48 Bender Operation Manual

BENDING PROBLEMS

Bending complications can be usually attributed to tubing thickness, tubing quality or improper radius

selection. The bigger the tubing diameter, the bigger the radius and wall thickness should be. See the chart

below for minimum tubing thickness and proper radius selection.

SYMPTOM / CONDITION POSSIBLE CAUSE CORRECTIVE ACTION

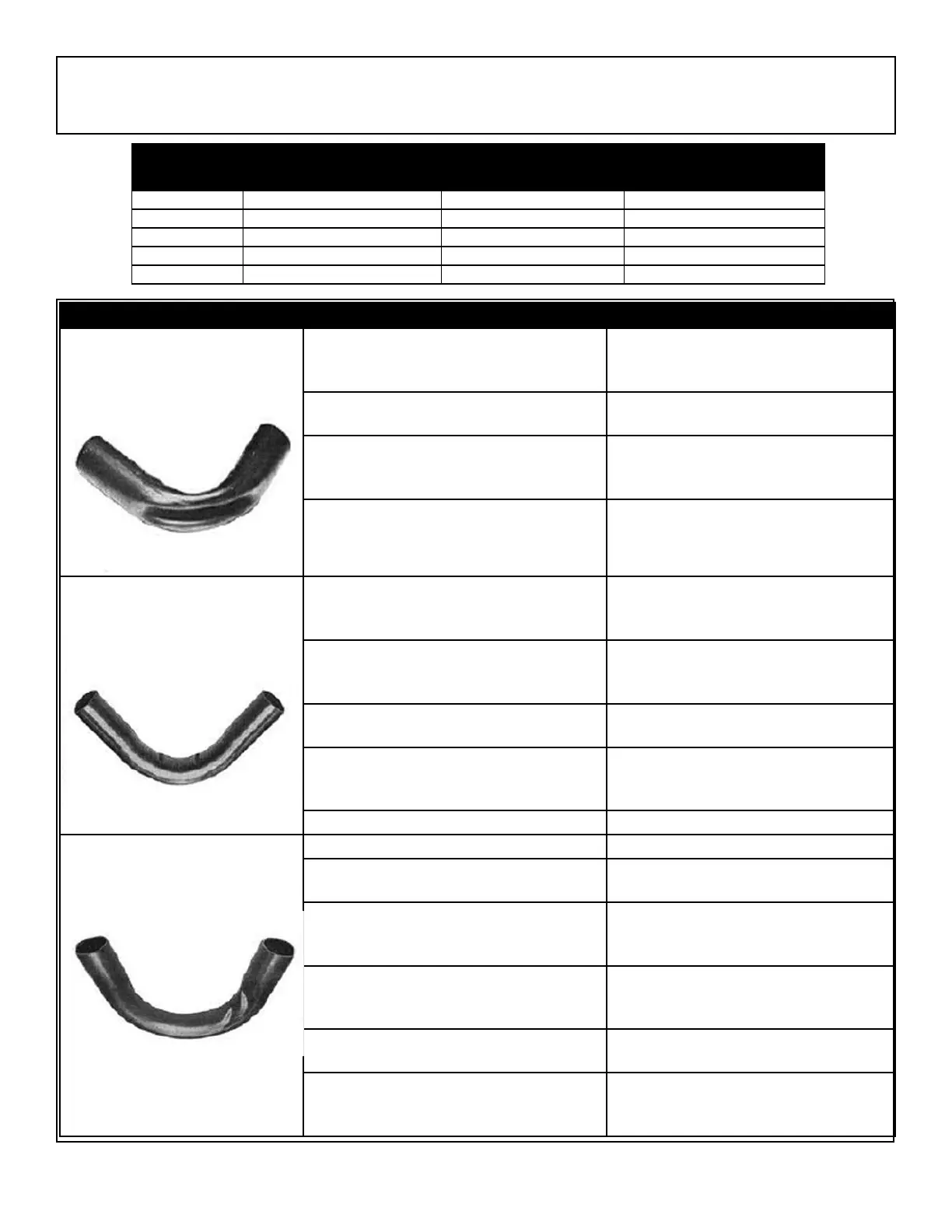

Flattening or collapsing of pipe on

outside of bend.

Incorrect back pressure. Usually a low

pressure problem.

Adjust back pressure as shown on page

33. For 3”diameter tube see bending

instructions found on page 21

Bending dies are not properly matched to

the tubing diameter.

Select proper bending dies for the

particular tubing diameter.

Tubing diameter is actually less or more

than what it is labeled.

Check the actual tubing diameter using

a micrometer or similar measuring

device.

Gauge thickness is less than the

recommended requirement. See chart

above for minimum tubing thickness.

Check tubing for proper wall thickness.

See chart above.

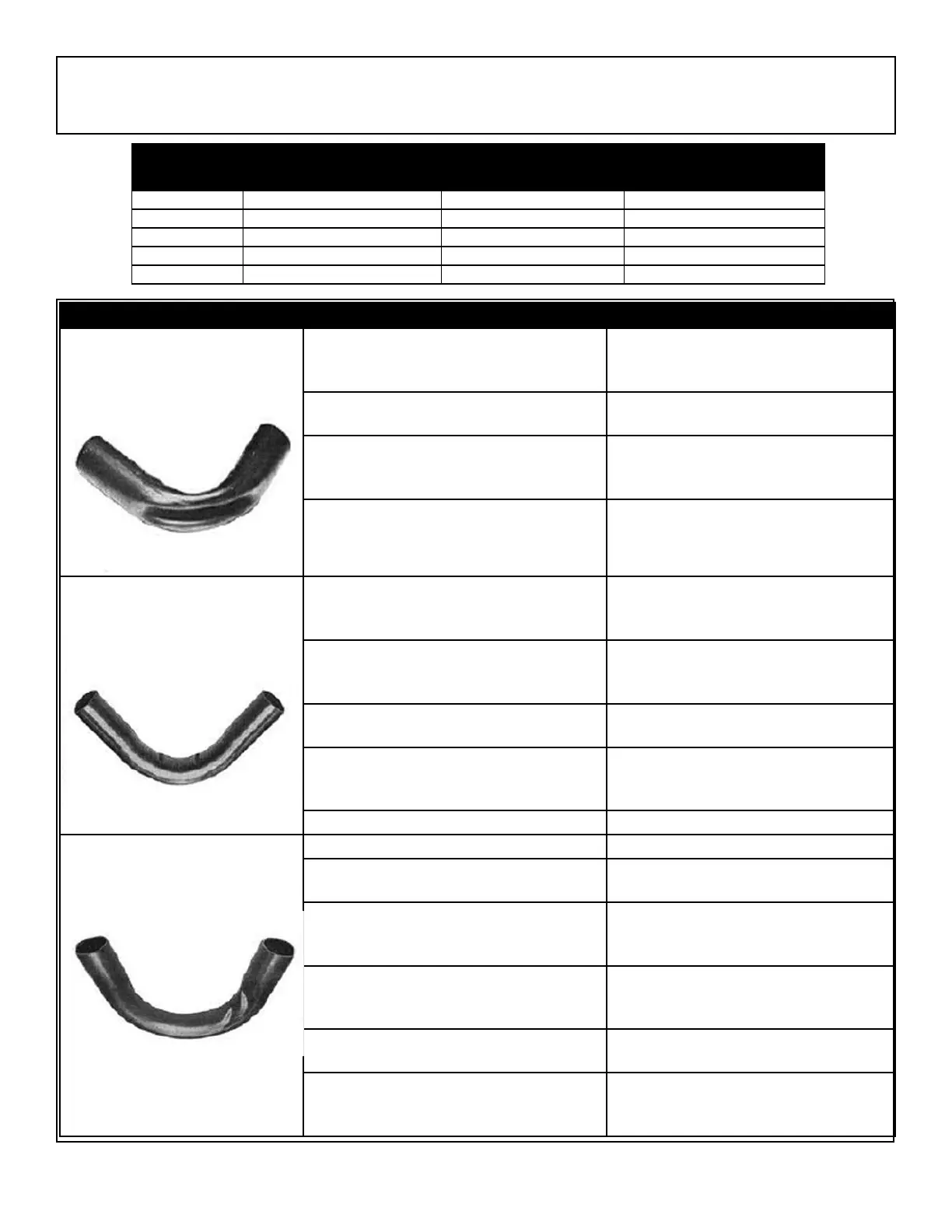

Dimpling of pipe on inside of

bend.

Incorrect back pressure. Adjust back pressure as shown on page

33. For 3” diameter tube see bending

instructions found on page 21

Gauge thickness is less than the

recommended requirement. See chart

above for minimum tubing thickness.

Check tubing for proper wall thickness.

See chart above.

Bending dies are not properly matched to

the tubing diameter.

Select proper bending dies for

the particular tubing diameter.

Tubing diameter is actually less or more

than what it is labeled.

Check the actual tubing diameter using

a micrometer or similar measuring

devise.

Improper chain adjustment. Adjust chains as described on page 34.

Crimping or wrinkling of pipe. Improper die alignment. Check the following.

Bronze barrel bushings may be worn. Remove and replace the bushings as

described onpage 36.

Guide plate may be mis-aligned. Check

proper alignment as described on page

35.

Adjust and shim guide plate as described

on page 35.

Pusher block may be worn. Check for

proper tolerance as described on page

38.

Remove and replace pusher block as

required.

Bending dies are not properly matched to

the tubing diameter.

Select proper bending dies for

the particular tubing diameter.

Tubing diameter is actually less or more

than what it is labeled.

Check the actual tubing diameter using

a micrometer or similar measuring

device.

Tubing Diameter Minimum Tubing Thickness

5" Radius

Minimum Tubing Thickness

4" Radius

Minimum Tubing Thickness

3 1/2" Radius

1”- 1-3/4” 18 Gauge / .049 16 Gauge / .065 16 Gauge / .065

1-7/8” - 2” 16 Gauge / .065 16 Gauge / .065 16 Gauge / .065

2-1/4” 16 Gauge / .065 14 Gauge / .083 14 Gauge / .083

2-1/2” 14 Gauge / .083 14 Gauge / .083 N/A

3” 13 Gauge / .095 N/A N/A

Loading...

Loading...