INTRODUCTION

Your new bender is a “press-style” bender that is capable

of bending, flaring and swaging tubing up to 3 inches in

diameter. The thickness of the tubing plays an important

part. (See previous chart for recommended tubing

allowances.) The front of the bender is where all the bend-

ing is performed. The top cylinder activates the bending or

radius die which moves forward through the back shoes.

The bottom cylinder keeps pressure applied to the back

shoes by a chain assembly and integrated hydraulic

sequence valve. In addition to the contoured shape of the

radius dies, resistance pressure is applied to help the tub-

ing maintain it's shape.

DEFINITION OF TERMS

The following definitions explain the major components

and operating features of your machine. The RIGHT,

LEFT, and REAR sides of the bender are relative to the

FRONT of the machine where all bending is performed.

BENDER- The whole machine including all end

finishing components.

BODY- The main 6” x 6” tubular structure that sits

horizontal to the floor and is located just below the top

cylinder.

SWAGER OR SWAGER BOX- The expanding/flaring

unit located to the rear of the bender which utilizes

pipe collars in conjunction with bullet shaped expander/

forming dies to perform a variety of tube end finishing.

INTERNAL EXPANDER- The expanding/flaring unit

located to the rear of the machine that utilizes seg-

mented expander dies. These “segment sets” are expand-

ed by the means of a tapered arbor pulled through their

center. This style of end finishing is usually required with

shorter pieces of tubing such as muffler nipples which do

not allow the use of a collar.

TOP CYLINDER- The main hydraulic bending cylinder

located at the top of the bender. It's primary function is to

activate movement of the radius dies.

BOTTOM CYLINDER- The hydraulic cylinder located

just below the body of the bender. It's primary function is

to apply resistance pressure to the back shoes as the

radius die pushes through.

RESERVOIR-The rear vertical leg that contains the

hydraulic oil.

FRONT UPRIGHT- The front vertical leg.

BENDER MODELS

There are nine different bender models available.

1000-BL 1000-BAS 1000-BA

1302-BL (Blue-Bullet) 1302-BAS 1302-BA

1502-BL 1502-BAS 1502-BA

The following is a brief description of their controls and

operating features. The model nomenclature consists of a

number (1302) followed by letters BA. The numbers des-

ignate what style frame assembly is used while the letters

signify the control features.

FRAME CONFIGURATION

1000 Series- A machine capable of bending only. Does

not come with any end finishing capabilities.

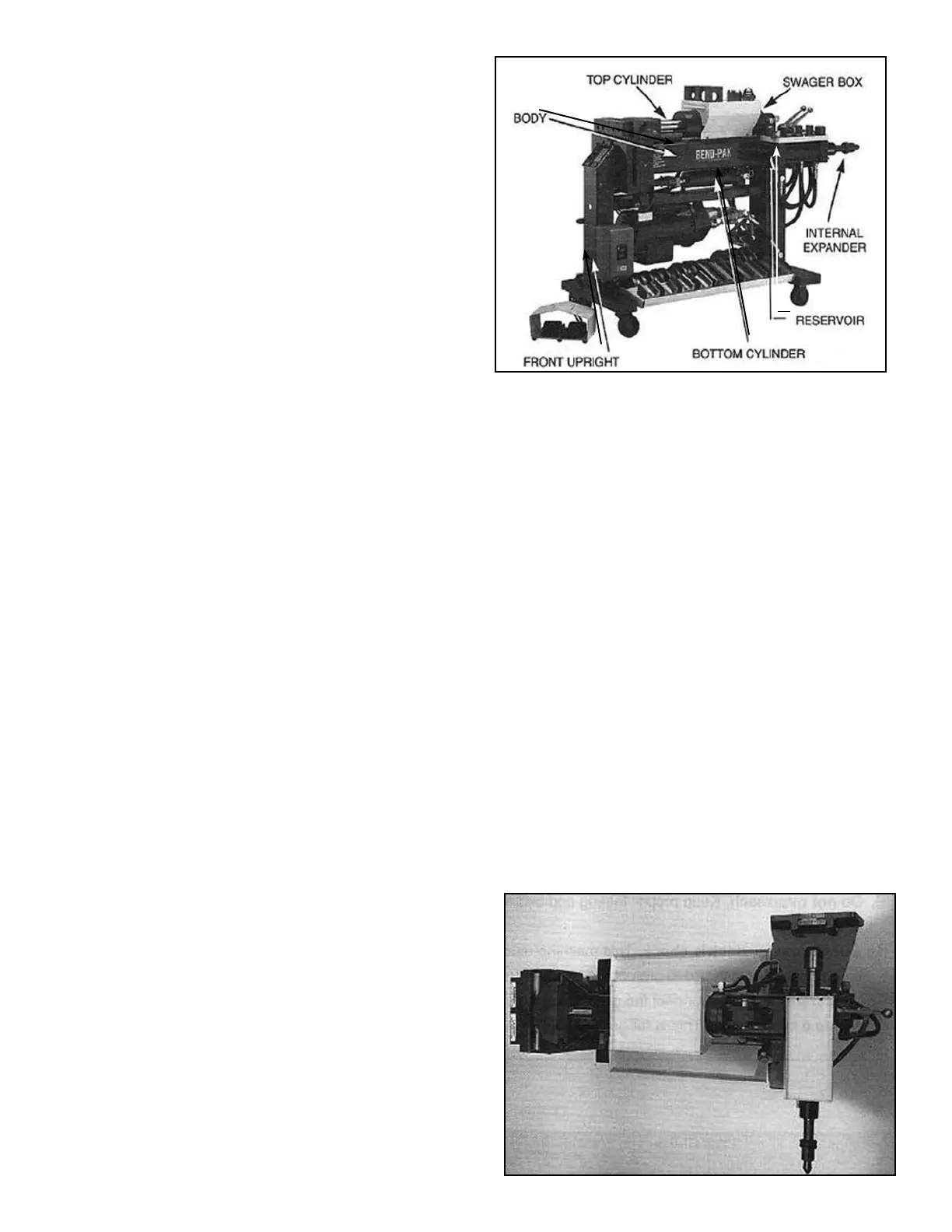

1302 Series- A machine capable of bending and end

finishing. Equipped with both swager and internal

expander. A double-ended hydraulic cylinder is used for

both end finishing functions. The end finishing assembly,

(the swager and internal expander) is positioned

“cross-wised” on the rear of the machine.

6 Bender Operation Manual

Overhead view of Model 1302

Side view of Bender showing major components.

Loading...

Loading...