Confidential

2-63

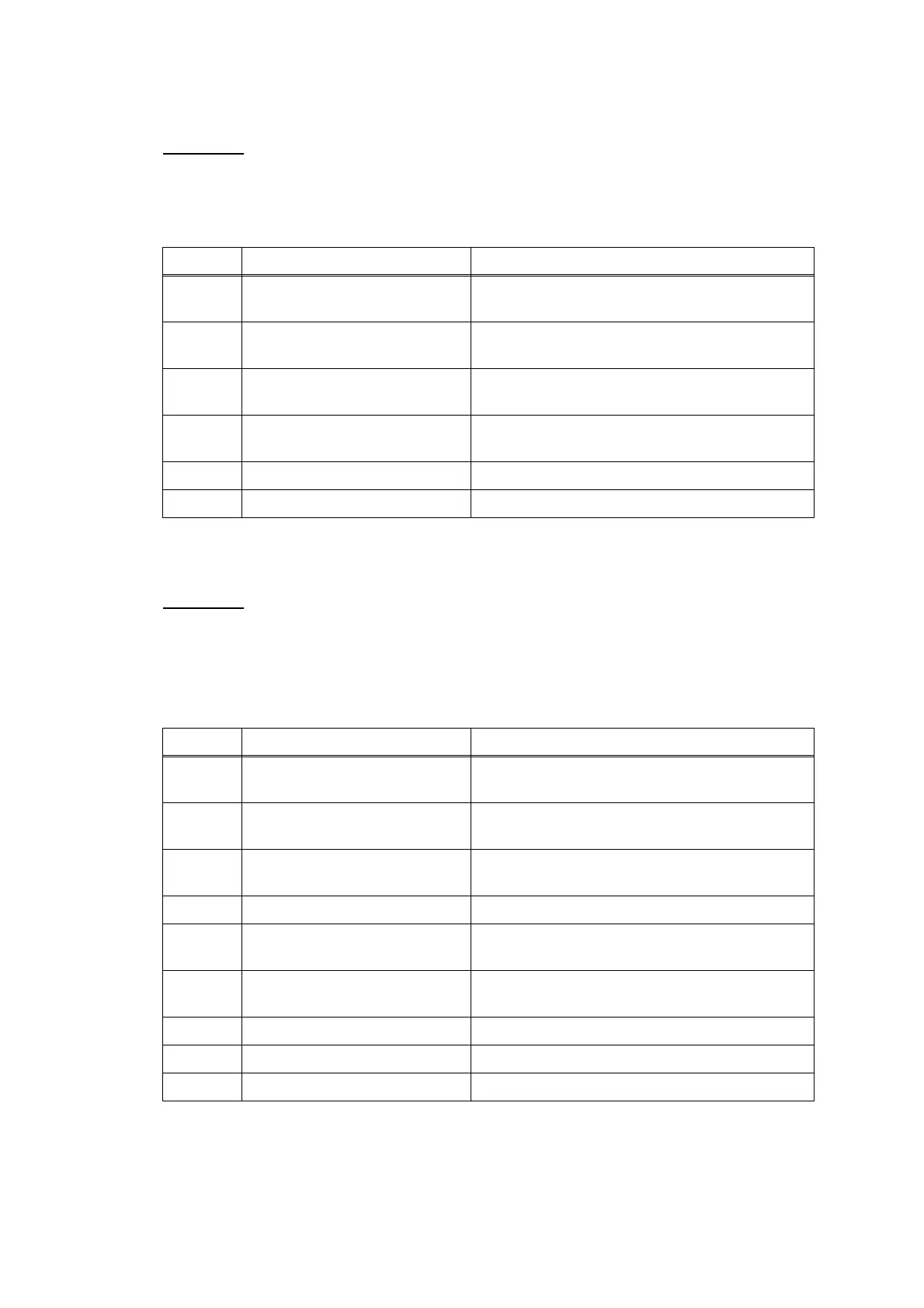

Paper jam around paper ejection parts

User Check

- Clean the related rollers.

- Check that the number of recording paper on the paper ejecting tray is within the maximum

ejecting paper volume.

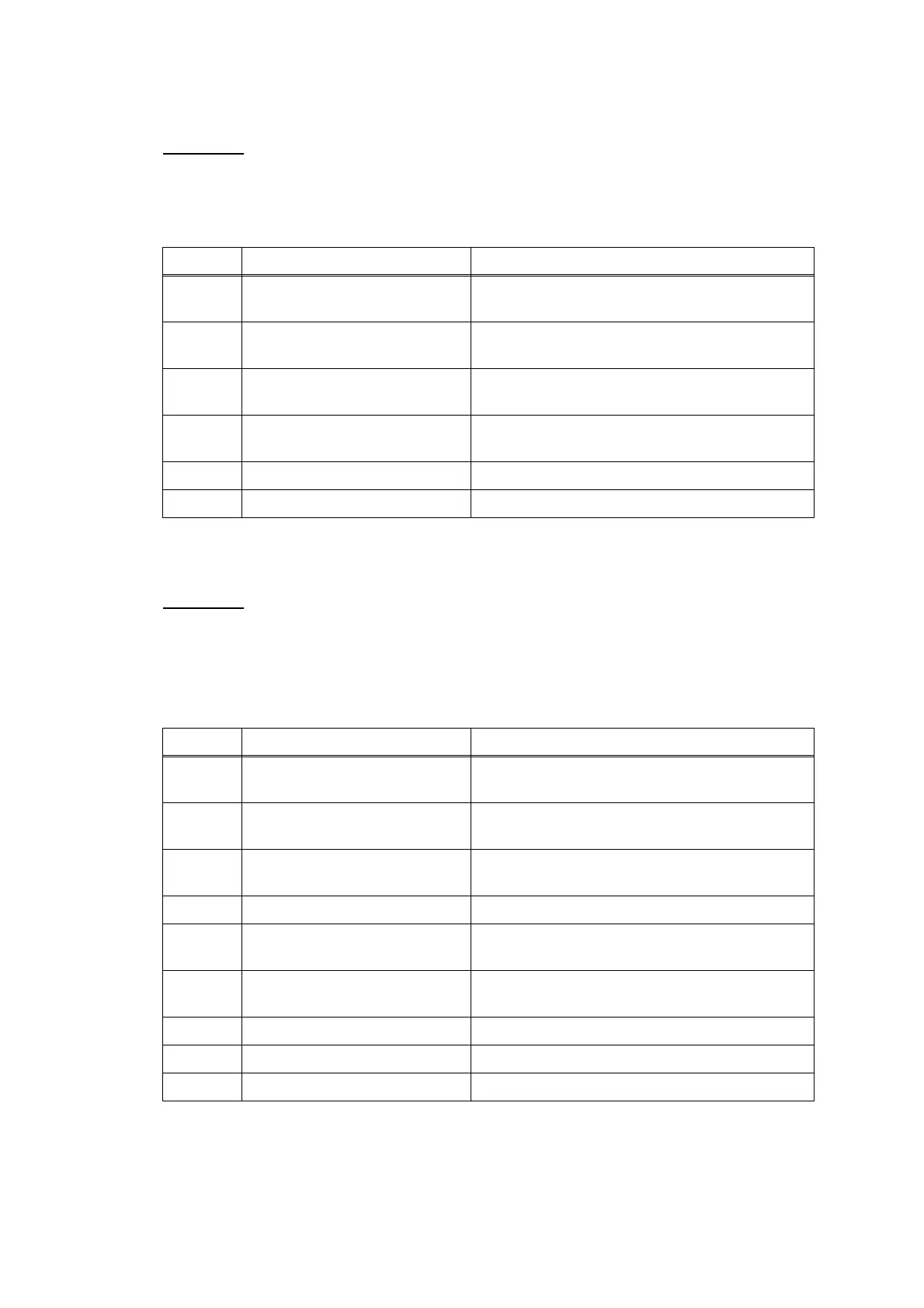

Paper jam during duplex printing

User Check

- Adjust the paper guide to match the recording paper size.

- Check that the paper shorter than the specified size is not loaded.

- Check thickness of recording paper is within tolerance of each type.

- Clean the related rollers.

Step Cause Solution

1 Foreign materials in the recording

paper path

Remove foreign materials.

2 Switchback inner paper guide not

mounted in place

Set the switchback inner paper guide into place.

3 Switchback outer paper guide not

mounted in place

Set the switchback outer paper guide into place.

4 Paper ejection roller belt out of

place

Set the paper ejection roller belt into place.

5 Paper ejection roller belt broken Replace the paper ejection roller belt.

6 Main PCB defective Replace the main PCB ASSY.

Step Cause Solution

1 Foreign materials in the recording

paper path

Remove foreign materials.

2 Switchback inner paper guide not

mounted in place

Set the switchback inner paper guide into place.

3 Switchback outer paper guide not

mounted in place

Set the switchback outer paper guide into place.

4 Switchback roller belt out of place Set the switchback roller belt into place.

5 Paper ejection roller belt out of

place

Set the paper ejection roller belt into place.

6 DX paper guide ASSY not

mounted in place

Set the DX paper guide ASSY into place.

7 Switchback roller belt broken Replace the switchback roller belt.

8 Paper ejection roller belt broken Replace the paper ejection roller belt.

9 Main PCB defective Replace the main PCB ASSY.

Loading...

Loading...