If the return pressure needs adjusting, proceed as follows.

1. Turn the machine on.

2. Place a radius die and set of back shoes in

position. Tubing will not be required for this

operation.

3. Advance the radius die until it just comes in contact

with the back shoes.

4. Using the manual controls, initiate the retract

sequence and read the pressure shown on the

gauge located to the front of the machine.

5. If an adjustment is required, loosen the locking nut

that secures the adjusting screw.

6. To increase the pressure, turn the adjusting screw

slightly clockwise; to decrease, counter-clockwise.

Never exceed 350 P.S.I.

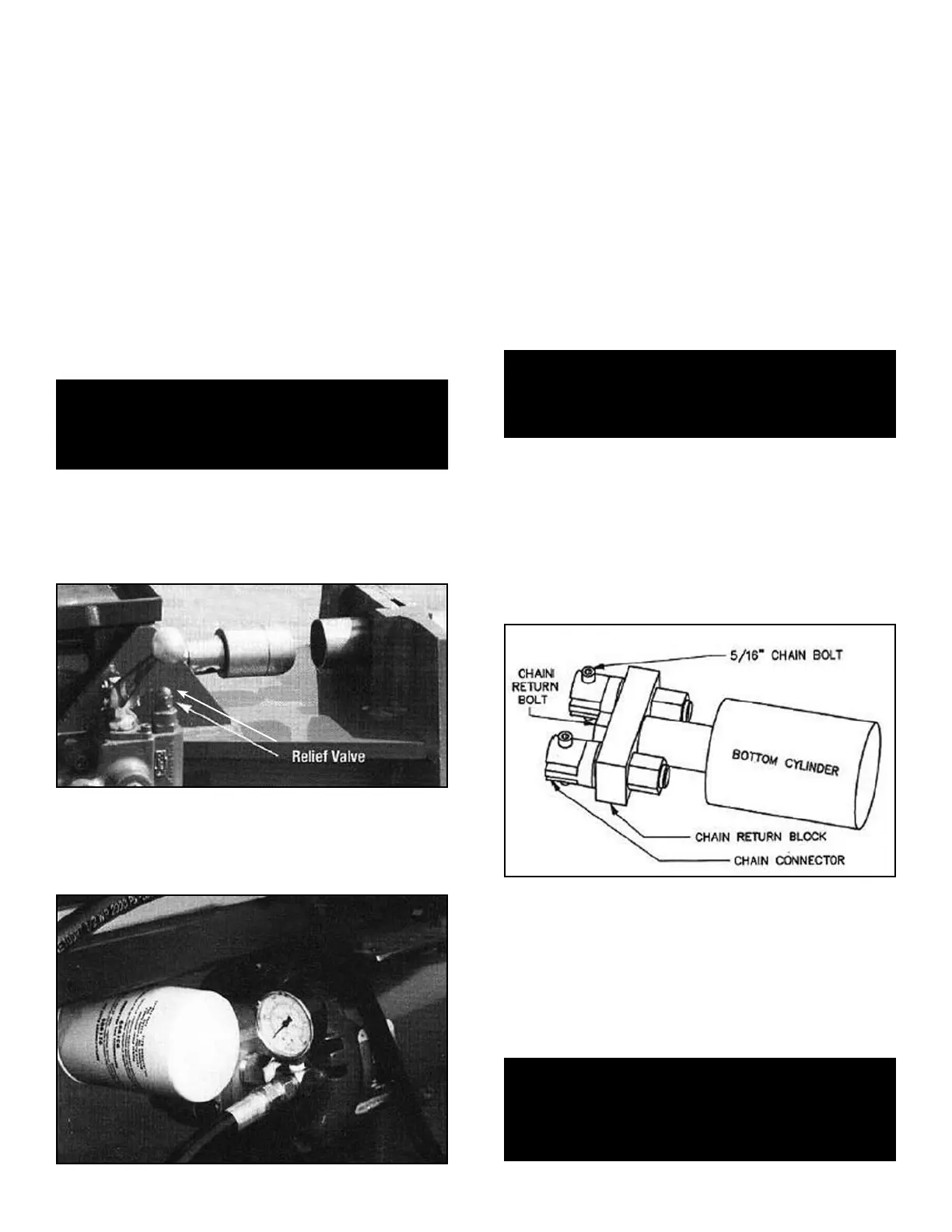

SYSTEM PRESSURE - Your bender has a built in relief

valve in order to control maximum pressure output for the

entire machine. As the fluid exits the hydraulic pump, it first

enters the swager control valve that contains an adjustable

“ball-check” relief valve. (See figure 3-A)

The normal operating system pressure should be set

at 3200 P.S.l. This pressure is read on the gauge located

near the center of the machine next to the hydraulic pump.

(See figure 3-B)

To check and adjust the system pressure, proceed as follows.

1. Turn the machine on.

2. Press the swager control valve down until the swager

cylinder is bottomed out.

3. When the cylinder bottoms out or is extended to

maximum travel the pressure will surge and the

machine will “groan” as the relief valve opens up and

fluid is redirected back to the reservoir. This is when

the reading should be taken.

4. If an adjustment is required, loosen the locking nut

that secures the adjusting screw on the relief valve.

5. To increase the pressure, turn the adjusting screw

slightly clockwise; to decrease, counter-clockwise.

Never exceed 3200 P.S.I.

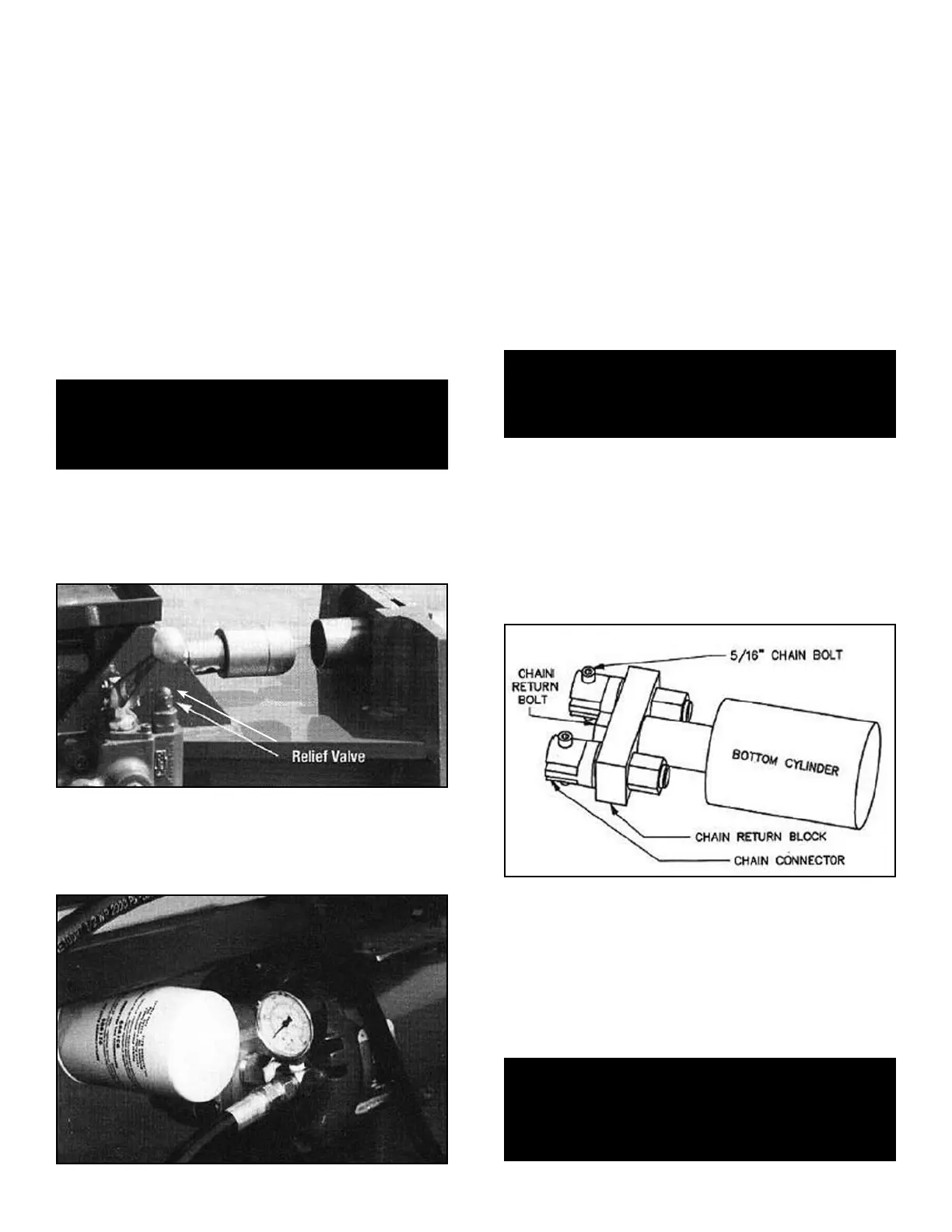

ADJUSTING THE CHAINS - When the chains are prop-

erly adjusted, the threaded chain connector will protrude

from the adjusting nut approximately one quarter of an

inch. Both chains should have equal tension. If one chain

has more slack than the other, tighten the chain connec-

tor adjusting nut using a 1-1/16” open end wrench.

NEVER tighten the chain connector so that it is bottomed

out against the chain return block. (See figure 3-C)

NOTE:

The chain return bolt has the tendency to loosen

during normal use. If it is necessary to tighten this bolt,

remove one of the chain connectors and tighten

using a 1-3/8” open end wrench.

After the bolt is secure, replace the chain

connector and adjust as described above.

34 Bender Operation Manual

CAUTION!

Never exceed 350 P.S.I. for the return pressure unless

specifically instructed to do so by the factory for

special circumstances.

CAUTION!

Never exceed 3200 P.S.I. for the system pressure

unless specifically instructed to do so by the factory

for special circumstances.

CAUTION!

If any part of the chain or assembly bolts appear to be

damaged in any way, discontinue use until

they are replaced.

Figure 3-A

Figure 3-B

Figure 3-C

Loading...

Loading...