51

Wiring the Lead Lag Setup

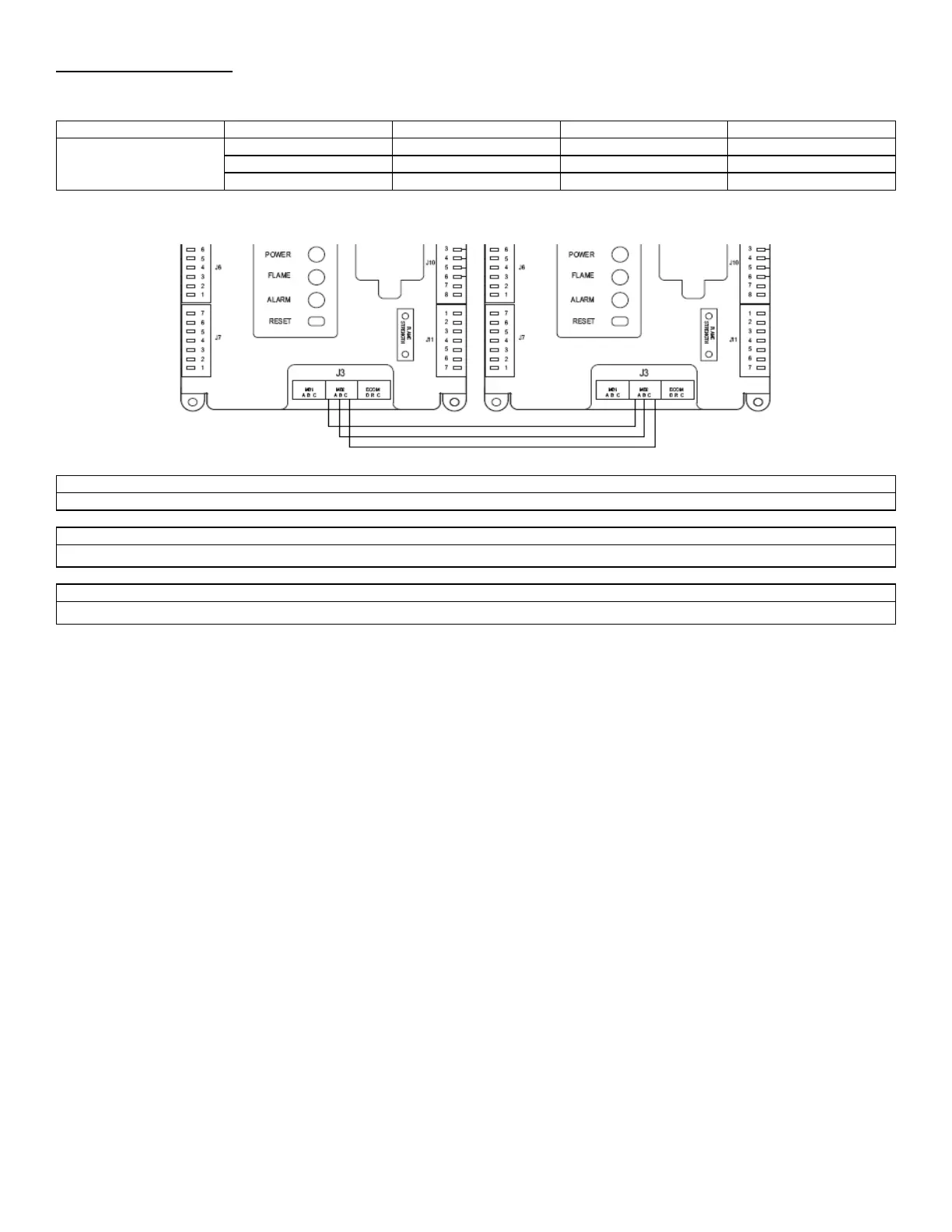

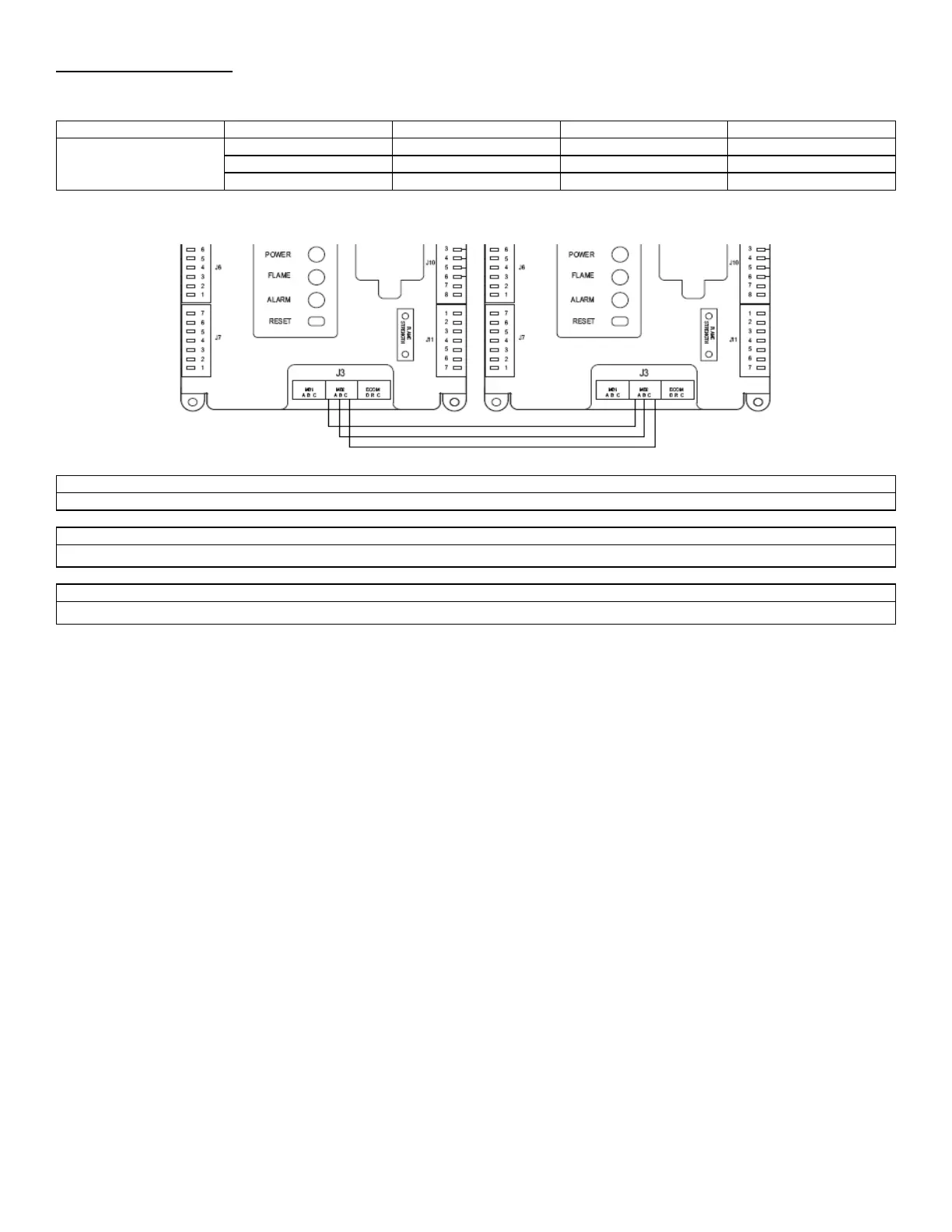

Use Cascade terminals in the juntion box to wire lead lag appliances.

J3, MB2

Figure 31: Lead Lag Wiring Setup (Left: Master, Right: Slave)

Recycle power on all boilers after programming is complete if lag boilers are not discovered automatically

CH Setpoint or DHW Setpoint must match Setpoint located in Lead Lag Master Configuration, for the system to operate correctly.

The Local/Remote switch must be set in the “Local” position on ALL lag boilers.

6.4 LOCAL/REMOTE SWITCH

The local remote switch mounted inside the control box is designed to deliver an enable signal either relying on an external contact

closure (Remote) or enabling the boiler locally (Local). When Remote is selected via the DPDT switch, the Remote Operator contacts

must close to deliver an enable signal. When Local is selected via the DPDT switch, a constant enable signal is present. When

troubleshooting the Avenger, it is recommended to switch to Local mode.

6.5 MODBUS, BACNET IP, BACNET MSTP, LONWORKS, METASYSN2 INTEGRATION

For detailed instructions on interfacing with Modbus/Bacnet/LonWorks/Metasys N2 Network, refer to Camus Hydronics website.

Loading...

Loading...