19 Bender Operation Manual

22. Review the SYMBOLS section of the card and

check for any special instructions.

23. On bend number four you will notice that a

REVERSE USE HALF SHOE is again called for.

Keep the ROTATION DIAL on the LEFT side for this bend.

24. Advance the radius die forward until the pusher block

springs are compressed and the tubing is held securely.

25. Rotate the tubing so that the pendulum pointer or

dial indicator points to 260 degrees.

26. Advance the radius die to 35 degrees then retract

the die to the original starting position.

27. Review the SYMBOLS section of the card and check

for any special instructions for bend number five.

28. On bend number five no special instructions are

shown. In this case, return the ROTATION DIAL to

the right side and install the full BACK SHOE. A

HALF SHOE is not required for this bend.(See figure 3-B.)

29. Advance the radius die forward until the pusher block

springs are compressed and the tubing is held securely.

30. Rotate the tubing so that the pendulum pointer or

dial indicator points to 223 degrees.

31. Advance the radius die to 18 degrees then retract

the die to the original starting position.

32. Review the SYMBOLS section of the card and check

for any special instructions for bend number six.

33. On bend number six no special instructions are shown.

34. Advance the radius die forward until the pusher block

springs are compressed and the tubing is held securely.

35. Rotate the tubing so that the pendulum pointer or

dial indicator points to 277 degrees.

36. Advance the radius die to 9 degrees then retract the

die to the original starting position.

37.You are now finished bending the pipe. Remove the

ROTATION DIAL and cut the tubing end off at the

last O/A mark. (See figure 3-C.)

38. Now check the BENDING INSTRUCTIONS section

and check for any END FINISHING requirements.

On this particular card, it calls for a FEMALE BUICK

BALL on the FRONT or “F” side of the pipe. See

page 12 for TYPICAL END FINISHING illustrations.)

PATTERN BENDING

To pattern bend, proceed as follows. In order to retain the

information for later use, save the information as described

below.

NOTE:

Use the blank program card found on the next page

as a master to make additional

copies for later use.

1. Select the proper tubing size and die set to do the

job. Try to match the radius size with that of the existing

pipe.

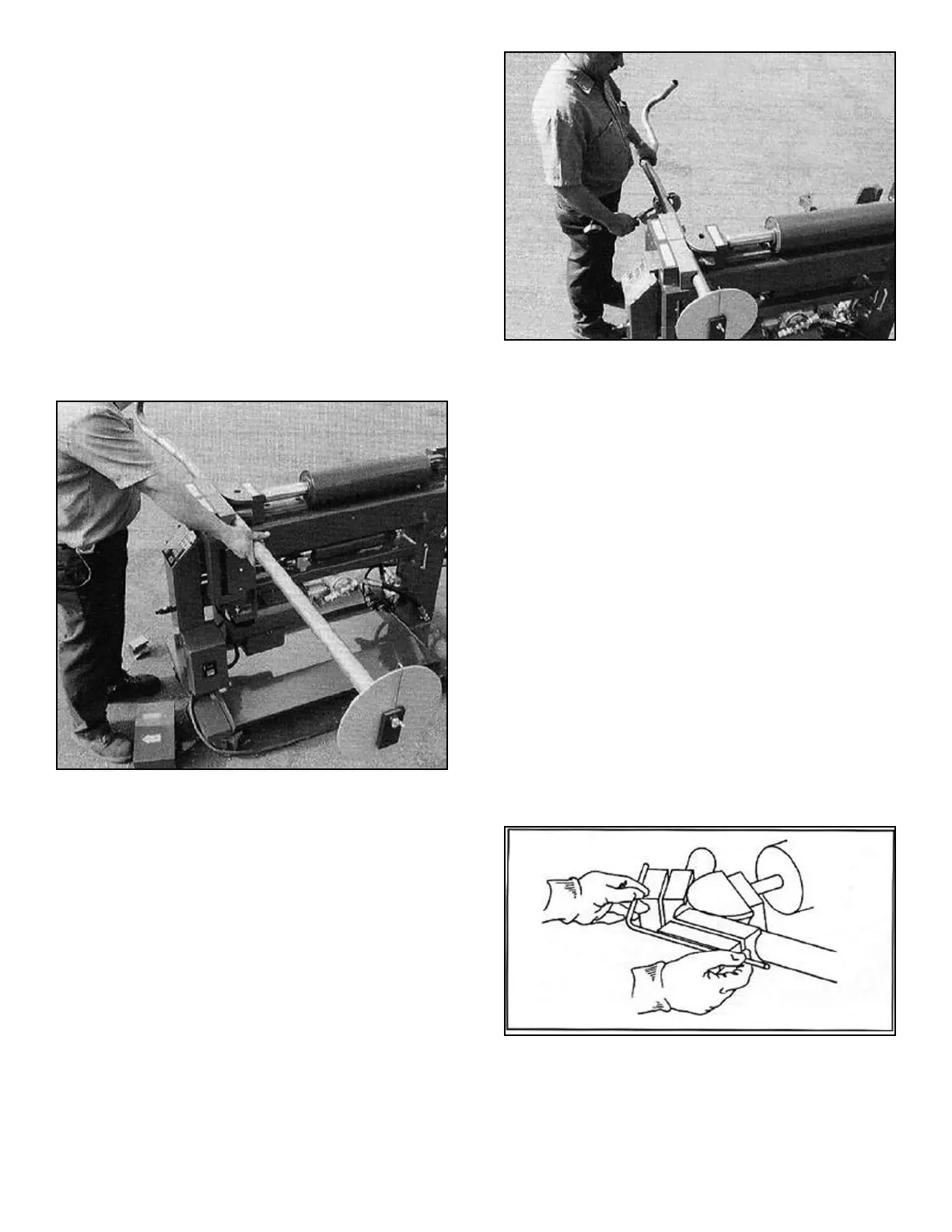

2. Place the tubing in the bender with the greater portion

of the tubing protruding out the right side of the

bender.

3. Place the master pattern (existing pipe or bent wire

on the top of the back shoes so that the first bend is

centered between the back shoes.

4. Adjust the tubing out the left side of the bender so

that the tubing end matches the length with that of

the master. (See figure 1-A) Secure the straight pipe

by advancing the radius die until the pusher block

springs compress.

Bender Operation Manual 19

Figure 3-B

Wire pattern being used as a master.

Figure 3-C

Loading...

Loading...