5. Loosen the set screw on the adjustable trip arm

located directly underneath the depth-of bend plate

and adjust so that it just activates the micro switch.

6. Re-tighten the set screw.

7. Retract the radius die and re-check.

8. If further adjustment is required, repeat steps.

CALIBRATING THE DIGITAL

READOUT DISPLAY /

“BA”MODELS

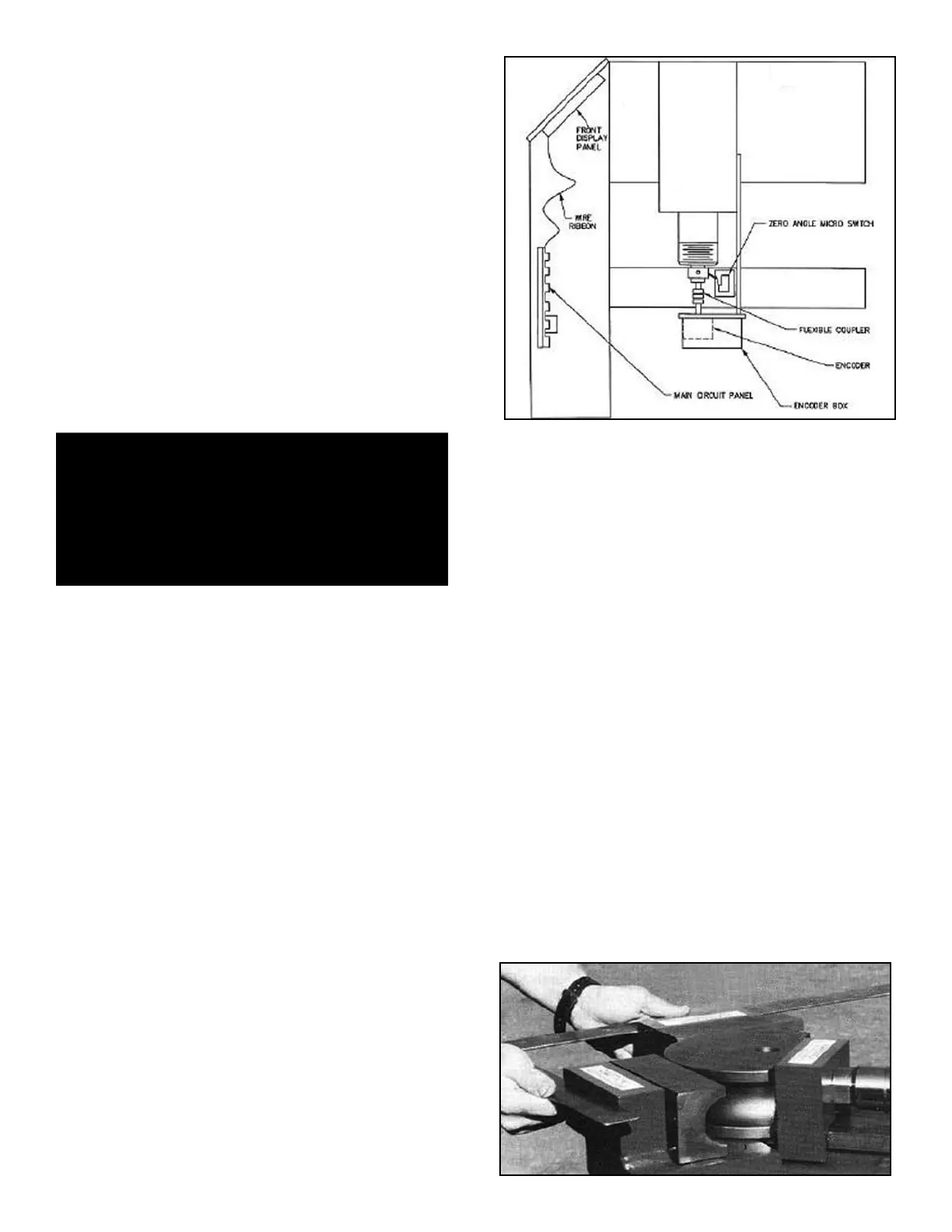

Automatic depth-of-bend and digital readout functions on

all “BA” models are performed by an electronics package

consisting of three main components. The circuit board

assembly, digital encoder and the zero angle micro

switch. (See figure 3-C)

t Circuit board assembly - The printed circuit board

is made up of three basic components. The main circuit

panel, front display panel and wire ribbon that connects

the two. The main circuit panel is held in position by

“card guides” and then plugged into a “pin-edge” connec-

tor mounted internally in the front upright of the bender. A

bypass board for trouble shooting is also attached

(stored) “piggyback” style on the back of the main circuit

panel. (See page 41 for proper use of jumper board.)

t Digital encoder - The digital encoder is located just

below the right side gate assembly and enclosed in a

metal box. As the encoder rotates by the means of a

flexible coupler attached to the barrel shaft, it registers

degrees and shares this information with the main circuit

panel.

t Zero angle micro switch - The zero angle micro

switch is located up front just below the right side gate

assembly and attached to the bender frame. The zero

angle micro switch has three distinct functions.

1. lnitiates the counting cycle and serves as an adjust-

ment device for properly calibrating the die angle.

2. Resets the die angle to zero upon retraction of the

radius die.

3. Advances the “steps” in the STATION window when

using the MEMORY function.

NOTE:

Only slight adjustments of 4 degrees or less can be

made to the die angle reading on digital models. The

digital readout is accurately maintained with the help

of logic functions in the digital control

board and optical sensors of the encoder. The

system automatically re-calibrates itself upon full

retraction of the radius die as the zero angle micro

switch is tripped. By adjusting the trip arm that

activates the zero angle micro switch you can

effectively “stall” or advance the counting process

which will in turn change the die angle reading. If

the die angle appears to be more than 5 degrees

out of calibration it is most likely a faulty encoder.

Dirt, oil or moisture will contaminate the encoder

and cause it to malfunction. If the encoder

becomes contaminated, remove from the machine

and clean with alcohol or T.V. tuner spray.

DO NOT use harsh or oil based solvents.

To properly calibrate the digital readout, follow the steps

outlined below.

1. Turn the machine on.

2. Place a set of bending dies in position.

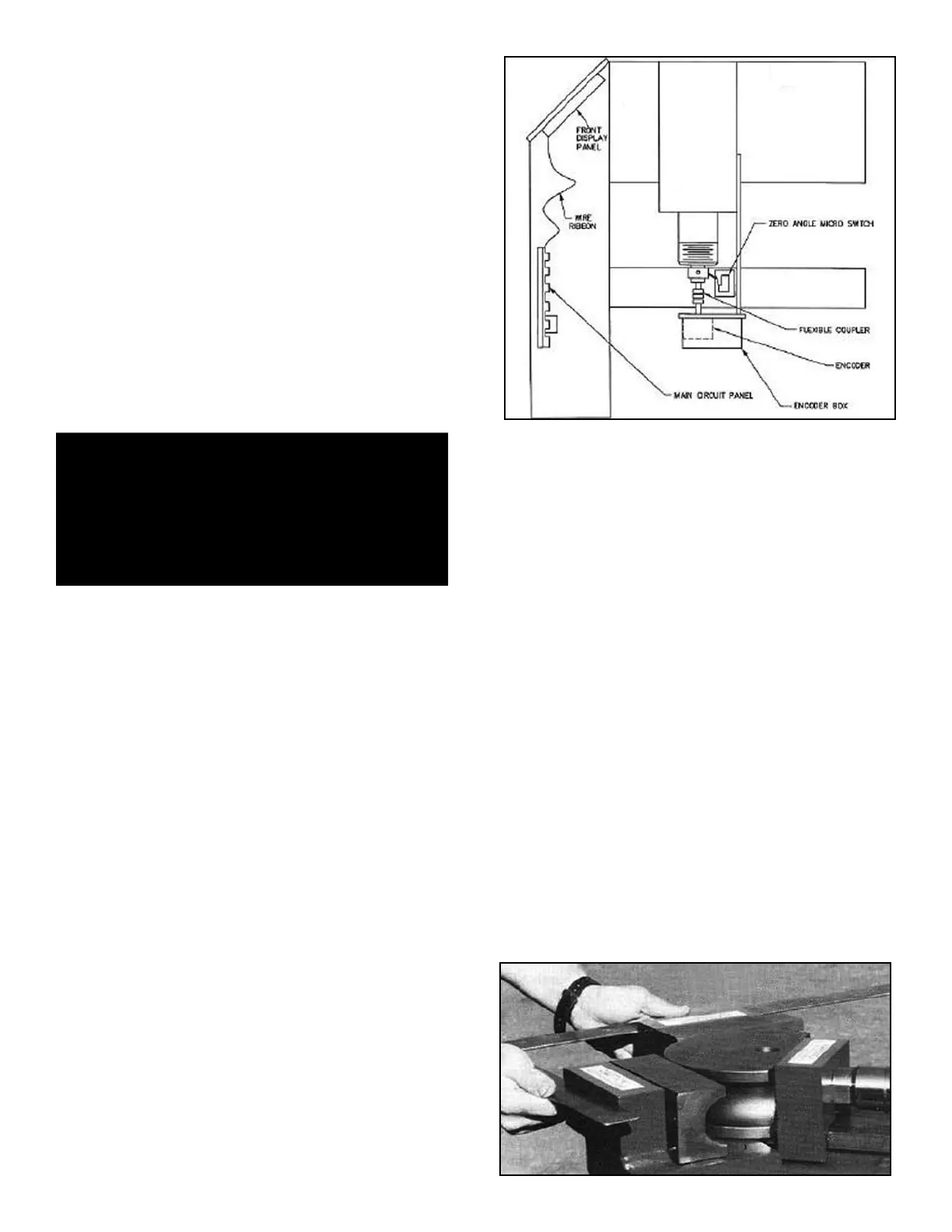

3. Using a carpenters square, advance the radius die

until the back gates are at a true 90 degrees, con-

tacting the inside of the square evenly across the

front. (See figure 1-A)

40 Bender Operation Manual

DANGER!

This machine contains high voltage. Disconnect power

at the receptacle before performing any electrical

repairs. Secure plug so that it cannot be accidentally

plugged in during service.

Figure 1-A

Figure 13-C

Loading...

Loading...