7.5.6 DC Brake Timing

The MX

2

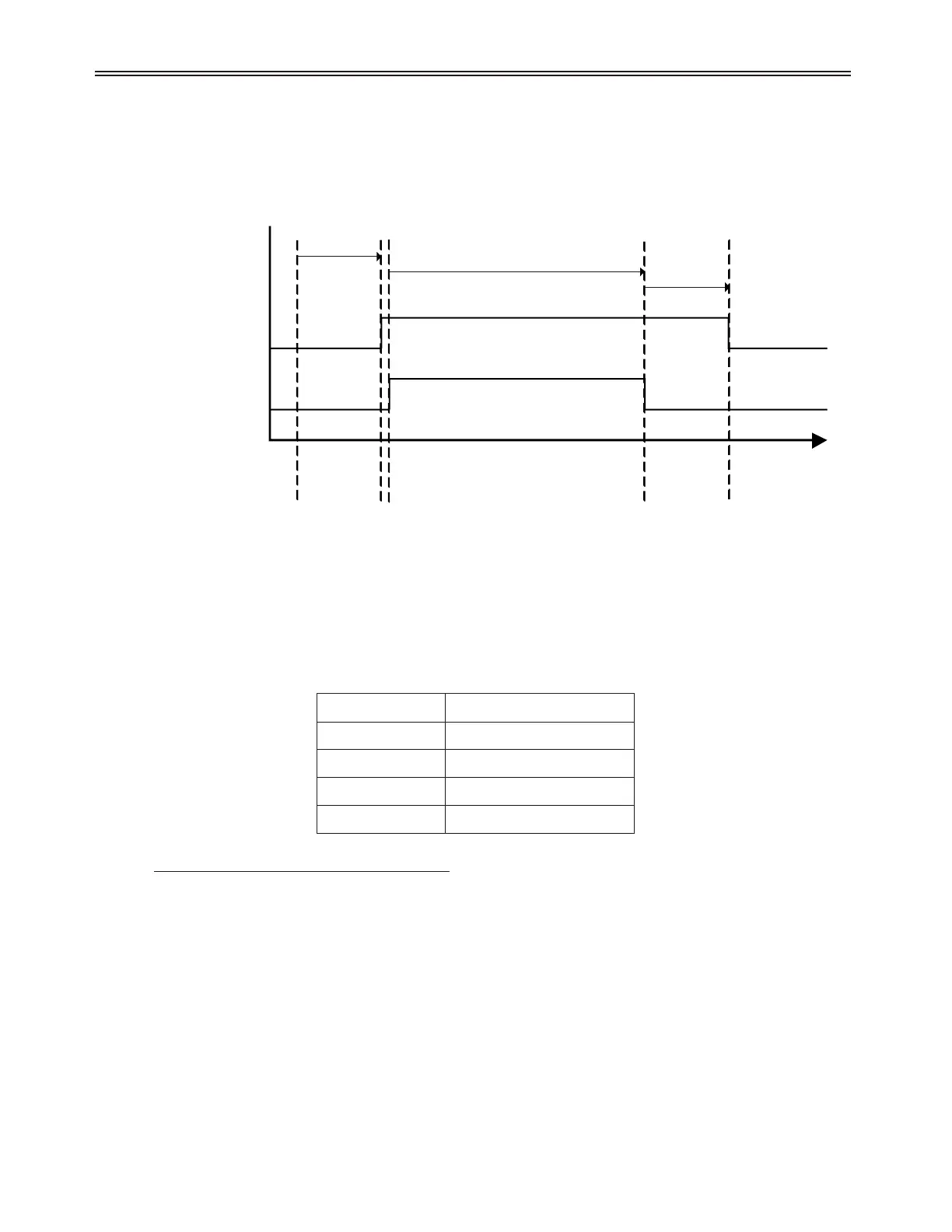

DC injection brake timing is shown below:

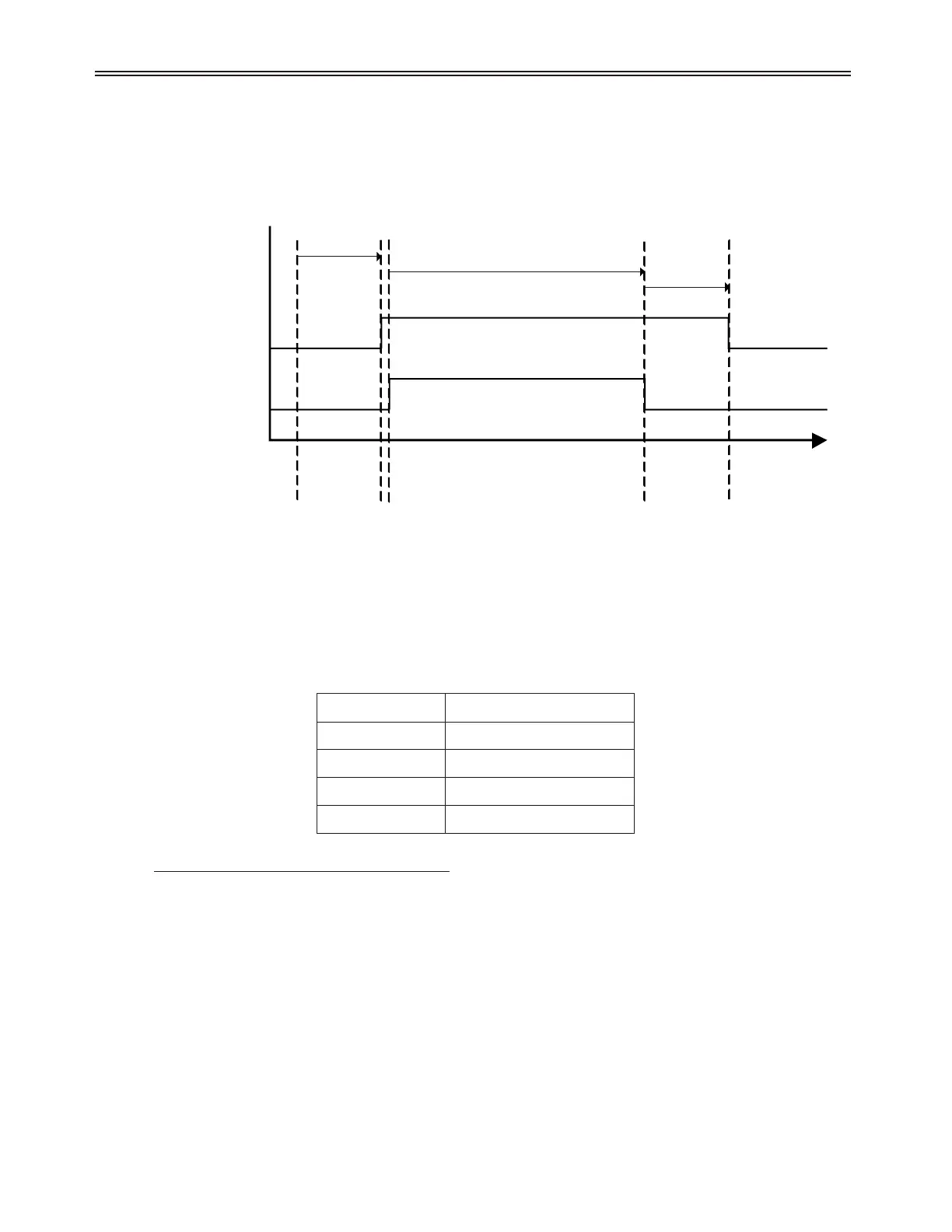

After the DC Brake Time has expired, the Braking Relay is held energized to allow the DC current to decay before opening the

freewheel path. This delay prevents a contactor (if used) from having to open significant DC current which greatly prolongs the life of

the contactor. This delay time is based on motor FLA, the larger the motor the longer the delay time. The delay after DC brake time is

approximately:

Motor Overload Calculations During DC Injection Braking

During DC braking the MX

2

Solid State Motor Overload Protection is fully active. During braking the Running Motor Overload setting

is used. The MX

2

adjusts the overload calculations based on whether Standard Duty or Heavy Duty braking is used. The overload

calculations are also adjusted based on whether the standard Current Transformers (CTs) are used for current feedback or if the optional

Hall Effect Current sensor is used for current feedback.

z NOTE: Discretion must be used when DC injection braking. Motor heating during DC injection braking is similar to motor heating

during starting. Although the Motor OL is active (if it has not been intentionally disabled), excessive rotor heating could still result if the

load inertia is very large, braking level is high, or the brake time is set too long. Caution must be used to assure that the motor has the

thermal capacity to brake the desired load in the desired period of time without excessive heating.

154

7 - THEORY OF OPERATION

Stop

Commanded

time

DC Brake

Delay Time

DC Brake

Time

Starter SCRs On, DC Current Applied

DC Injection On

DC Injection Off

Braking Relay Energized

DC Brake

Time

Expired

Delay to allow

contactor to

close before

applying DC

current

Braking Relay

opens after a

delay to allow

residual DC

current to decay

Delay after

DC Brake

Brake Relay Off

Brake Relay On

Figure 38: DC Injection Brake Timing

Motor FLA Delay after DC Brake Time

10 A 0.4 seconds

100 A 0.8 seconds

500 A 2.3 seconds

1000 A 4.3 seconds

Loading...

Loading...