5. Snug the collar back into the clamp blocks by gently

pushing back on the collar assembly.

6. Slowly, while depressing the valve handle down,

move the shaft forward until the tool enters the

tubing. Be sure that the tool is centered with the

tubing.

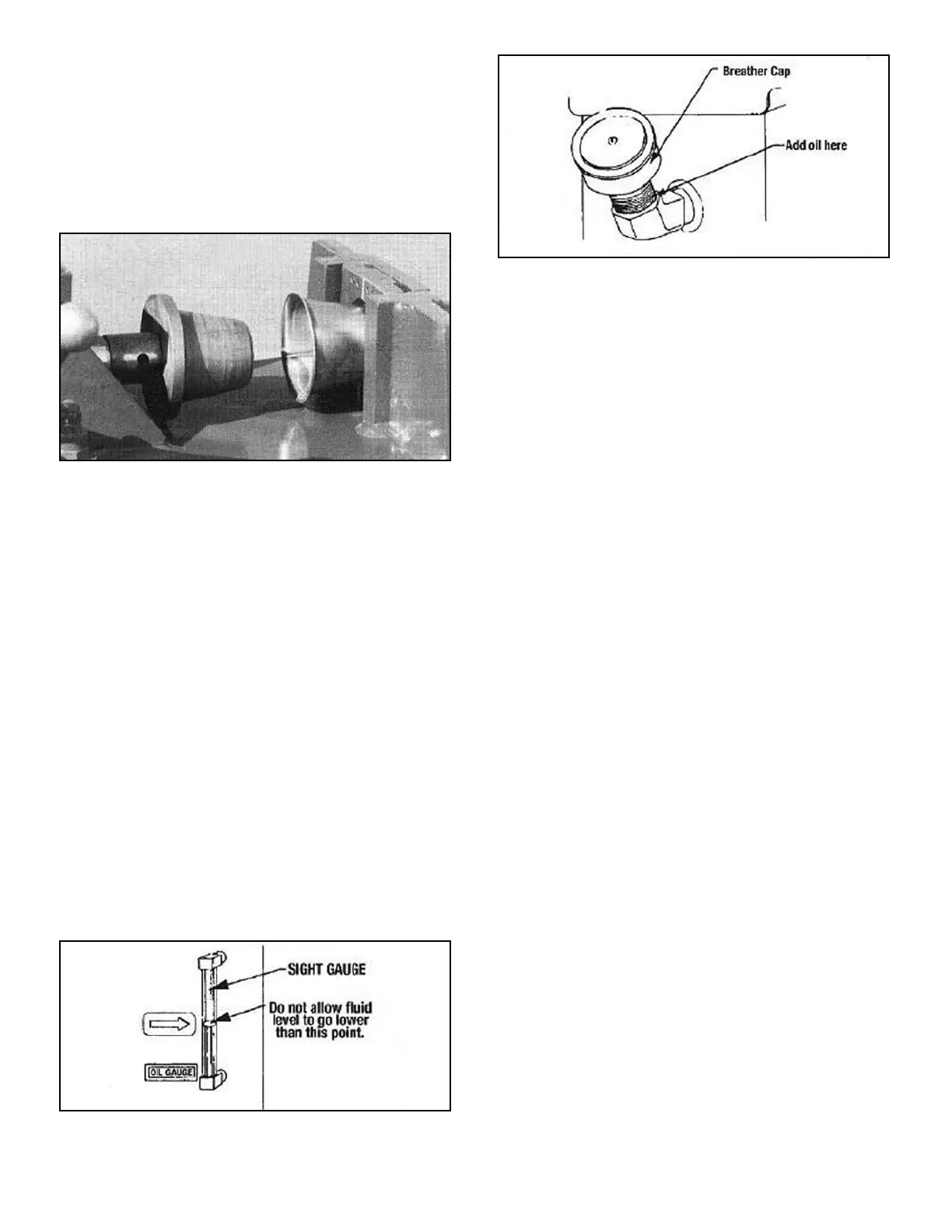

7. Make the collector flange by advancing the tool

forward until the cylinder stops. Apply full pressure

for this operation. (See figure 3-A)

8. Retract the die by lifting up on the control handle.

9. Separate the collar from the tubing. Remove tooling

and return to the storage area.

MAINTENANCE

Your new bender was designed and built for years of

dependable service. The following maintenance schedule

has been formulated to produce satisfactory performance

and longevity of your machine. Reasonable care and

daily observation of wear items will supplement this

schedule and result in a prolonged service life.

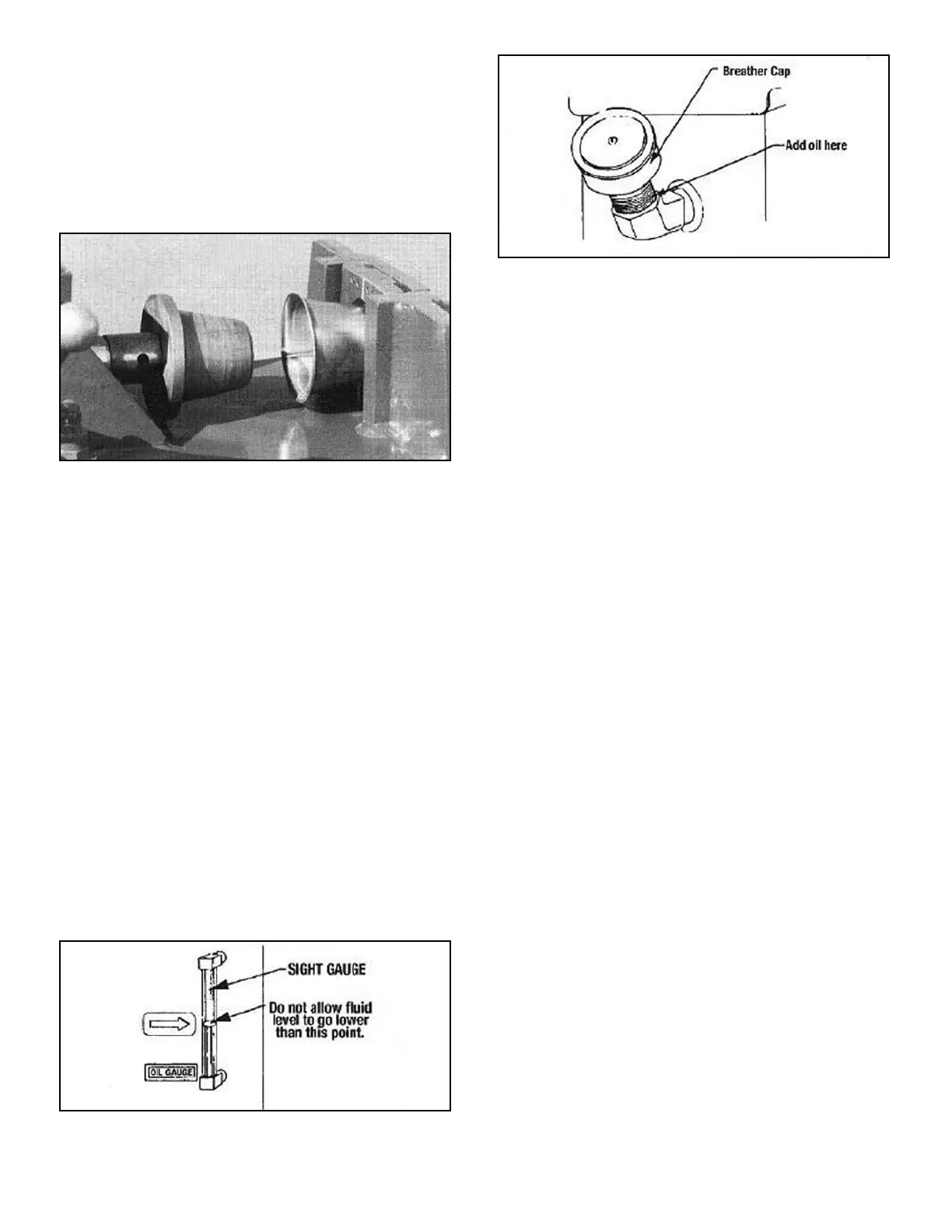

HYDRAULIC OIL

Your new bender was shipped with approximately seven

gallons of hydraulic oil. The correct oil level will be shown

on the sight gauge located to the rear right of the

machine. To properly check the oil level, proceed as fol-

lows.

1. Advance the radius die until it just comes in contact

with the back shoes.

2. At this time visually check the oil by observing the oil

sight gauge. At the proper level, oil should appear

midway on the gauge.

3. If oil cannot be seen, it will necessary to add oil via

the fIller cap located on the reservoir.

If the oil level continues to drop and oil needs to be

added frequently, the machine should be

checked thoroughly for possible leaks.

Any of the following hydraulic oils may be used.

Make Brand

Chevron OC Turbine 46

Mobile DTE Medium

Texaco Rando HD 46

Conoco Turbine 46

Shell Shell Turbo 46

Citgo AW46

Pennzoil Zoil Medium or No.10

Union 76 UNAX AW46

If the above brands are not available, use any

10 medium weight mineral based hydraulic

fluid with a non-foaming additive.

NOTE:

The hydraulic oil should be changed after 1,500

hours of operation or yearly, whichever comes first.

The oil filter should also be changed at this time.

RECOMMENDED WEEKLY MAINTENANCE

Clean and re-grease guide plate, arbor and swager

clamp blocks.

Check for equal chain tension. (See page 34)

t Check all pressures. (See page 33)

t Inspect all hydraulic hoses for wear or cuts. Replace

faulty hoses.

t Check for hydraulic leaks. Repair leaks immediately.

RECOMMENDED MONTHLY MAINTENANCE

t Check depth-of-bend for accuracy.

(See pages 39 & 4O)

t Grease zirk fittings on barrel assembly.

t Clean and spray all dies with rust inhibitor.

t Tighten all hydraulic hoses as required. Do not

over-tighten.

t Check squareness of back gates and level guide

plate. Shim / adjust as required. (See page 35)

t Re-torque mounting bolts and nuts on all hydraulic

components.

t Lubricate caster assemblies.

t Remove any nicks or burrs from tooling with a small

file.

Snug arbor and ST-1 to cylinder shaft.

32 Bender Operation Manual

Figure 3-A

Loading...

Loading...