2

2

2-49

2-49

Technology > Fixing System > Controls > Down sequence control

Technology > Fixing System > Controls > Down sequence control

Related Service Mode

Offset of xing control temperature (High and low of control temperature)

PRINT > SW

> 62 (Control temperature during cassette feeding)

> 63 (Control temperature in Heavy/Heavy-H/Bond paper modes)

> 166 (Control temperature during manual feeding)

> 173 (Control temperature for the second side of 2-sided copying)

> 179 (Control temperature in Postcard/S-Postcard/Envelope modes)

<Setting value>

0 to 2: +15 deg C

3 to 11: +12 to -15 deg C (each 3 deg C) [Default: 7]

12 to 14: -15 deg C

■

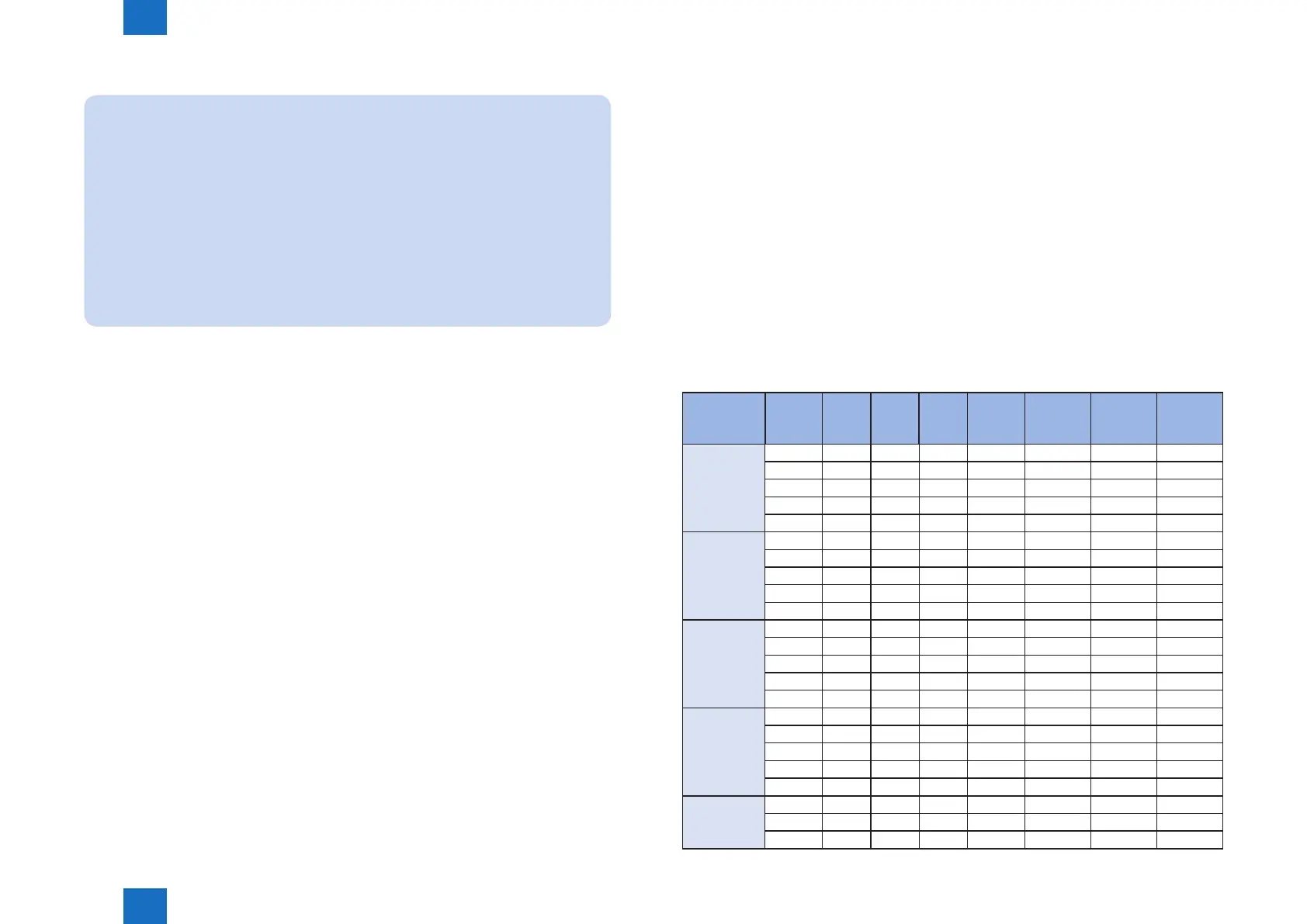

Down sequence control

●

Down sequence when feeding small size paper

Purpose:

To prevent temperature rise of non-feeding area in the case of continuous print of

small size paper (less than A4 of length in width direction), xing offset or deterioration

of xing lm.

Starting conditions:

When the detected temperature of sub thermistor (front) or (rear) reaches 255 deg C

or higher for 400 msec continuously.

Operation:

Temperature is reduced by making wider sheet-to-sheet distance with the maximum 4

steps to control the temperature at lower than the target temperature for normal print.

Fixing mode Step

B4

LGL

B5

EXE

A4R

LTRR

A5R

B5R

EXE-R

Free size Postcard Envelope

Plain paper

Thin paper

S-thin paper

Normal 26 45 32 20 13 --- ---

1 20 20 20 18 8 --- ---

2 12 12 12 14 8 --- ---

3 10 10 10 14 8 --- ---

4 8 8 8 14 8 --- ---

Heavy paper

Normal 17 30 21 17 13 --- ---

1 12 20 20 14 8 --- ---

2 10 12 12 14 8 --- ---

3 8 10 10 14 8 --- ---

4 8 8 8 14 8 --- ---

Heavy-H

paper

Normal 17 25 17 17 13 --- ---

1 12 20 12 14 8 --- ---

2 10 12 10 14 8 --- ---

3 8 10 8 14 8 --- ---

4 8 8 8 14 8 --- ---

Bond paper

OHP

Normal 13 25 14 17 13 --- ---

1 12 20 12 14 8 --- ---

2 10 12 10 14 8 --- ---

3 8 10 8 14 8 --- ---

4 8 8 8 14 8 --- ---

Postcard

Normal --- --- --- --- --- 18 ---

1 --- --- --- --- --- 14 ---

2 --- --- --- --- --- 10 ---

Loading...

Loading...