45 Bender Operation Manual

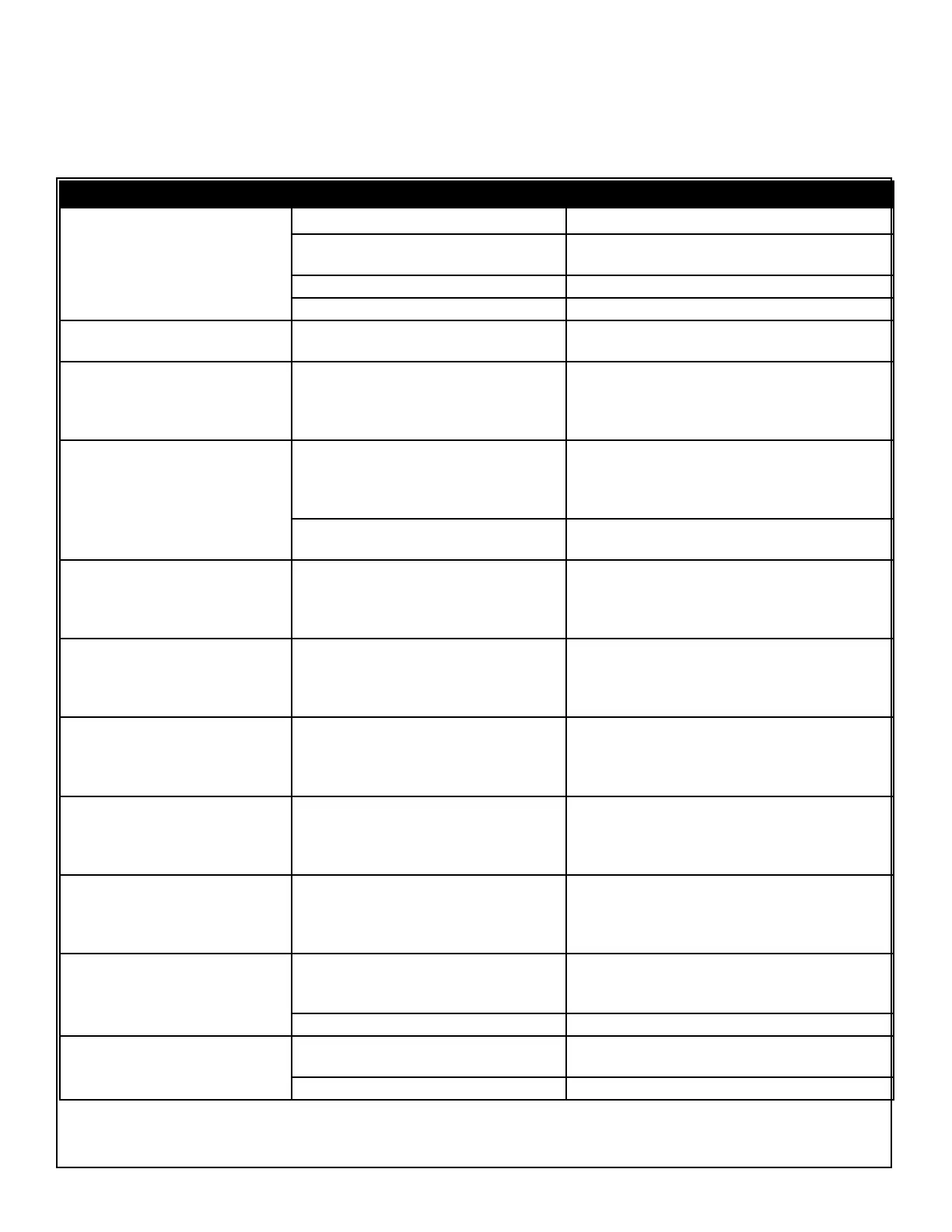

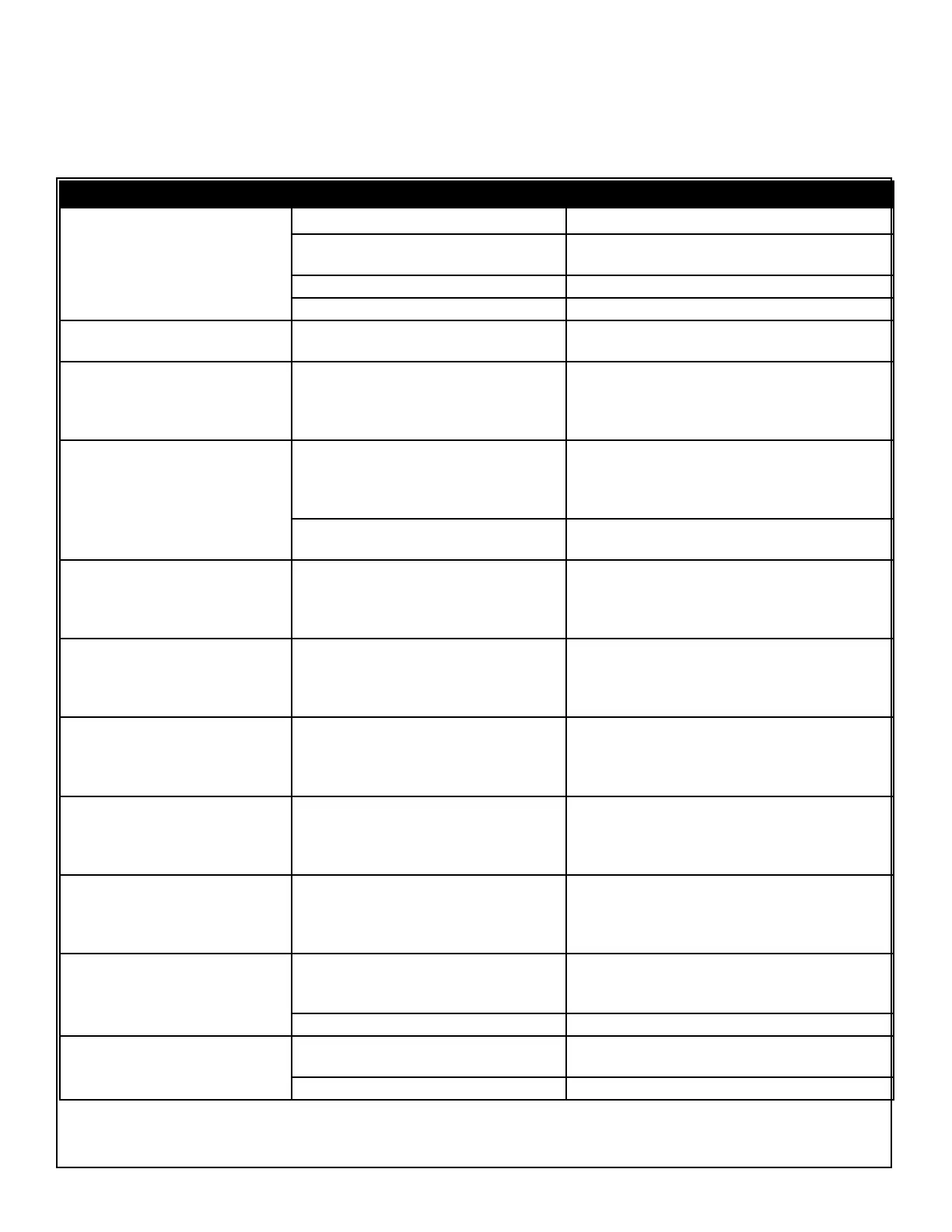

SYMPTOM / CONDITION POSSIBLE CAUSE CORRECTIVE ACTION

The motor does not run Circuit breaker(s) is off Turn breaker(s) on

Incorrect wiring. Check voltage supply, phase and wiring. Refer to

wiring instructions found on pages 49-50

Heater in switch box has been tripped. Check thermal heaters(s) See page 44.

Defective electric starter / motor. Test and replace as needed.

The motor smokes. Power supply incorrect. Check voltage supply, phase and wiring. Refer to

wiring instructions found on pages 7 & 43

The motor shuts off. Thermal overload tripping. Check voltage supply, phase and wiring. Refer to

wiring instructions found on pages 7 & 43. If prob-

lem persists, check wiring for short circuits. Check

amp draw. Refer to motor nameplate.

The bender gives off shocks. The plug has been wired wrong.

Power is connected to the ground

wire.

Check plug. Make sure that the green wire on the

power cord is used for grounding purposes only.

NO POWER should be connected to the green

ground wire.

Power wire has become disconnected

in the switch box or motor.

Check all connections.

The tubing wrinkles or kinks. Incorrect guide plate alignment, worn

barrel bushings or pusher block.

Tubing gauge is not adequate for that

particular size or radius.

See page 48 for improving bend quality.

The bender experiences loss of

power. The motor stalls even though

the system pressure is showing

less than 2000 psi.

Incorrect wiring. Voltage or amperage

too low.

Check voltage supply, phase and wiring. Refer to

wiring instructions found on pages 7 & 43.

BA / BAS models - Bending ram will

retract with the button controls but

not with the left foot switch.

Left foot switch is inoperative or wire

has become disconnected

Check connections on micro switch. Refer to

diagrams on pages 49-50. Check micro switch with

ohmmeter. See page 43. Check for broken or

disconnected wires.

BA / BAS models - The top cylinder

will advance with the button

controls but not with the right foot

switch.

Right foot switch is inoperative or wire

has become disconnected

Check connections on micro switch. Refer to

diagrams on pages 49-50 Check micro switch with

ohmmeter. See page 43. Check for broken or

disconnected wires.

The sequence valve pressure

surges high when trying to retract

the bending ram.

The return pressure is set too high.

The top cylinder is trying to overcome

the bottom cylinder which is not

retracting simultaneously

Adjust return pressure as shown on page 33.

The back gates remain in the open

position even after the bending ram

is retracted.

Tubing is not sliding back with the

radius die after the bend is made,

causing the gates to remain open.

Clean and thoroughly grease bending dies

before use. Wipe tubing clean.

Return pressure is set too low. Adjust return pressure as shown on page 33.

The swager cylinder does not

expand the tubing straight.

The swager cylinder is not aligned

correctly.

Shim the swager cylinder as required. See

page 37.

The swager cylinder is bent. Remove and replace swager cylinder

Bender Operation Manual 45

TROUBLESHOOTlNG

Introduction;

The troubleshooting procedures shown on the following pages contain certain systems and/or conditions, possible causes

and the corrective actions required. The chart gives the easiest corrective action first, then proceeds with more difficult procedures.

Be certain that the person(s) working on the machine have the ability to do the service. Only certified electricians should

work on electrical components. ALWAYS unplug the machine before servicing.

Loading...

Loading...