42

ZTKS0164 / Z31949 / 06

Troubleshooting

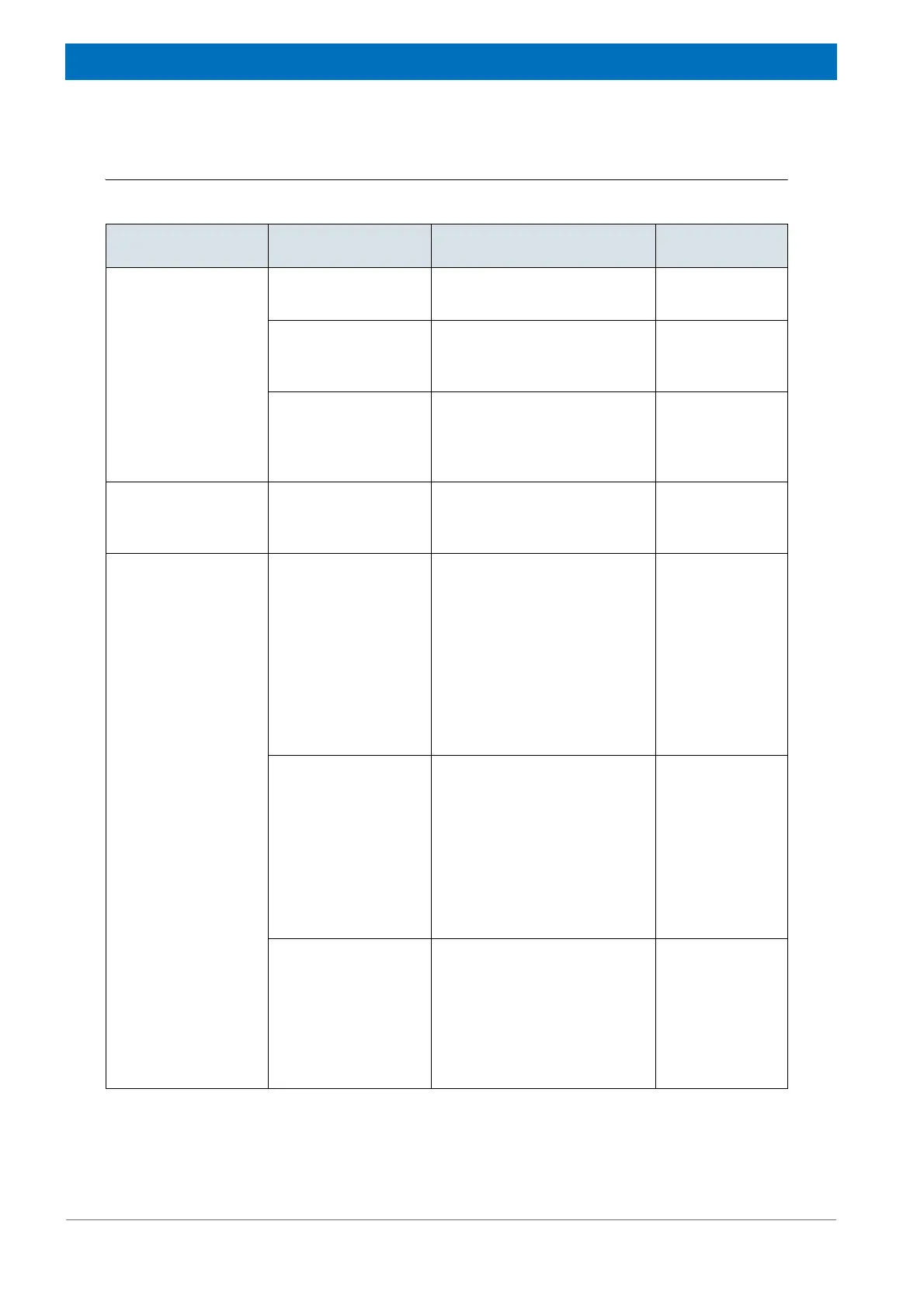

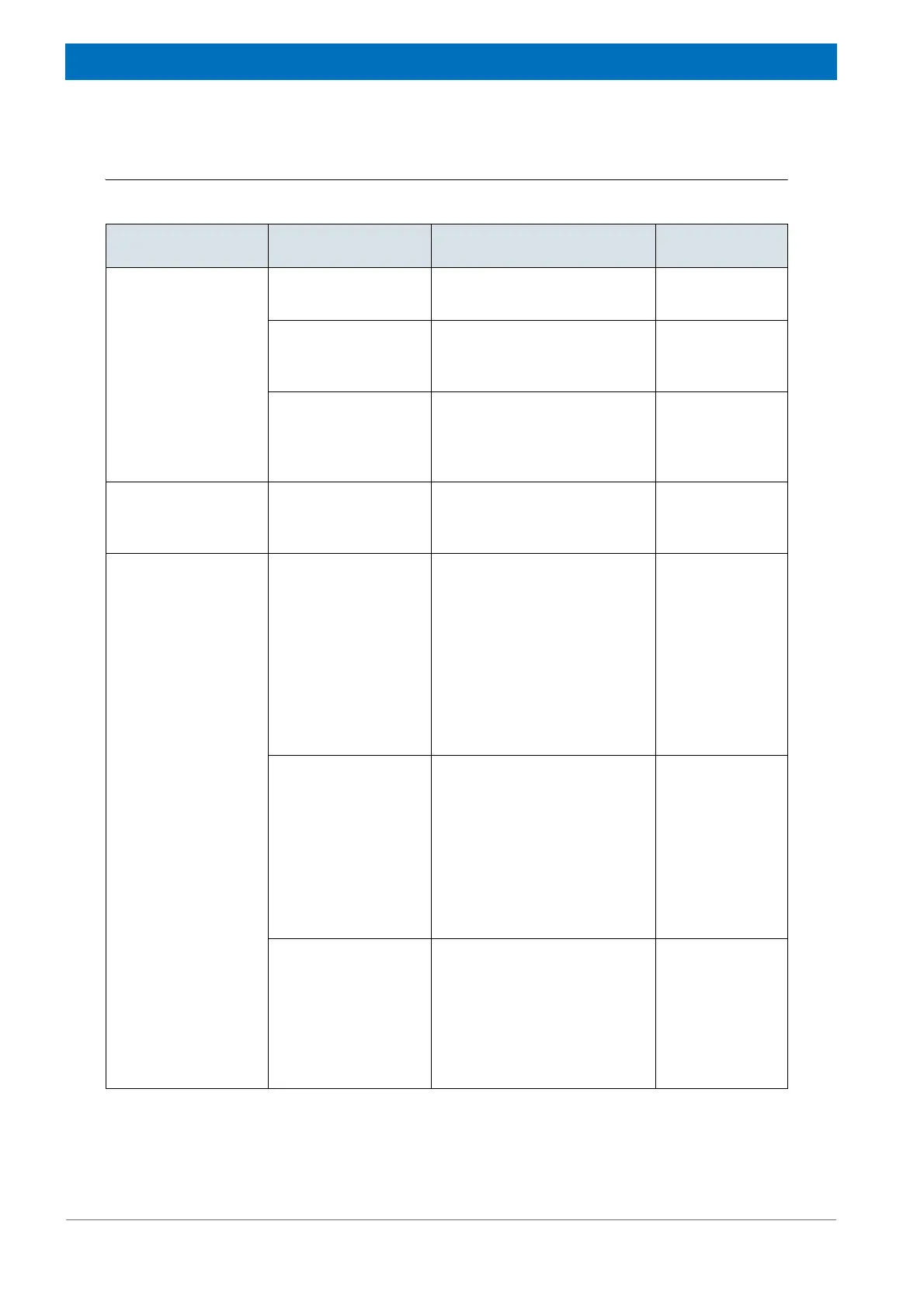

6.2.3 During Cooling Procedure

a. See note on previous page.

Indicator Possible reason Solution Performed by

Cooling with liquid

nitrogen is too

slow.

Empty transporta-

tion dewar.

Refill or replace transporta-

tion dewar.

Bruker Service

Transfer pressure

too low.

Increase transfer pressure

slightly (max. pressure

0.3 bar).

Bruker Service

Transportation

dewar is leaky; no

transfer pressure

can be applied.

Check transportation dewar

and replace if necessary.

Bruker Service

Precooling with

liquid nitrogen

occurs too quickly.

Transfer pressure

too high.

Stop cooling. Adjust correct

transfer pressure.

Bruker Service

Vacuum in RT

vessel does not

reach

5 x 10

-5

mbar

within 48 hours.

O-rings are leaky. Check and clean O-rings

and slots. If necessary,

replace the O-rings for

• the vacuum valve

• the drop-off plate

• the reduction and

sealing flanges

• the bottom plate

a

.

Bruker Service

O-rings are frozen

due to contact with

liquid nitrogen.

1. Stop cooling.

2. Warm O-rings with

warm air.

3. Wait until the vacuum is

recovered.

4. Prevent liquid nitrogen

from splashing on

O-rings.

Bruker Service

Pumping unit or

pumping line is

defective.

Check pumping unit and

pumping line:

A vacuum of at least

10

-6

mbar must be reached

while the sealing plug is

closed.

Replace if necessary.

Bruker Service

Loading...

Loading...