15 Bender Operation Manual

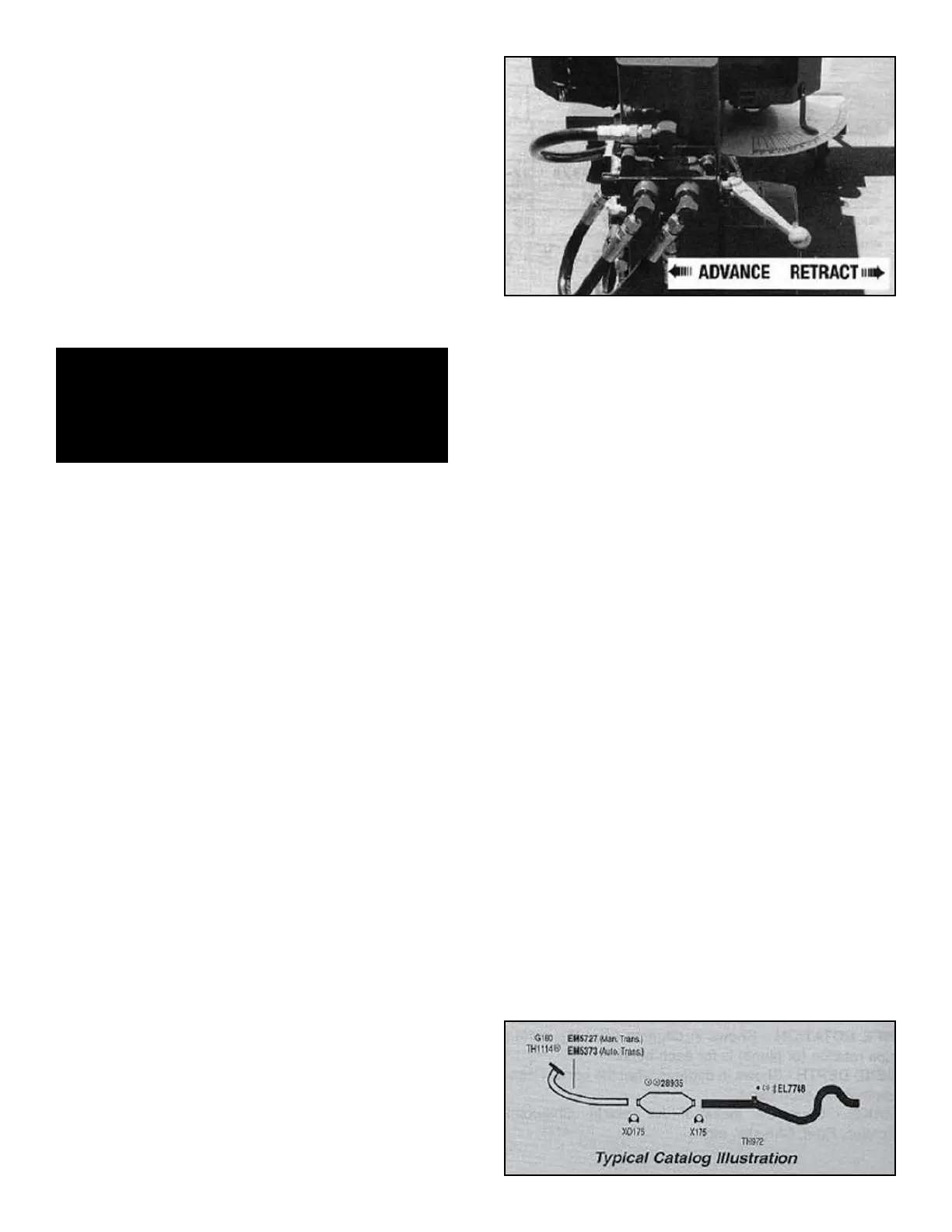

To use the three-button automatic controls, follow these

simple instructions.

1. Position the “Auto-Stop” pointer at the desired depth

of bend.

2. Position the tubing at the appropriate bend mark.

3. Check your “circle-of-swing” and prepare to begin

bending.

4. Press the GREEN control button.

5. At this time the radius die will advance until the

desired depth-of-bend is reached, then, retract to the

original starting position.

6. Be prepared to support the tubing as it is released

from the dies.

USING THE REMOTE FOOT SWITCHES - The remote

foot switches are used for manual bending functions.

When using the foot switches for manual operation it is

best that you position the “Auto-Stop” pointer out of the

way or at 180 degrees so that it does not interfere. If you

want to use the foot pedals in conjunction with the “Auto-

Stop” pointer, position the pointer at the desired bend

depth and proceed by pressing the RIGHT foot switch

until the radius die stops at the pre-set bend angle.

Press the LEFT foot switch to retract the radius die.

Always be prepared to support the pipe as it is released

from the dies.

OPERATING THE MANUAL

KNEE CONTROL.

“BL” / BULLET MODELS

Read the following section completely before attempting

any operation of this unit. All “BL” models are equipped

with a hydraulic control valve mounted at knee height

that allows the user to operate the machine manually

with their leg. A degree plate with pointer is mounted

near the front of the machine that gives the user accu-

rate bend depths. “BL” models are not equipped with any

automatic features.

To operate the manual control valve, move the handle to

the left or the plunger down to advance the radius die.

The handle must be fully engaged to properly control

radius die movement.

To retract the radius die, move the handle to the right (or

plunger up) to return to the original starting position.

Always be prepared to support the pipe as it is released

from the dies.

OPERATION NOTE / BL MODELS:

If the operating control handle is pressed half way or par-

tially down during the bending operation, the radius die

may slow down or even retract slightly. To keep the

bending die at a controlled speed you must fully depress

the valve handle. If you wish to advance the radius die a

few degrees only, instead of easing the handle down, try

“tapping” the handle.

BENDING OPERATIONS

There are basically two styles of bending that can be per-

formed on your new bender. The first is PROGRAM CARD

BENDING which requires the use of PROGRAM CARDS

that contain instructional data for specific applications.

The second is PATTERN BENDING which is the most

popular method and duplicates pipes by using an existing

pipe or wire pattern as a master.

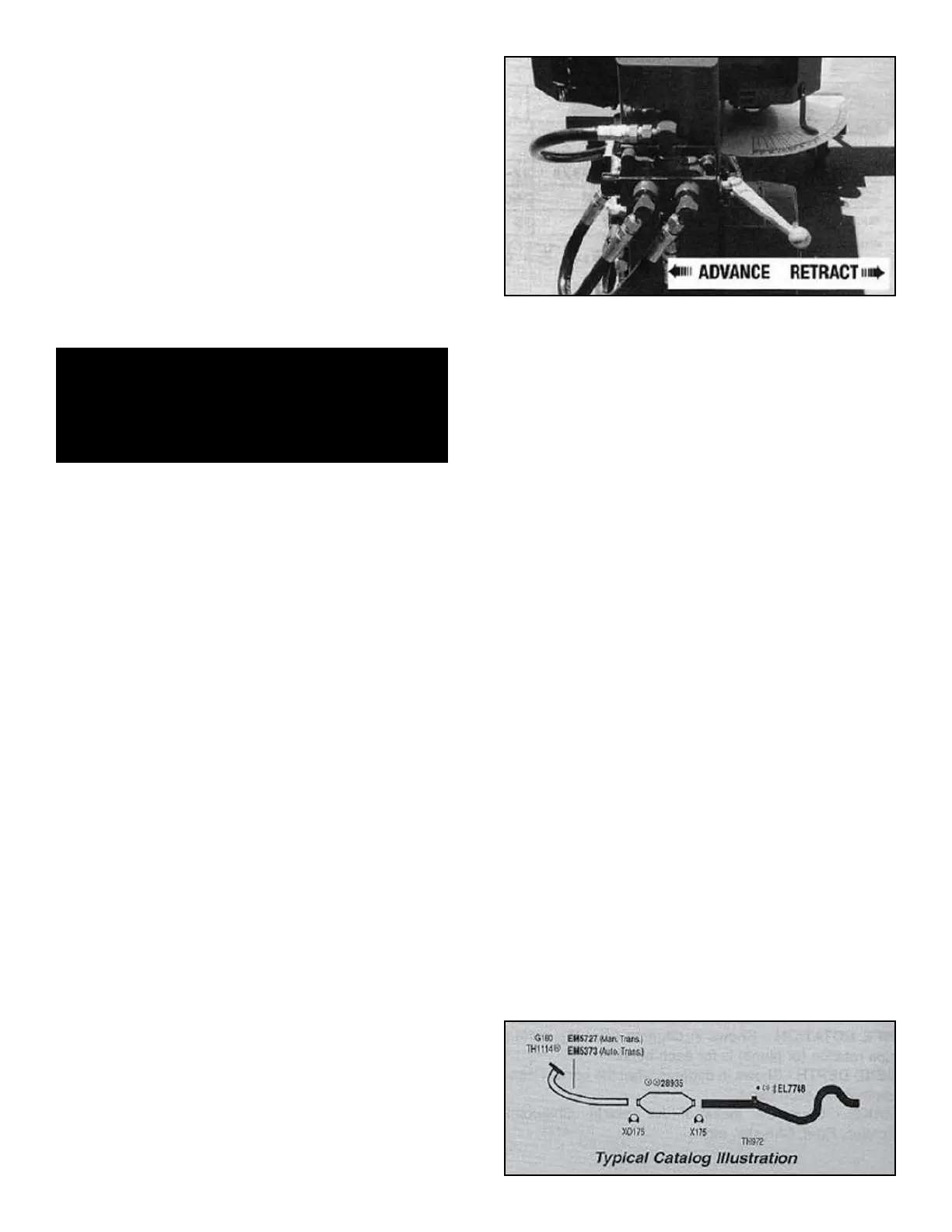

USING THE PROGRAM CARDS - The Program Card

System contains bending data for specific applications.

The following instructions define each section of the card.

It is important that you read the entire card carefully before

attempting to bend. Due to the many cards and applica-

tions covered, there may be some inaccuracies. No

responsibility is assumed by the manufacturer for any

consequences arising from inaccuracies found on the pro-

gram cards.

Look up the card number in the appropriate reference

catalog. Exhaust pipes numbers start with the letter “E”

and tail pipes numbers start with the letter “T”.

Bender Operation Manual 15

CAUTION!

Be alert at all times. NEVER place hands near

bending area or other pinch points

when motor is running.

Loading...

Loading...