36

Adjustment and commissioning

Filter Position of switch3

slow

(Response time 10...90%=14s)

OFF

fast

(Response time 10...90%=5s)

ON

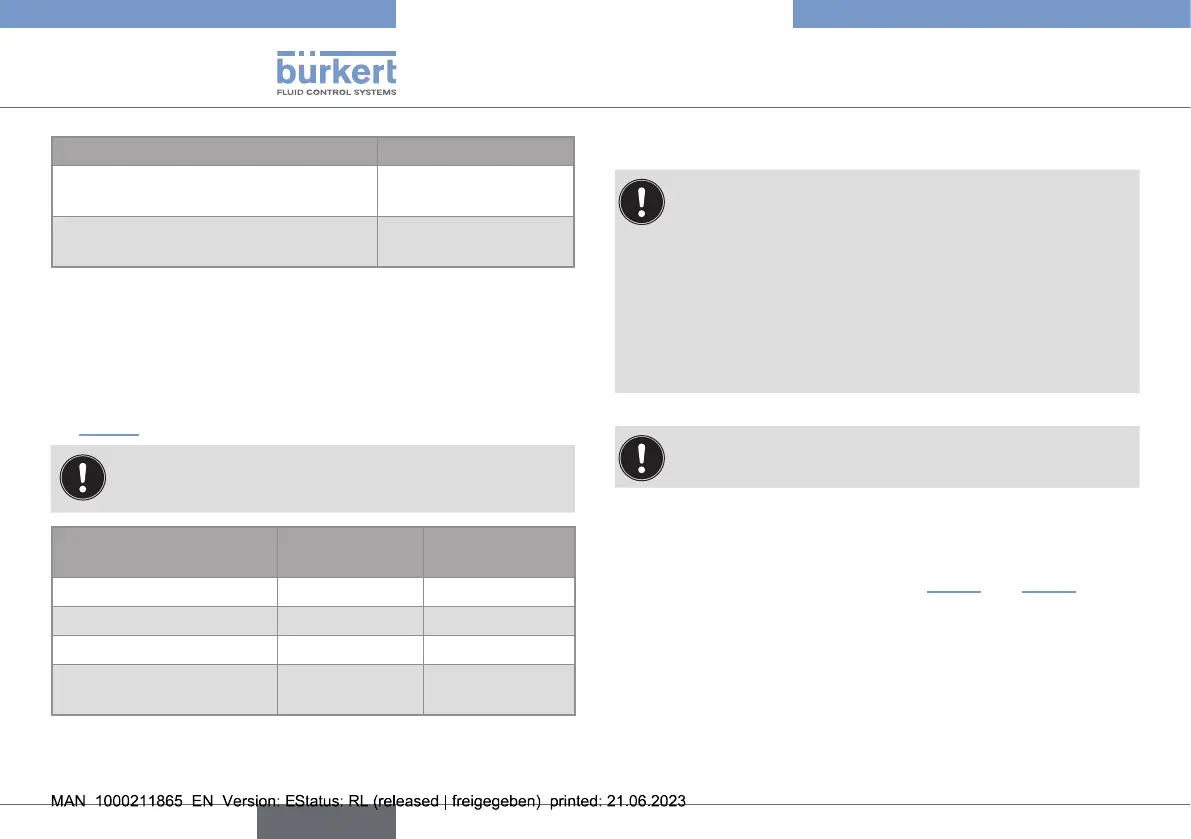

9.6. Selecting the measurement range

The output signal is proportional to the measured ow velocity.

Switches 4 and 5 are used to adjust the measuring range of the

device to your application.

→ Position switches 4 and 5 to select the measuring range (see

Fig.25, and the following table).

After the measuring range has been modied, the per-

centages set for the low and high switching thresholds

are applied to the new full scale selected.

Measuring range Position of

switch4

Position of

switch5

0...2m/s ON OFF

0...5m/s OFF ON

0...10m/s OFF OFF

0 to calibrated full scale

(between 2...10m/s)

ON ON

9.7. Calibrating the ow zero point

→ Calibrate the device on commissioning and after each

maintenance task.

Before calibrating the zero point on commissioning:

immerse the measuring element in the uid for 24h

before calibration.

• Before calibrating the zero point after each maintenance

task:

immerse the measuring element in the uid for 1h

before calibration.

→ Before calibration, ensure that the pipe does not

contain any air bubbles and that the uid is not

→ Fill the pipe with uid.

→ Stop the ow.

→ Calibrate the "zero ow" point (see Fig.27 and Fig.28).

english

Type 8041

Loading...

Loading...