6. It will not be necessary to loosen the rear most bolt `

on the guide plate for this service.

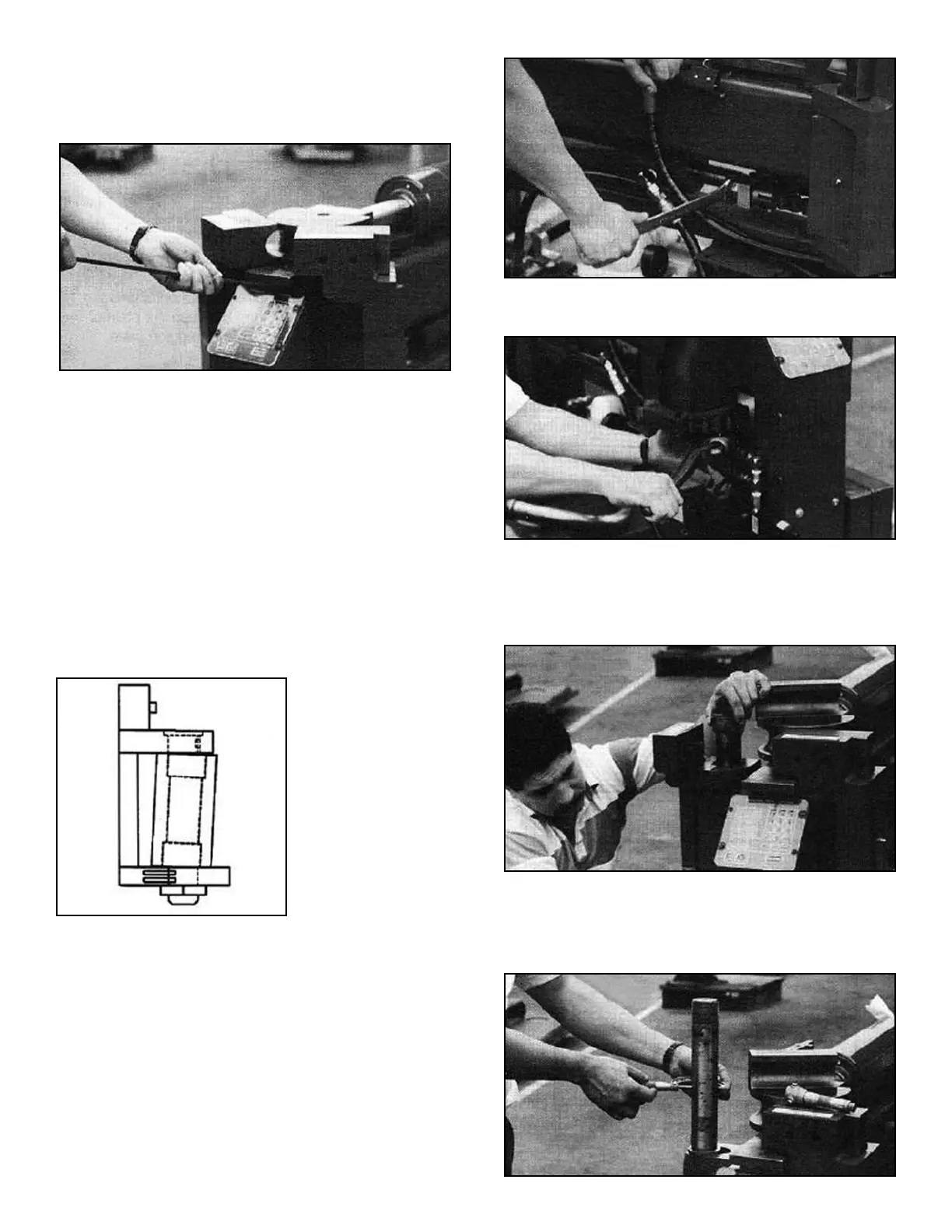

7. Using a pry bar, elevate the front of the guide plate.

(See figure 2-A)

8. Using shim stock .002 - .005 thick, shim underneath

the guide plate as required until proper levelness is

achieved.

9. Tighten all allen bolts on the guide plate then grease

well.

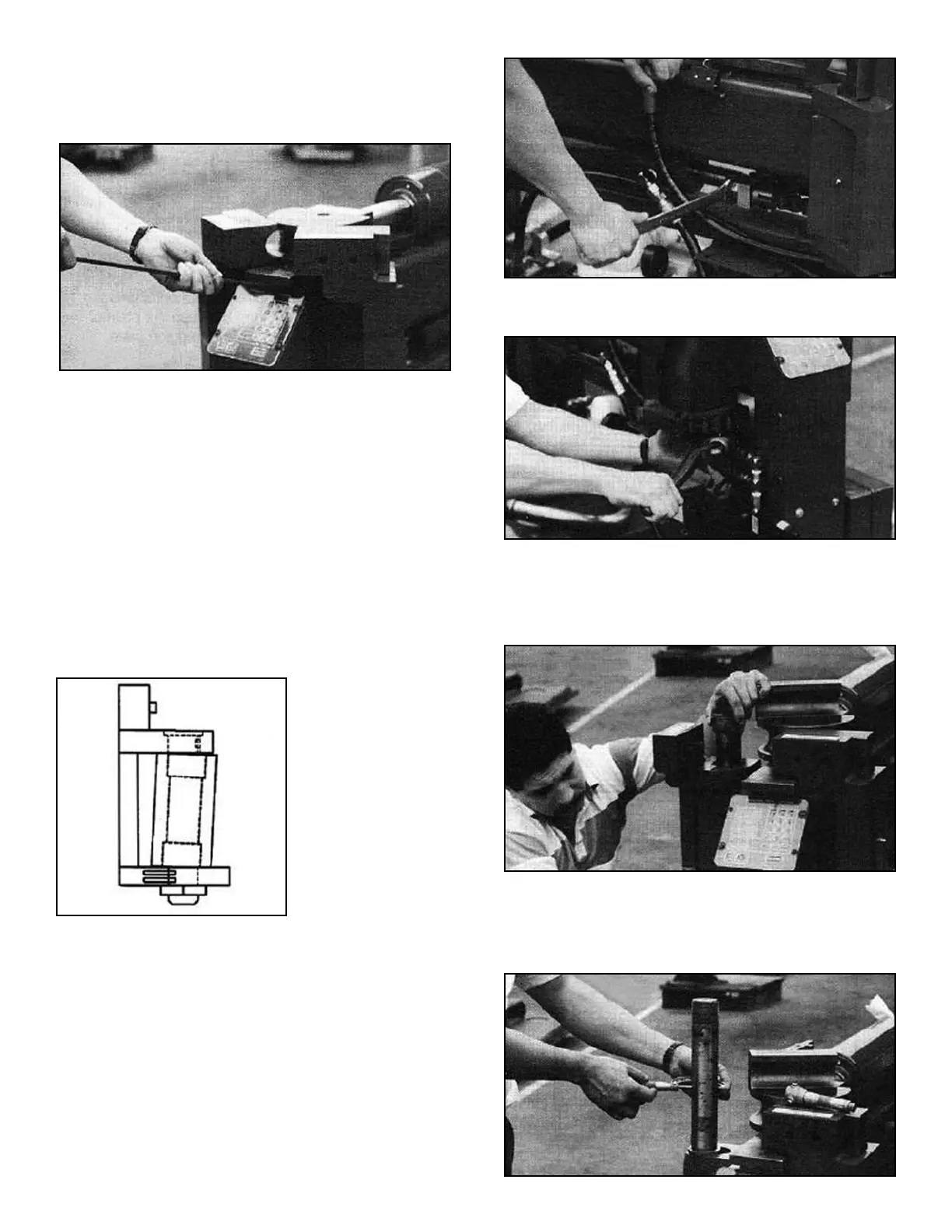

VISUALLY CHECKING THE

BARREL BUSHlNGS FOR WEAR

The barrel bushings should be checked every six months

for excessive wear. If the barrel bushings become worn,

the barrel shafts will have too much play and the gates

will become misaligned causing the tubing to wrinkle.

(See figure 2-B)

To check the barrel bushings for excessive wear it is nec-

essary to completely remove one of the gate assemblies

and visually check the bronze bushings. The left gate

assembly is the easiest to remove. If the bushings are

worn on the left side of the barrel, then the right side

bushings will be equally worn. There are two 2-1/2” x 2” x

1-1/2” bronze bushings press fitted on the top and bottom

of each side of the barrel assembly. To visually check

these bushings, follow the steps outlined below.

1. Disassemble the left side chain assembly by removing

the left side chain connector. (See figure 2-C)

2. Remove the barrel shaft nut located below the left

side gate assembly. (See figure 3-A)

3. Using a rubber mallet, carefully tap the shaft up and

out of the barrel. BE CAREFUL when removing shaft

to prevent threads from being damaged. Be sure to

keep shaft key as it is required for re-installation.

(See figure 3-B)

4. Remove the left gate assembly.

5. Clean shaft and inside of barrel of all grease and debris.

6. Visually check shaft for excessive wear. Replace

shaft if diameter is less than 1.997”. (See figure 3-C)

36 Bender Operation Manual

This diagram shows

the gate assembly

misaligned with the

barrel due to

excessive

wear on the barrel

bushings.

Figure 2-C

Figure 3-A

Figure 3-B

Figure 2-B

Figure 3-C

Figure 2-A

Loading...

Loading...