22 Bender Operation Manual

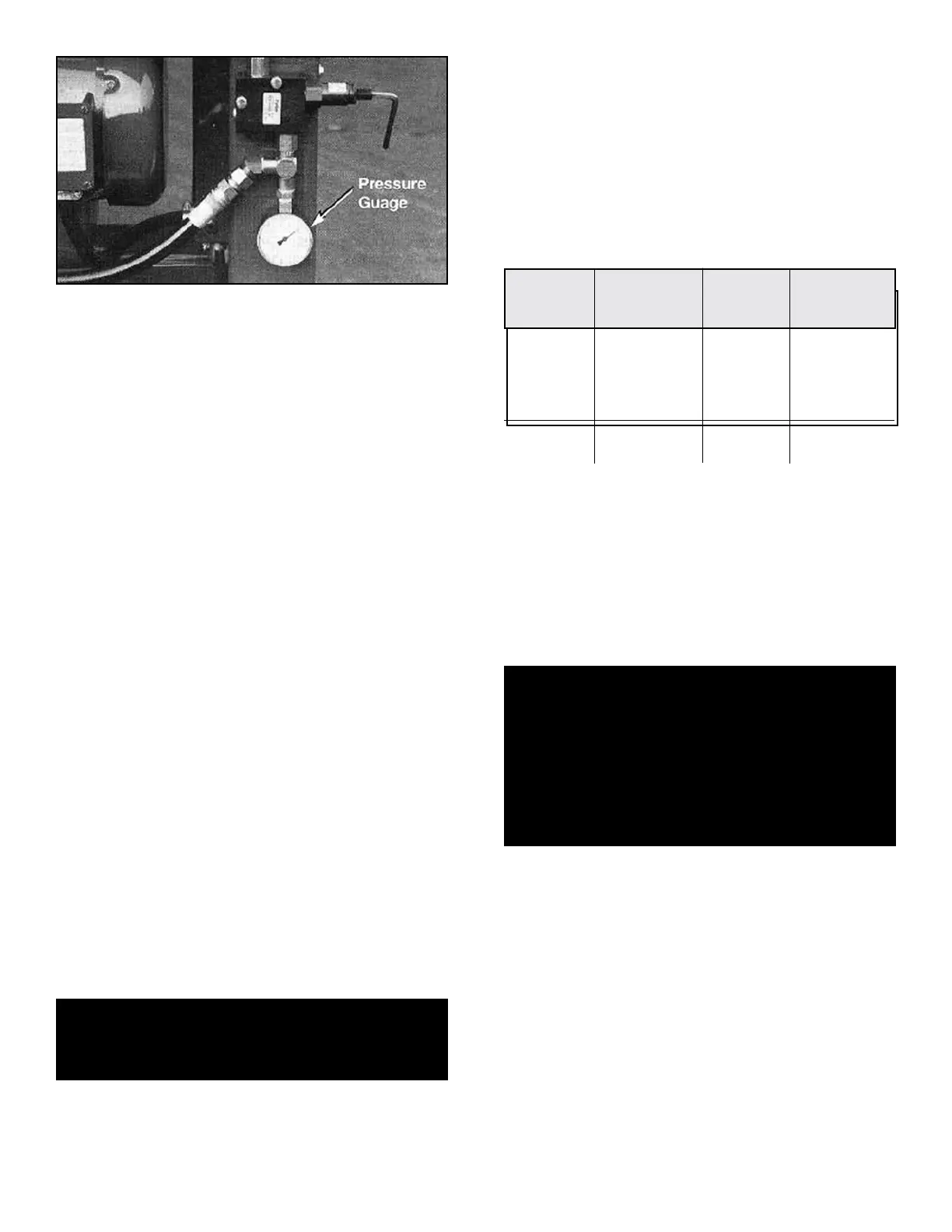

1. Tubing is not required for steps 1-3. Advance the

radius die and check the sequence valve pressure.

Sequence valve pressure is shown on the pressure

gauge attached to the valve itself. The correct pressure

will be shown only as the radius die travels forward

through the bending gates while the radius die is in

motion. Normal operating pressure should be 1600

P.S.I. The correct return pressure will be set at 300-

350 P.S.I. For bending three inch tubing, the initial

sequence valve pressure should be raised to 2000

P.S.I. for each bender (See page 33 for pressure

adjusting procedure.)

2. To raise the sequence valve pressure, turn the Allen

wrench clockwise until 2000 P.S.I. is maintained as

the radius die moves forward through the bending

gates. The return pressure will remain unchanged.

3. After proper pressures have been set, the dies

should be heavily greased.

NOTE:

Bending dies MUST be cleaned and

polished smooth for best results.

4. Position the tubing in the bender and advance the

radius die forward to begin the bending process.

Remember to USE MANUAL CONTROLS ONLY.

5. At a bend depth between 30 degrees and 40 degrees

the bender may start to “bog” down. At this time start

turning the Allen wrench counter-clockwise to reduce

the sequence valve pressure. Do not adjust below

400 P.S.I. This will allow the radius die to advance

further. Continue bending until the desired bend

depth is reached. Return the pressure to 2000 P.S.I.

for the next bend.

6. If further bends are required, repeat this procedure

for each bend. ALWAYS return the sequence valve

pressure back to 1600 P.S.l. when finished. (See

page 33 for pressure adjusting procedure.)

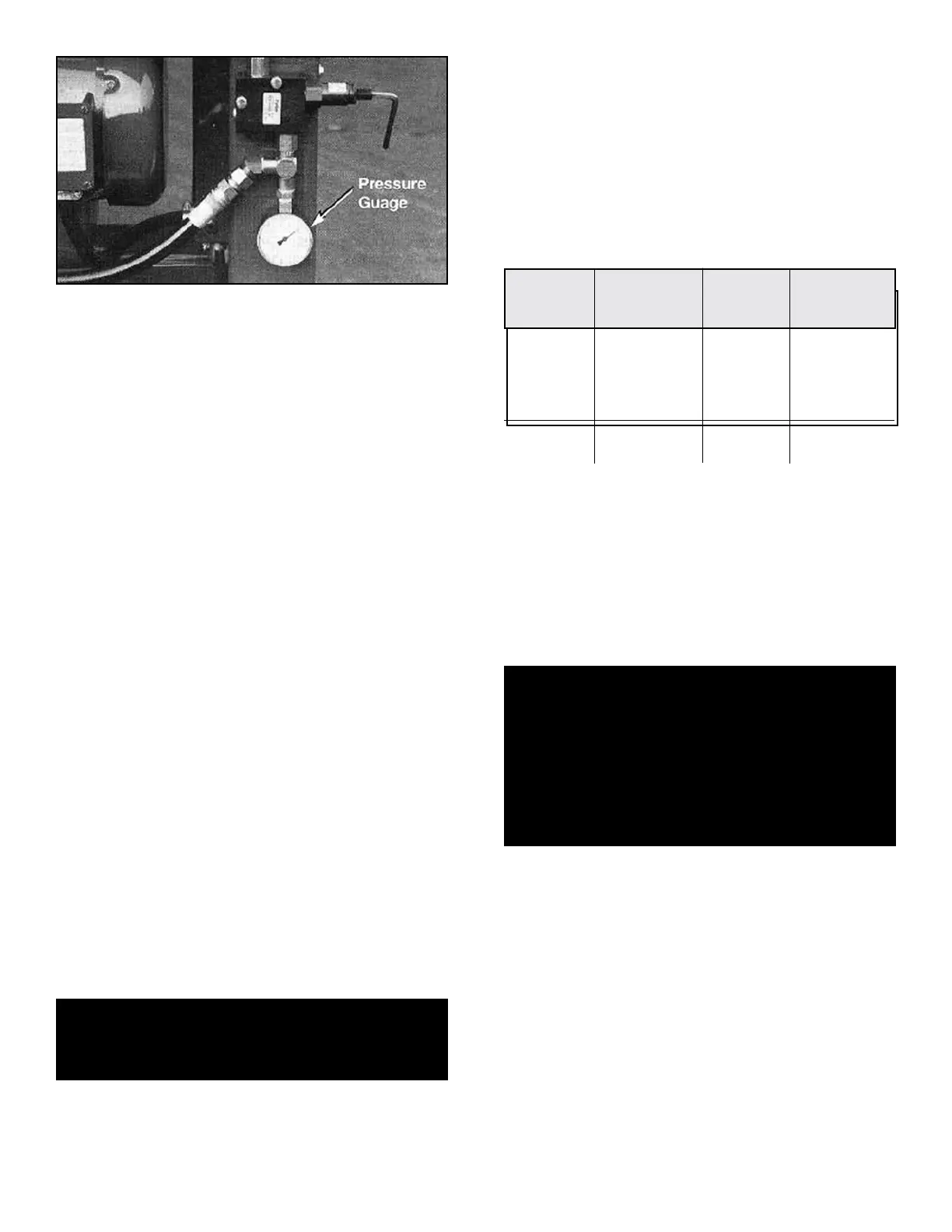

BENDING STAINLESS

TUBING

In order to get good results when bending stainless tubing, it

is necessary to increase the back shoe pressure by adjusting

the sequence valve similar to the procedure previously

described. The recommended pressures are shown below.

When using large diameter or light gauge tubing, more back

shoe pressure is required. Always remember to reset the

bender to 1600 P.S.I. when you are finished.

Stainless tubing comes in many grades. The grades

shown above are the best for bending.

NOTE:

It is very important to clean and lubricate the bending

dies during all bending procedures.

END FINISHING

OPERATIONS

USING THE INTERNAL EXPANDER

The internal expander uses segmented expander dies or

“segment sets” in conjunction with an expansion arbor.

When the arbor is pulled through the center of the seg-

ment set it spreads the “fingers” which in turn expands

the tubing to an exact inside diameter. The segment sets

are designed to work on one size arbor only. An adjust-

able Buttress Canister attached to the internal expander

cylinder is used to control the expansion range.

NOTE:

The arbor must be snug to cylinder shaft

before operation begins to avoid damaging

threads.

Recommended Tubing Proper

Tubing Size Tubing Grade Thickness Backshoe

Pressure

16 Gauge

304 or 409 only for 304

1”-2” O.D. Stainless 16 or 14 2200-2500 PSI

Tubing Gauge

For 409

2”-2-1/2” 409 Stainless

14 Gauge 2400-2700 PSI

O.D. Tubing

CAUTION!

DO NOT turn the adjustment screw beyond the end

threads of the screw,

CAUTION!

Before any attempt is made to use the end finishing

components on this machine, it is important that you

have read and fully understand all operating instruc-

tions. KEEP HANDS CLEAR of all pinch points. ONLY

TRAINED PERSONNEL should be near machine

when it is in operation. NEVER stand in front of arbor

when operating internal expander. ALWAYS wear

safety glasses when operating this machine.

Figure 3-B

Loading...

Loading...