Installation

2-10

750-382

CBT

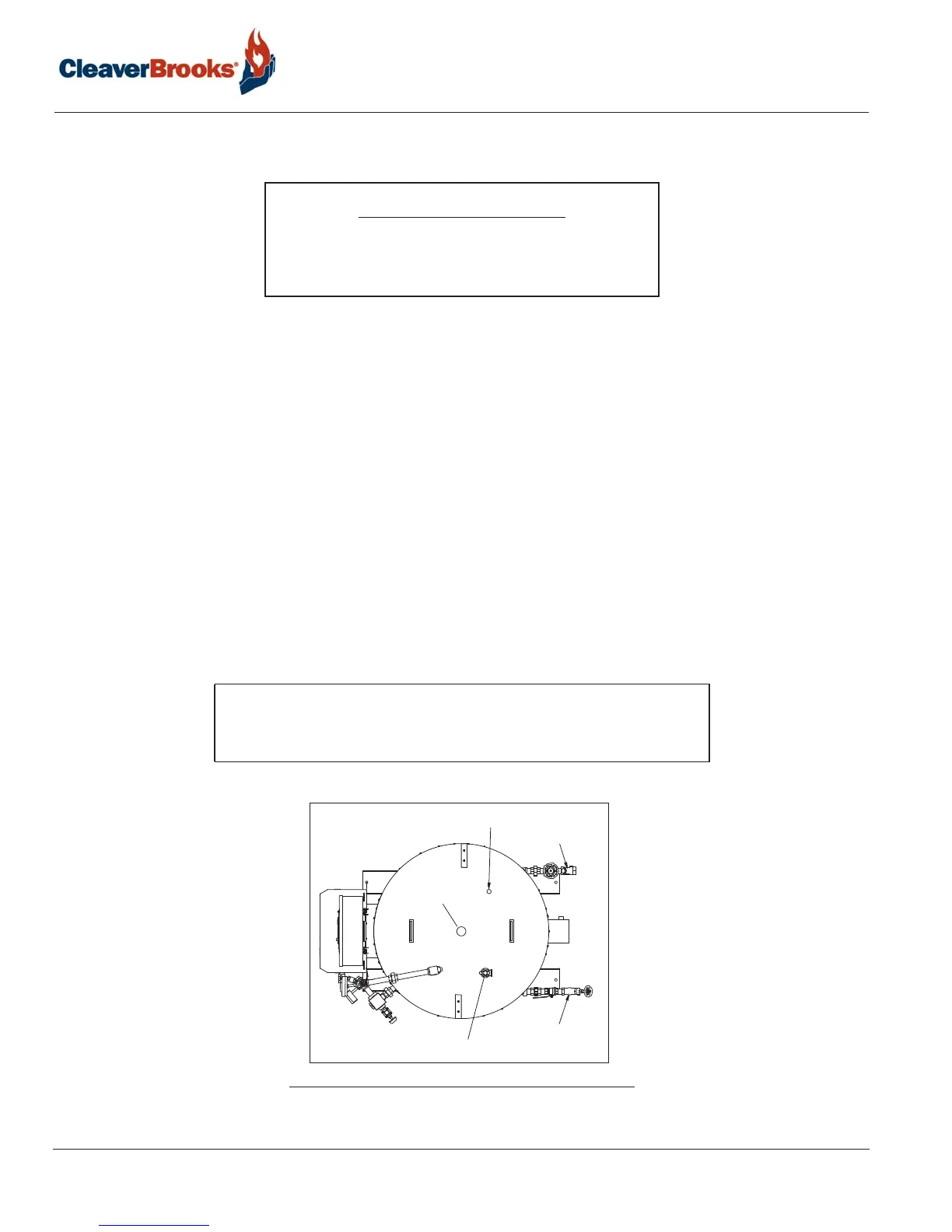

2.5 — Boiler Waterside Connections

A pressure relief valve (safety valve), provided with the boiler, must be installed in the mounting provided. Use

pipe sealing compound and a flat sided wrench when securing the safety relief valve. Do not use a pipe wrench

and do not over tighten the relief valve. The safety valve must be mounted in a vertical position so that discharge

piping and code-required drains can be properly piped to prevent buildup of back pressure and accumulation of

foreign material around the valve seat area. Apply only a moderate amount of pipe compound to male threads and

avoid over-tightening, which can distort the seats. Use only flat-jawed wrenches on the flats provided.

Connection to the main steam header is made at the nozzle projecting upward from the boiler shell. ASME code

requires a suitable stop valve to be installed between the boiler and main steam header if multiple boilers are tied

to the header. This valve should be as close as possible to the boiler to facilitate venting and pressure testing. A

suitably rated gate valve is recommended for this purpose.

Feedwater is introduced through the piping assembly installed on the side of the boiler vessel. A stop valve and

check valve are optional equipment.

The feedwater supply should provide sufficient pressure to meet minimum flow requirements.

Cleaver-Brooks offers bottom blowdown piping and valves for CBT boilers. Optional surface blowoff is also

available.

A qualified boiler and piping installer should make all boiler waterside connections.

Only properly certified personnel such as the safety valve

manufacturer’s certified representative can adjust or repair the

boiler safety valves. Failure to follow this warning could result in

serious personal injury or death.

Notice

Before filling boiler, check that all waterside

openings/fittings are plugged and all inspection

covers are secured

SURFACE BLOWOFF

FEEDWATER

BOTTOM

BLOWDOWN

STEAM

OUTLET

SAFETY VALVE

FIGURE 2-6. Waterside connections (boiler top view)

Loading...

Loading...