing is held

fIrmly. Carefully control the advancement of the

radi us die so as not to dent or bend the tubing at this

time. (See figure 1-A)

16 Bender Operation Manual

Sample card layout to be used in conjunction with bending instructions.

Figure 1-A

Loading...

Loading...