5

5

5-2

5-2

Adjustment > Outline > Image position adjustment

Adjustment > Outline > Image position adjustment

Outline

Adjustment when replacing parts

This section describes adjustment required in eld service works when replacing parts.

The parts are classied by function into the following 3 blocks.

Category

Replacing parts Reference

Scanning

System

CCD unit

“Action to Take after Replacing the CCD Unit”(page 5-3).

Copyboard glass

“Action to Take after Replacing the Platen Glass”(page 5-4).

ADF reading glass

“Action to Take after Replacing the ADF Scan Glass”(page

5-4).

Controller

System

Main controller PCB

“Action to Take after Replacing theMain Controller

PCB”(page 5-5).

DC controller PCB

“Action to Take when Replacing the DC Controller

PCB”(page 5-5).

RAM PCB

“Action to Take after Replacing the RAM”(page 5-5).

Laser Exposure

System

Laser scanner unit

”Action to Take after Replacing the Laser Scanner

Unit”(page 5-5).

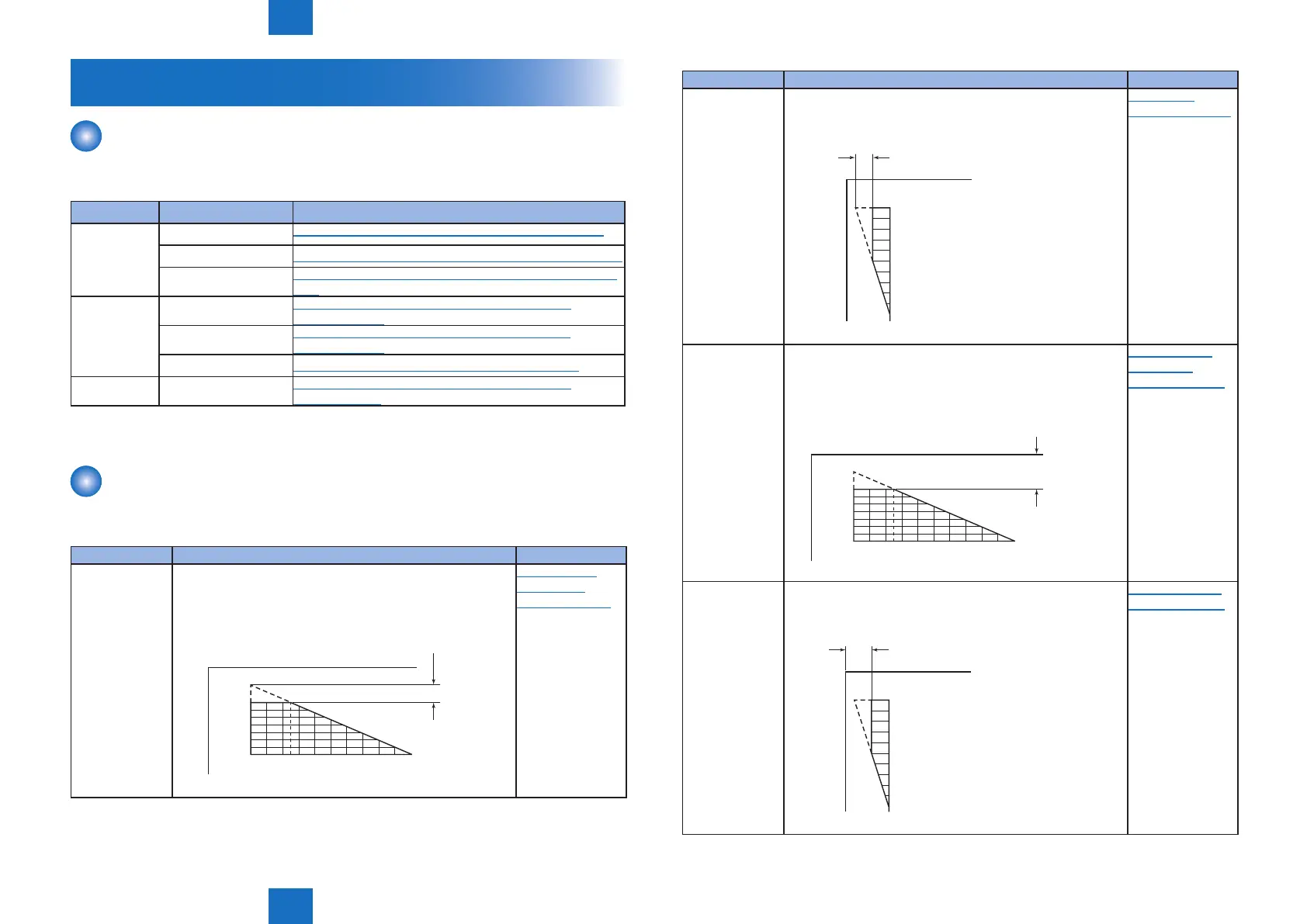

Image position adjustment

This section describes procedures when adjusting basic image position (image margins,

nonimage area, etc).

Category Item Reference

Margin Along the

Leading Edge

Single-sided copy: 2.5 ± 1.5 (mm)

Double-sided copy: 2.5 ± 2.0 (mm)

2 54 6 8 10 12 14 16 18 200

2.5+/-1.5mm

(2nd side of double-sided copy

: 2.5+/-2.0mm)

“Margin Along

the Leading

Edge”(page 5-6).

T-5-1

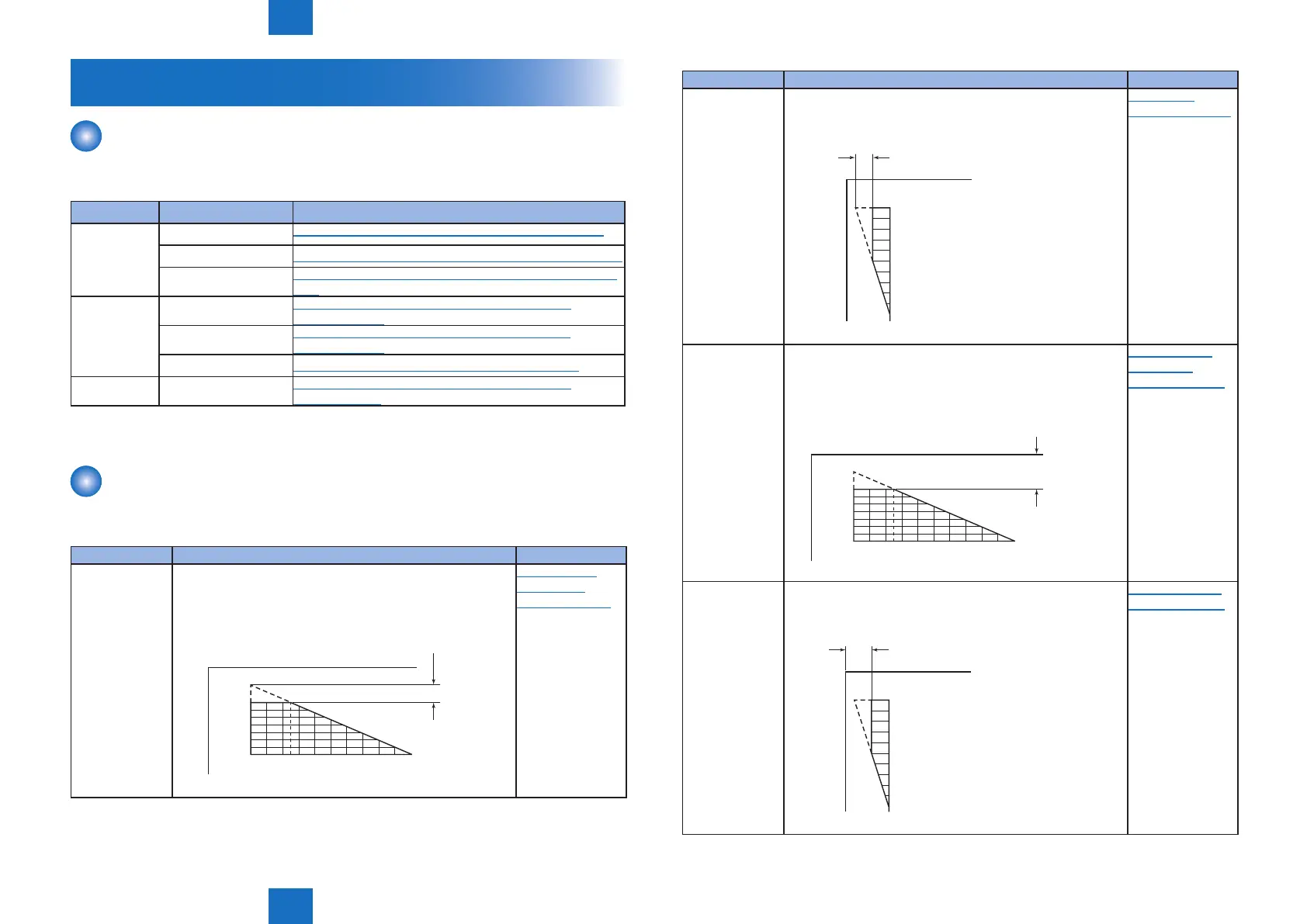

Category Item Reference

Left Image MarginSingle-sided copy: 2.5 ± 1.5 (mm)

Double-sided copy: 2.5 ± 2.0 (mm)

10

8

6

5

4

2

0

2.5+/-1.5mm

(2nd side of double-sided copy:

2.5+/-2.0mm)

“Left Image

Margin”(page 5-6).

Leading Edge

Non-Image Width

Single-sided copy: 2.5 ± 1.5 (mm)

Double-sided copy: 2.5 ± 1.5 (mm)

2 54 6 8 10 12 14 16 18 200

2.5+/-1.5mm

(2nd side of double-sided copy:

2.5+/-1.5mm)

“Leading Edge

Non-Image

Width”(page 5-6).

Left Non-Image

Width

Single-sided copy: 2.5 ± 1.5 (mm)

Double-sided copy: 2.5 ± 1.5 (mm)

10

8

6

5

4

2

0

2.5+/-1.5mm

(2nd side of double-sided copy:

2.5+/-1.5mm)

”Left Non-Image

Width”(page 5-7).

T-5-2

Loading...

Loading...