7-2

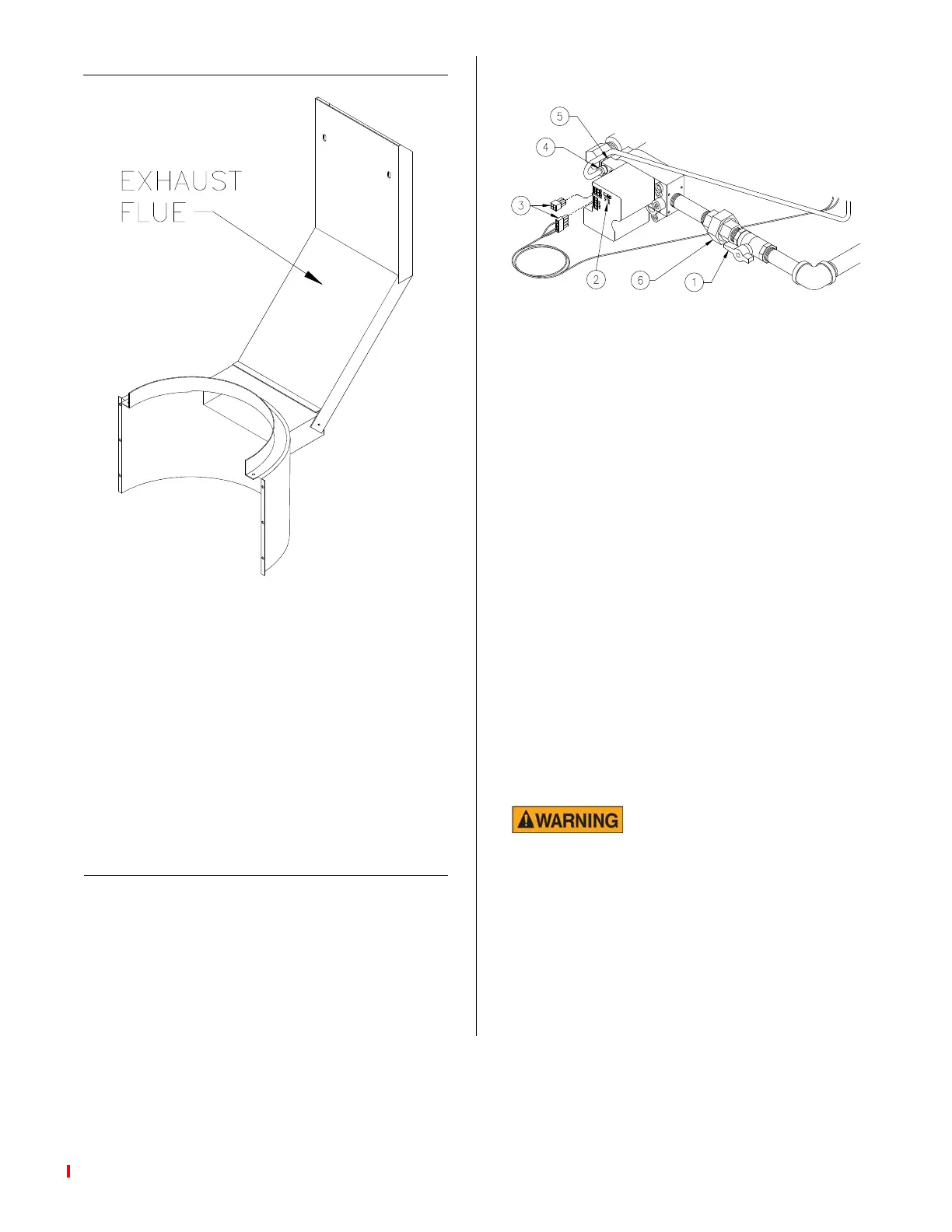

VENTILATION

• Never modify exhaust flue! Back pres-

sures from added extensions can cause

high ambient temperatures near the

controls.

• Make sure unit is correctly ventilated.

Restrictions, drafts or other adverse

conditions might affect proper operation

of the burner and combustion assem-

blies.

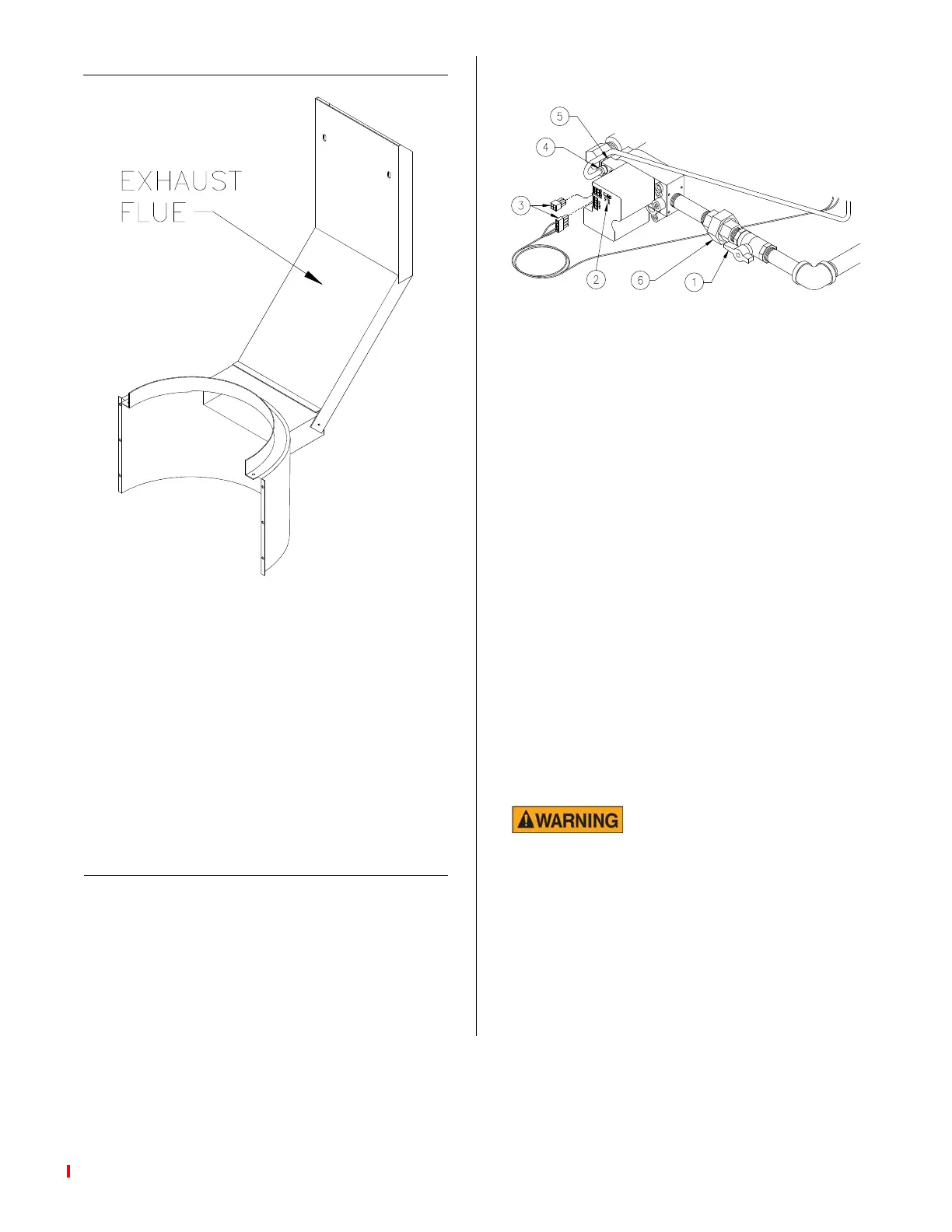

GAS VALVE

Regulates gas supply. The gas valve has a

two position switch*: OFF to stop all gas

flow, and ON allows gas flow to pilot and

main burners as needed. Adjustment for

gas pressure and gas flow to pilot burner

are also found on the valve.

Replacement:

1. Turn power switch, manual gas shut

off valve (1) and switch (2) OFF.

2. Turn main gas supply OFF.

3. Disconnect main electric supply.

4. Remove condensate pan and front

panel.

5. Disconnect gas valve wire harnesses

(3).

6. Loosen fitting (4) that mounts pilot

burner gas supply line to gas valve.

7. Loosen brass union elbow (5).

8. Loosen pipe union (6).

9. Remove piping from gas valve.

Be sure pilot burner gas

supply line is fully

installed into gas valve fitting during

installation. If not, a gas leak may be the

result.

10. Install in reverse order. Use gas pipe

sealer on pipe threads. Check all gas

connections and pipes with a soap

and water solution. Bubbles indicate a

gas leak.

broaster.com Manuals #17280 1/15 Rev 12/15

Loading...

Loading...