27 Bender Operation Manual

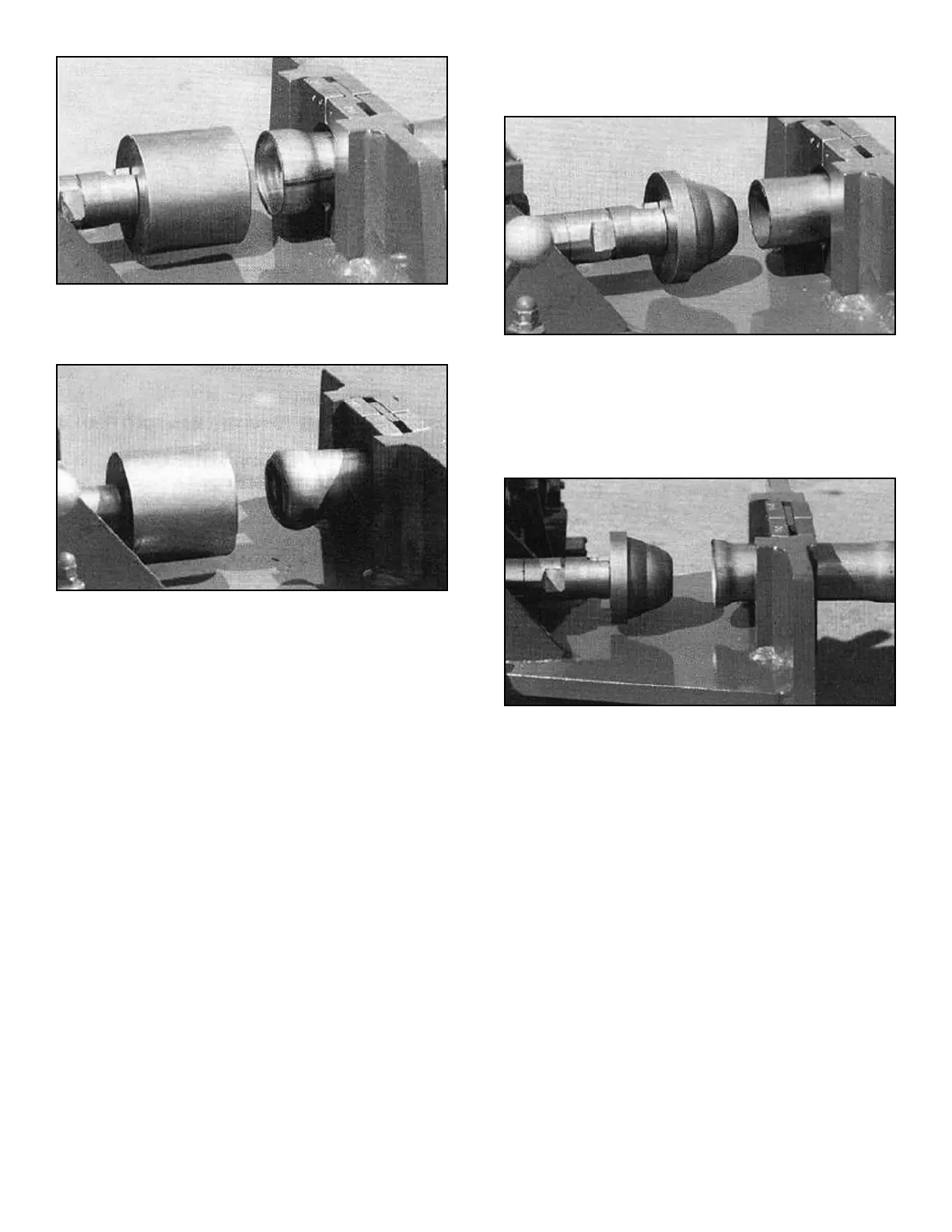

11. Slowly move the tool forward until the desired ball is

achieved. This procedure requires careful control.

(See figure 1-B)

12. Retract the die by lifting up on the control handle.

13. Separate the collar from the tubing. Remove tooling

and return to the storage area.

USING THE BFED TOOLS TO MAKE FEMALE

BALL EXPANSIONS

IMPORTANT NOTE:

When making male ball expansions it is

necessary to first install the pipe flange or clamp

around the tube prior to finishing the ends.

The BFED-134/214 & BFED-200/212 are forming tools

for flaring pipe ends to make female ball expansions.

Each tool is “stepped” and has the ability to flare two dif-

ferent sizes. The BFED-134/212 is used for tubing sizes

1-3/4” and 2-1/2” while the BFED-134/214 is used for

tubing sizes 1-3/4” and 2-1/4”.

Follow these steps to produce female ball expansions

using the BFED dies. See chart on page 12 for typical

end finishing illustrations.

1. Retract the swager cylinder completely by lifting the

valve handle up.

2. Install the required BFED for the appropriate tubing

size on the ST-1 adapter attached to the end of the

cylinder shaft.

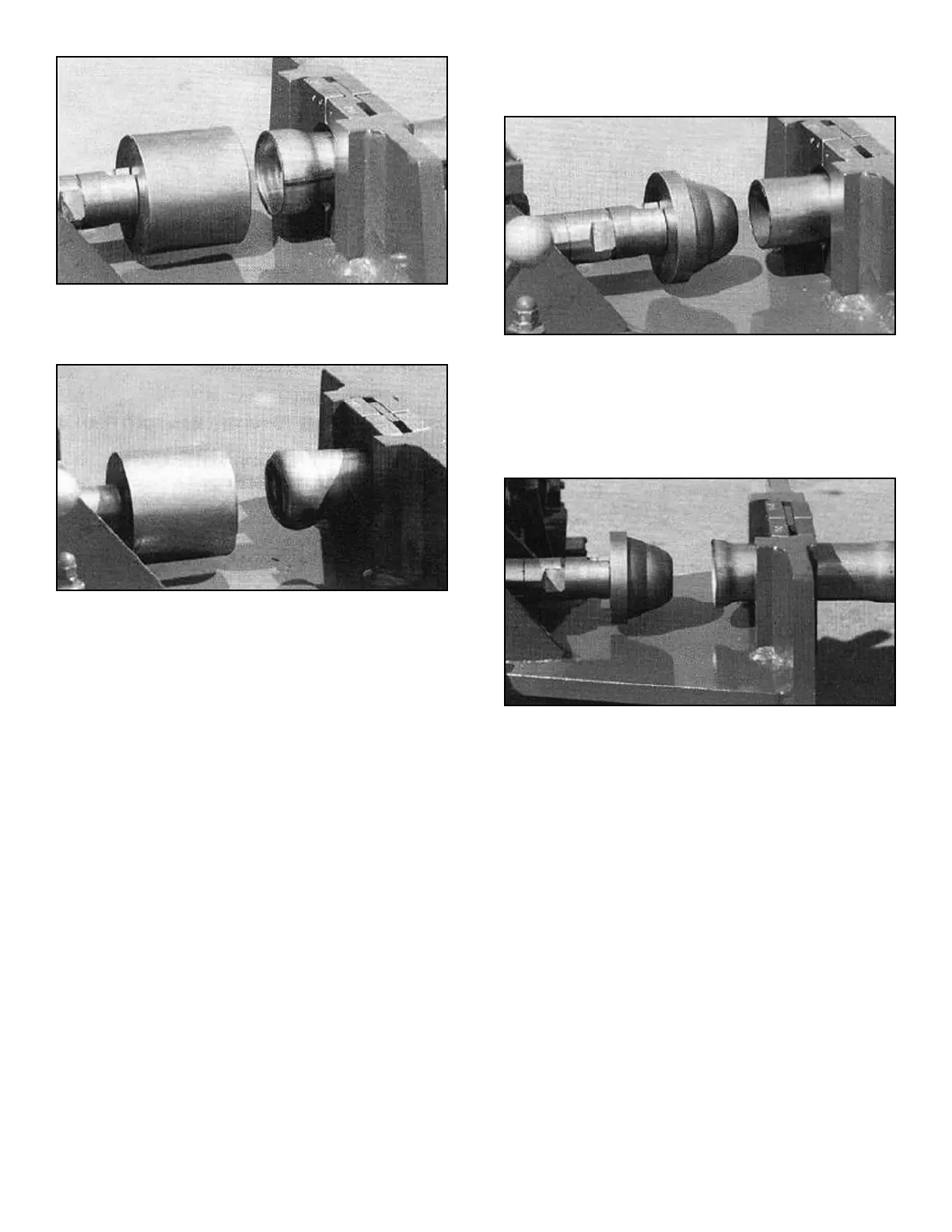

3. Install the required HAC adapter collar around the

tubing and position within the swager clamp blocks.

4. Leave at least three inches of tubing extended

beyond the inside edge of the adapter collar.

(See figure 2-B)

5. Snug the collar back into the clamp blocks by gently

pushing back on the collar assembly.

6. Slowly, while depressing the valve handle down,

move the shaft forward until the tool enters the

tubing. Be sure that the tool is centered with the

tubing. Continue moving the cylinder forward

until the expansion is formed. (See figure 3-B)

7. After the tubing has been expanded, retract the die

by lifting up on the control handle. Separate the collar

from the tubing. Remove tooling and return to the

storage area.

USING THE HPF-300 TOOL TO MAKE

45 DEGREE FLARES AND FLAT FLARES

IMPORTANT NOTE:

When making 45 degree flares and flat flares it is

necessary to first install the pipe flange or clamp

around the tube prior to finishing the ends.

Follow these steps to produce flares using the HPF-300

tool. See chart on page 12 for typical end finishing illustra-

tions.

1. Retract the swager cylinder completely by lifting the

valve handle up.

2. Install the HPF-300 tool on the ST-1 adapter attached

to the end of the cylinder shaft.

3. Install the required HAC adapter collar around the

tubing and position within the swager clamp blocks.

Bender Operation Manual 27

Figure 3-A

Figure 1-B

Figure 2-B

Figure 3-B

Loading...

Loading...