3

Design and Function

10/47 ekr CON 600, ekr CON 600 net – Master-Slave Guiding with Sensor Positioner

The number of required edge sensors depends on the desired

guiding modes.

Master-Slave Guiding Possible Guiding Modes Reference Point for Guiding

with two edge sensors Web edge guiding left or right web edge

with four edge sensors

Web edge guiding left and right web edge

Web center-line guiding web center-line

With the displayed version of the master-slave guiding with four

edge sensors, sensors 3 and 4 detect the position of the unguided

MASTER web and sensors 1 and 2 the position of the guided SLAVE

web (following web). If the MASTER web moves laterally to the

web running direction during the laminating process, the control

automatically guides the SLAVE web by the respective adjusting

movement of the guiding device (e. g. rotating frame guide).

In this way, during web edge guiding the master-slave guiding

keeps the preset distance (offset) of both web edges constant

(offset ≠ 0) or ensures that both web edges are positioned pre-

cisely over one another (offset = 0).

During web center-line guiding the master-slave guiding ensures

that the SLAVE web is guided exactly to the middle of the MASTER

web (offset = 0) or that the lateral displacement between the cen-

ter-lines of the SLAVE and the MASTER web remains constant (off-

set ≠ 0).

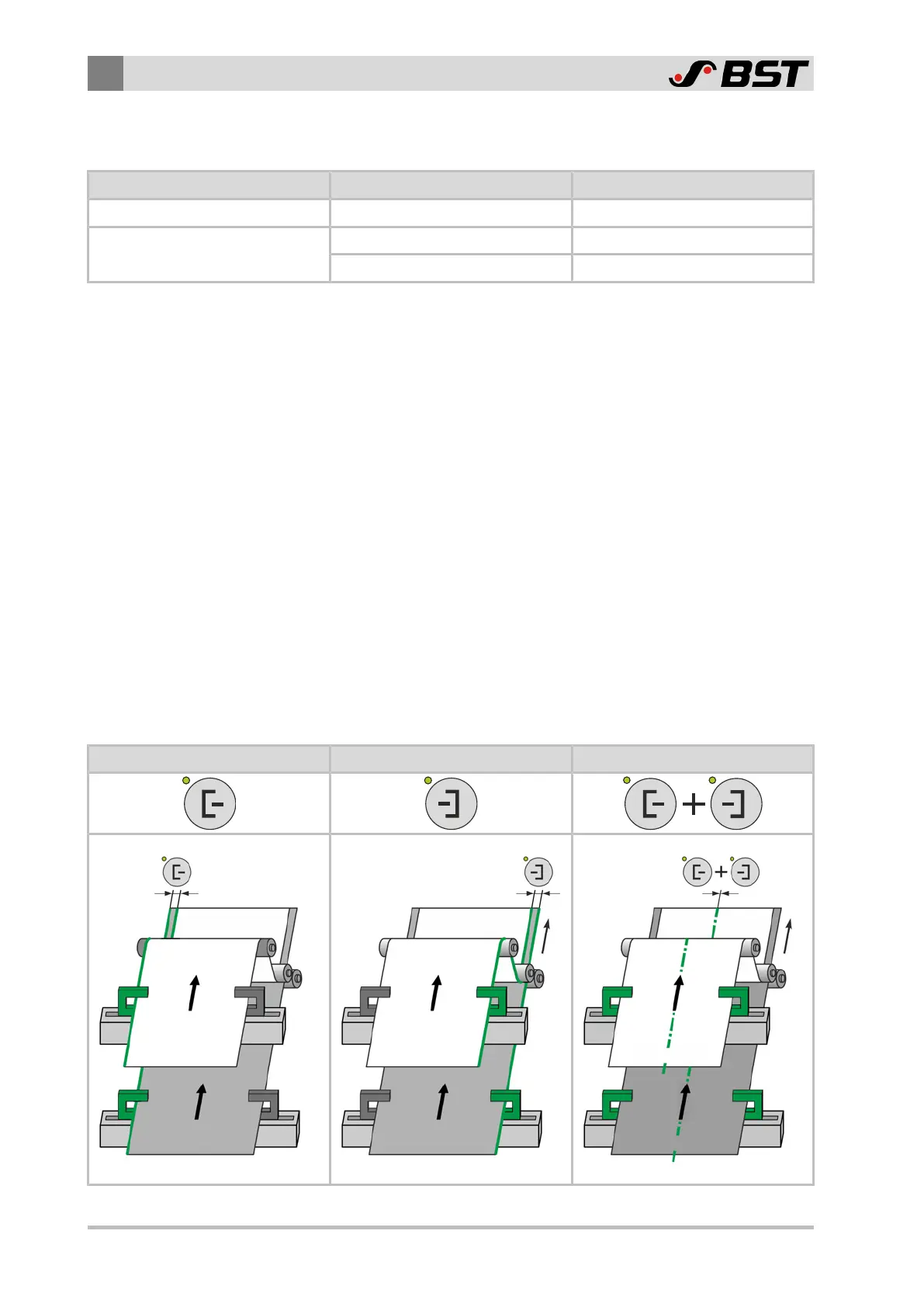

3.2 Guiding Modes

For the laminating process the Master-Save Guiding with Sensor

Positioner permits the following guiding modes.

Guiding to the left web edge Guiding to the right web edge Web center-line guiding

Loading...

Loading...