9. Lift the valve handle up until the arbor extends and

the segment set is released.

10. Check the finished expansion end by placing it over

the end of tubing of the corresponding size. The

expansion should allow the tubing to fit snugly.

11. The expansion can be made to fit looser by turning

the buttress canister counter-clockwise or tighter by

turning the buttress canister clockwise.

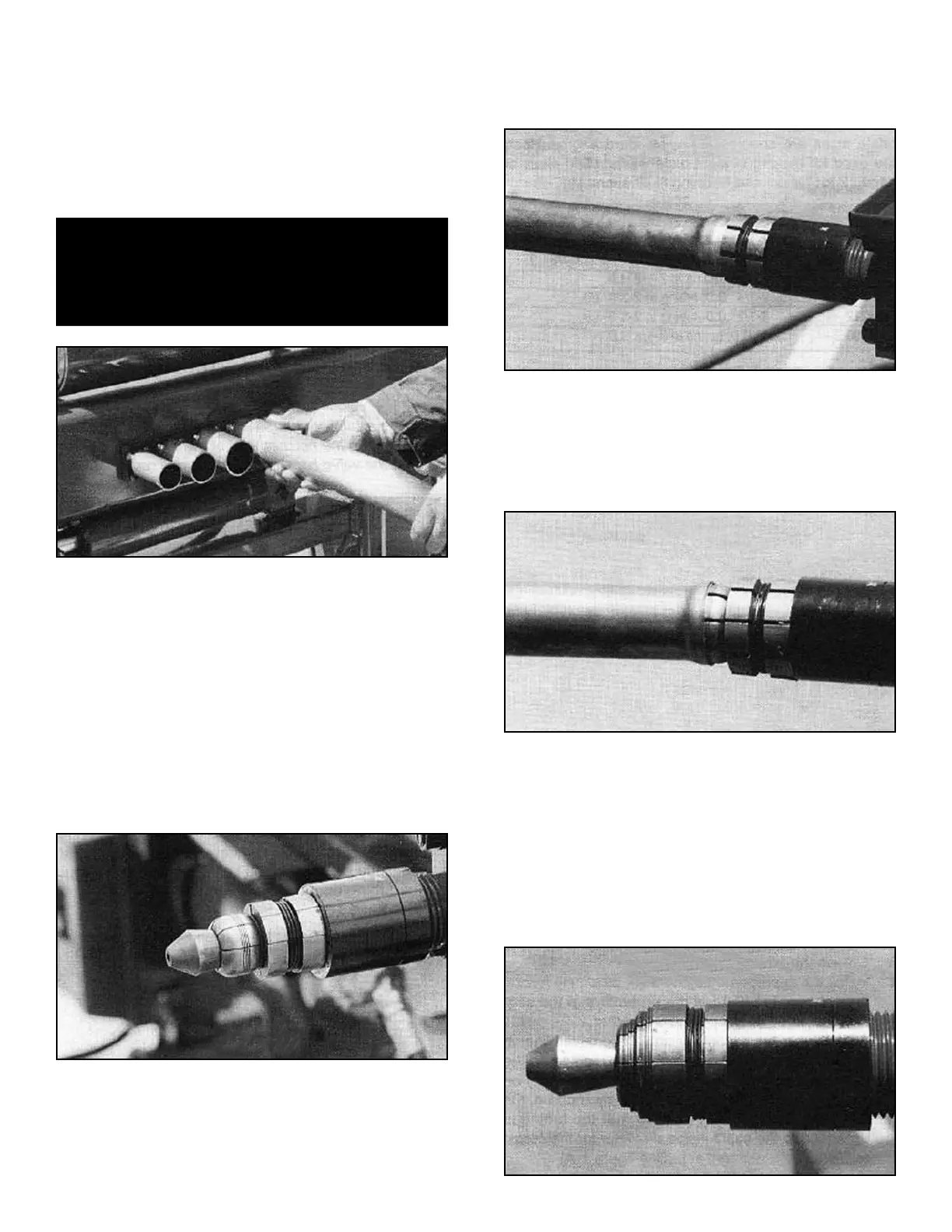

USING THE BALLJOlNT SEGMENT SETS - Ball-joint

segment sets are used to make ball-joint expansions

on shorter tubing ends. They are available in three sizes;

2”, 2-1/4” and 2-1/2”. These are not included in standard

tooling packages. (See chart on page 12 for typical end

finishing illustrations.)

Ball-type expansions can be made quick and easily using

ball segment sets on the internal expander as explained

below.

1. Slide the proper size ball-joint segment set over the

arbor. (See figure 1-A)

2. Place the tubing over the ball segment set until the

tubing end is flush with the shoulder.

3. Adjust the buttress canister until the grooved line on

the canister is lined up with the grooved line on the

pointer.

4. Depress the valve handle to form the ball on the end

of the tubing. Be careful not to distort the end of the

tubing. (See figure 2-A)

5. To make a female ball expansion, place the tubing

over the arbor and segment set until the tubing is

positioned midway at the grooved area. Depress the

valve handle to flare the end of the tubing to match

with the mating male ball joint. (See figure 3-A)

USING THE FLARE SEGMENT SETS - These segment

sets are used to make 45 degree flares on tubing ends.

Three different sets are available that work on tubing

sizes 1-1/2” - 2-1/2”. These are not included in standard

tooling packages. (See chart on page 12 for typical end

finishing illustrations.)

To produce a flare, proceed as follows.

1. Slide the proper size flare segment set over the arbor.

(See figure 1-B)

24 Bender Operation Manual

HELPFUL TIP...

Cut off sections of tubing in all sizes approximately 3” in

length and weld them to a bracket similar to the one

shown below. Attach to your bender and use it to check

your expansions.

Figure 2-A

Figure 3-A

Figure 1-B

Figure 1-A

Loading...

Loading...