2

2

2-53

2-53

Technology > Fixing System > Controls > Paper loop amount control before xing

Technology > Fixing System > Controls > Paper loop amount control before xing

■

Paper loop amount control before xing

Purpose:

To get a proper image by avoiding a shock when the trailing edge of paper comes out

of the registration roles, an appropriate paper loop is formed between transfer roller

and xing roller.

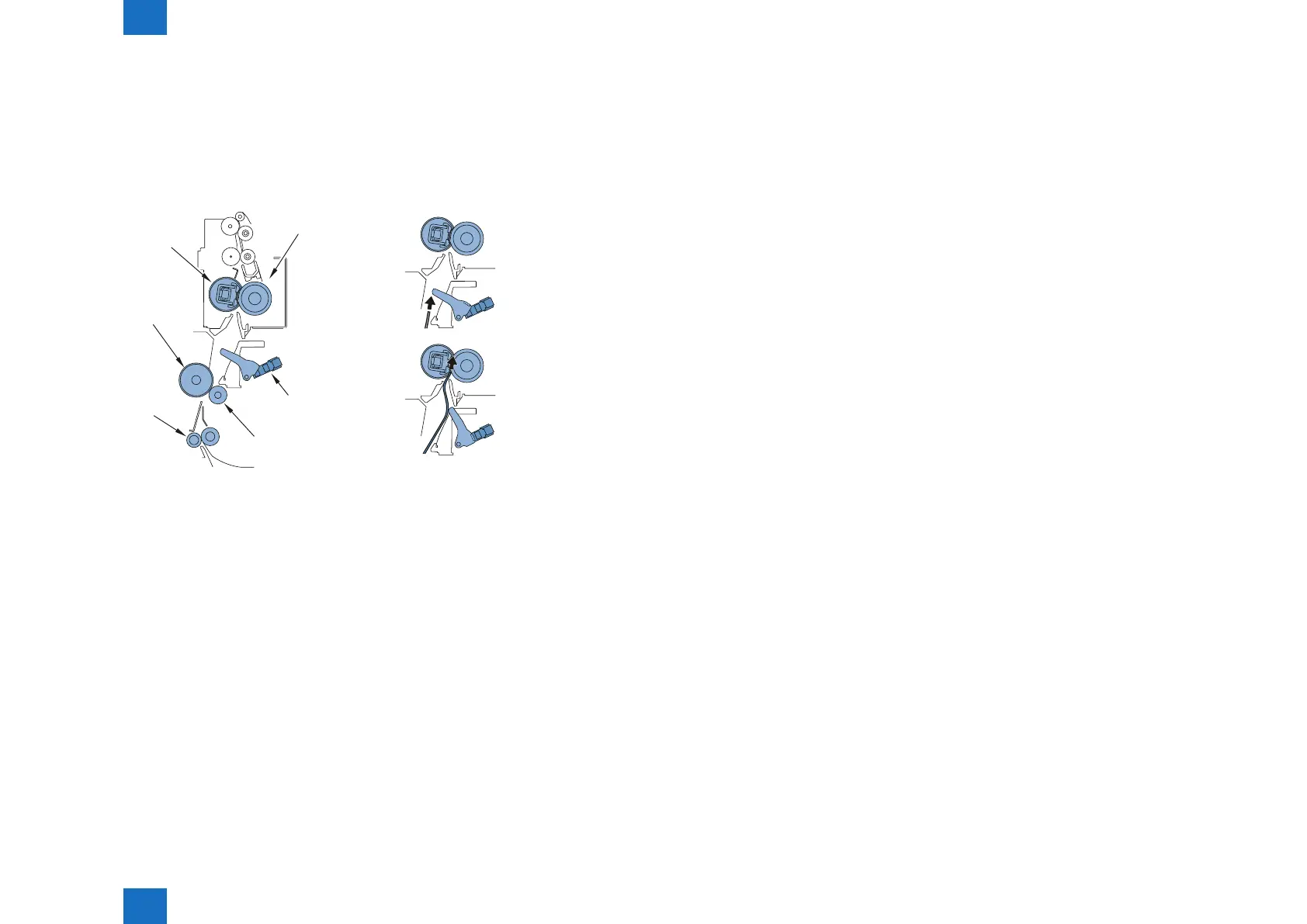

Pressure roller

Fixing film

Drum

Loop sensor(S6)

Transfer roller

Registration

roller

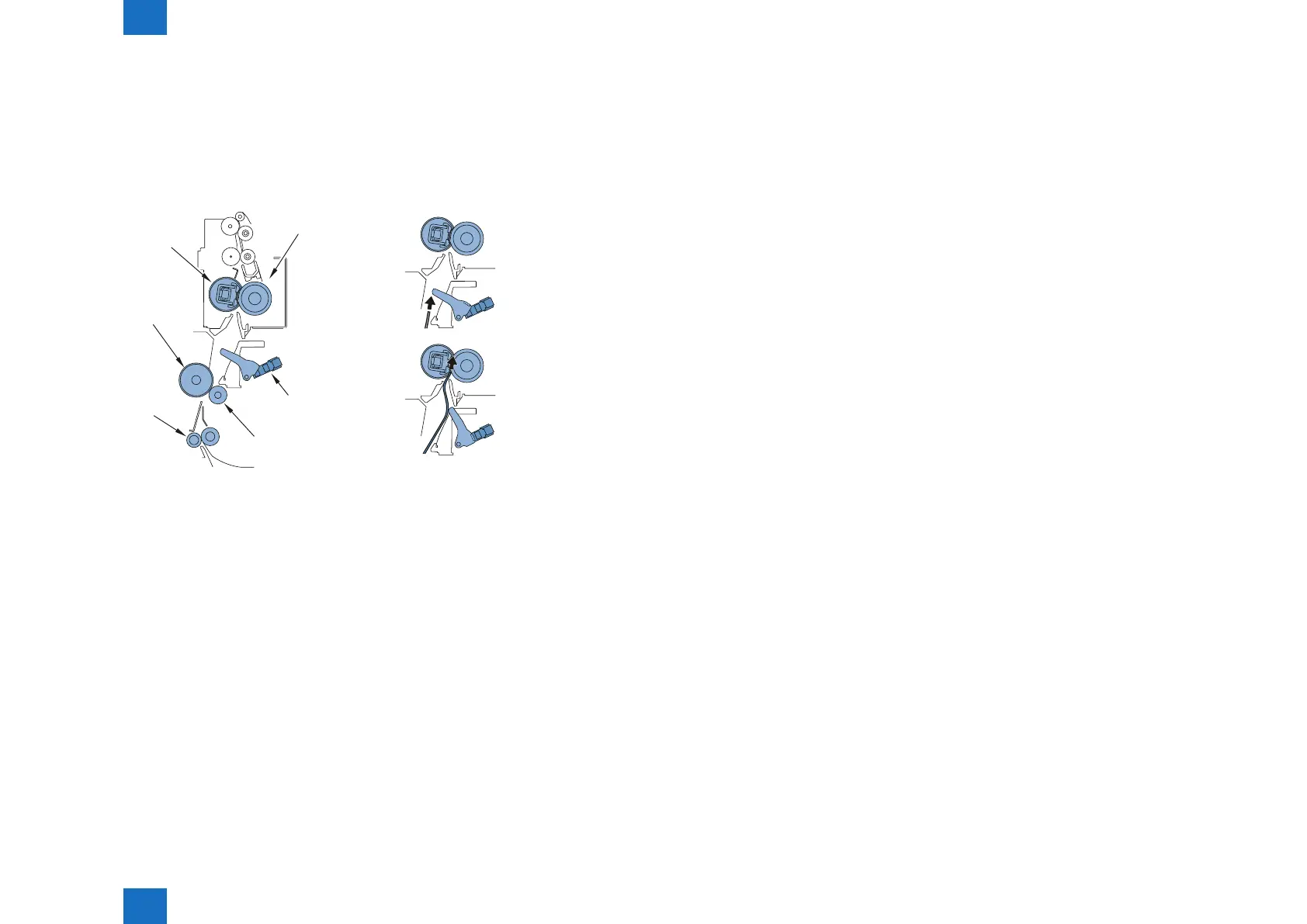

Sensor: OFF

Sensor: ON

Starting conditions:

This control is performed at every paper feeding.

Operation:

The xing motor drive speed is controlled as follows by detecting the paper loop

between transfer roller and xing roller with the loop sensor.

1) The xing motor drive speed is reduced by 3.1% when the reading edge of paper is

fed 35mm from the transfer roller. The reduced speed is kept until the loop sensor is

turned on by the formed paper loop.

2) After detecting the ON condition of the loop sensor for 50 msec continuously, the

xing motor drive speed is increased by 0.8% compared with the process speed. The

increased speed is kept until the loop sensor is turned off by the deleted paper loop.

3) After detecting the OFF condition of the loop sensor for 50 msec continuously, the

xing motor drive speed is reduced by 3.1% compared with the process speed. The

reduced speed is kept until the loop sensor is turned on by the formed paper loop.

F-2-77

4) Repeat steps 2) and 3). The xing motor drive speed is increased by 0.8%

compared with the process speed when the trailing edge of paper reaches 65 mm

before coming out of the registration roller.

5) When continuously making prints, return to step 1). When making a single print,

shift to the last rotation.

Loading...

Loading...