21

Installation

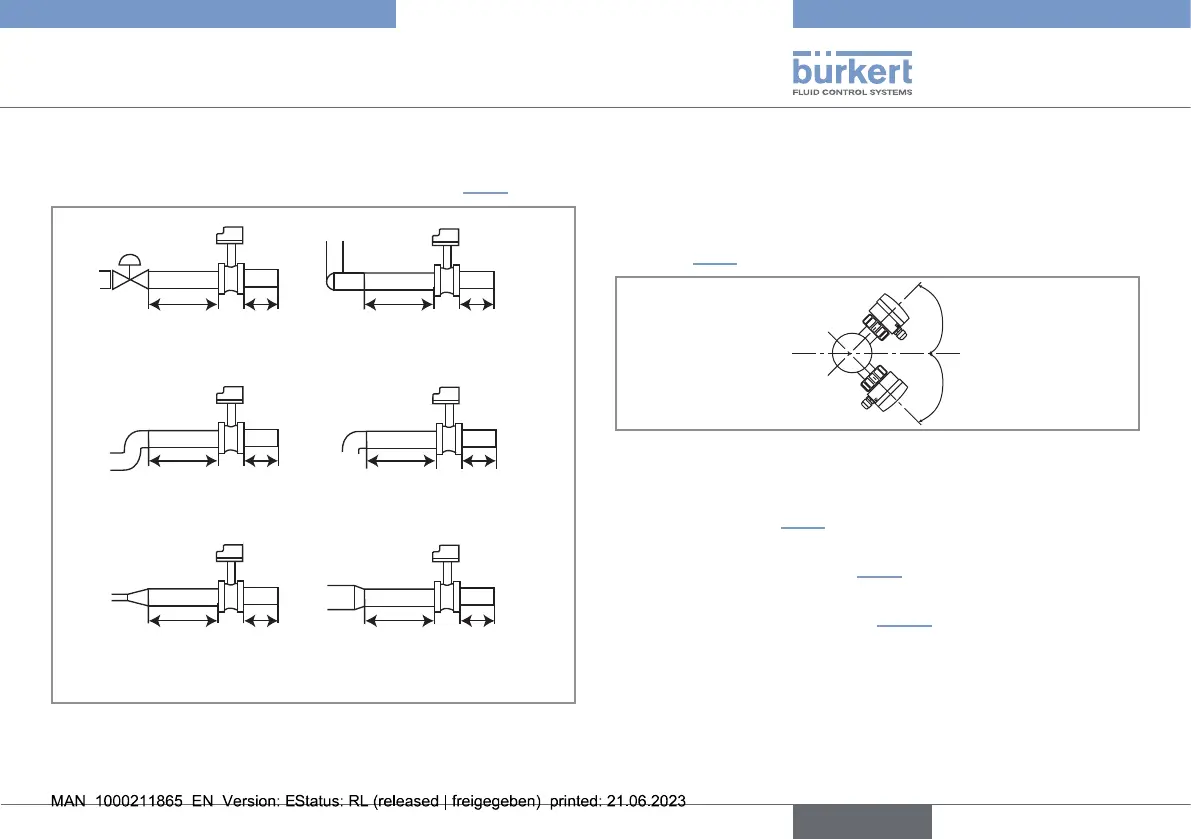

→ Install the device on the pipe to have the upstream and

downstream distances respected according to the design of

the pipes, refer to standard ENISO5167-1 and Fig.7:

50 x DN 5 x DN

40 x DN 5 x DN

25 x DN 5 x DN 20 x DN

18 x DN 5 x DN 15 x DN 5 x DN

With control valve

Pipe with 2 elbows at 90°

in 3 dimensions

Pipe with 2 elbows at 90° Pipe with 1 elbow at 90° or

1 T-piece

With pipe expansion With pipe reduction

Fig.7:

Upstreamanddownstreamdistancesdependingonthe

designofthepipes.

→ Respect the following additional mounting conditions to

ensure that the measuring device operates correctly:

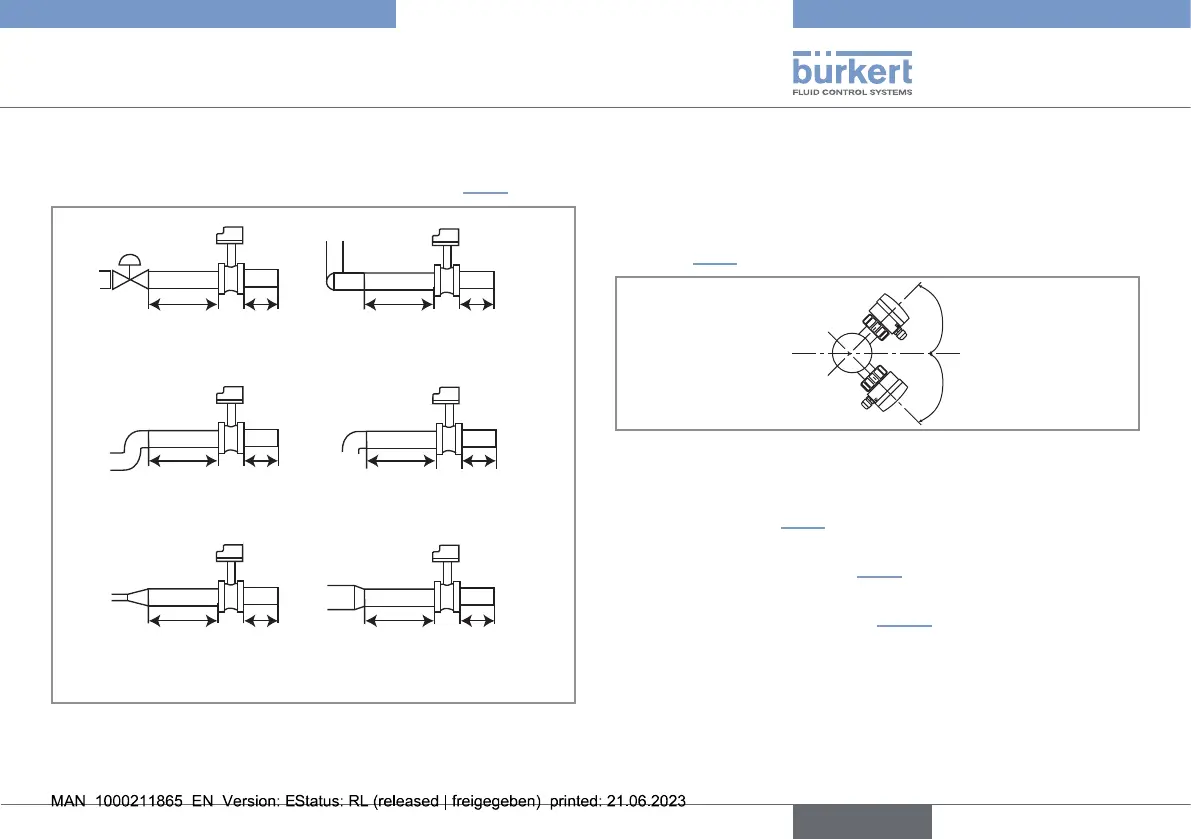

- We recommend to install the device at a 45° angle to the

horizontal centre of the pipe to prevent deposits on the

electrodes and false measurements due to air bubbles

(seeFig.8);

45°

45°

Fig.8: Mountingangleonthepipe

- Ensure that the pipe is always lled in the section around

the device (see Fig.9).

- When mounting vertically ensure that the ow direction is in

an upward direction (see Fig.9).

- Prevent the formation of air bubbles in the pipe in the sec-

tion around the device (see Fig.10).

- Always mount the device upstream a possible injection

point in the pipe of a high-conductivity uid (for example:

acid, base, saline, ...).

english

Type 8041

Loading...

Loading...