Installation

2-4

750-382

CBT

2.3 — Boiler Room

The boiler room must comply with all building codes and regulations. An adequate supply of combustion air and

sufficient ventilation are required for safe operation. If the optional direct vent combustion air kit is not used,

ventilation must be provided to meet applicable regulations for air supply.

Clean combustion air is required for optimum efficiency and boiler operation (minimum combustion air 10 cfm

per boiler horsepower). Dust and airborne contaminants will adversely effect burner performance. See Chapter 3,

Stack and Intake Venting, for more information.

If conditions dictate, a serviceable filter must be placed at the burner inlet to eliminate airborne contamination to

the burner. If a direct vent air intake is used, the intake and flue venting should be terminated so as to prevent

rain, snow, dust, or debris from entering the intake piping.

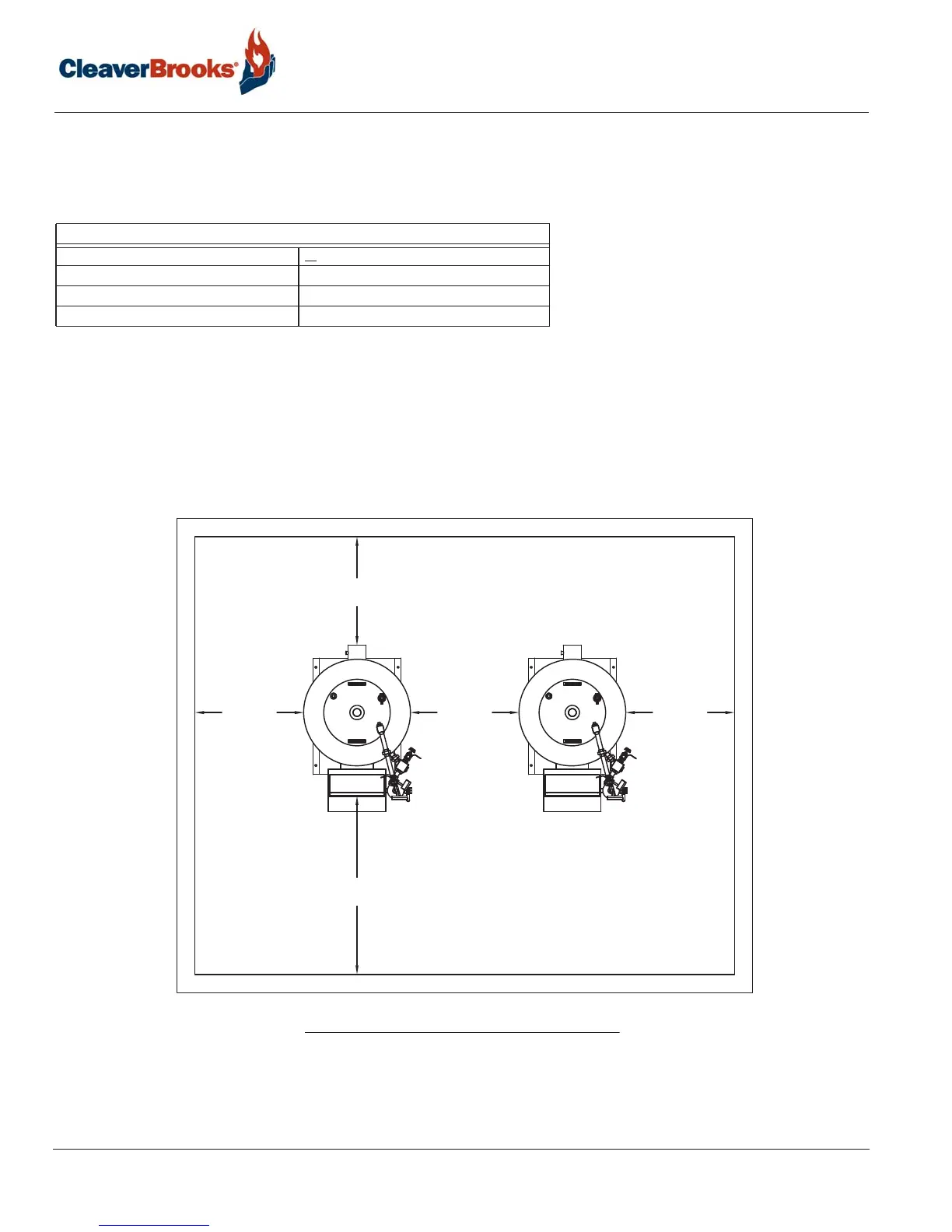

Observe proper clearances above and around boiler - see Figure 2-2.

TABLE 2- 2. Boiler room ambient conditions

Relative humidity < 85% non-condensing

Ambient temperature range 0

o

C to 50

o

C / 32

o

F to 122

o

F

Storage temperature range -40

o

C to 60

o

C / -40

o

F to 140

o

F

Combustion air temperature 0

o

C to 50

o

C / 32

o

F to 122

o

F

18”

18”

36”

18” 18”

IN FRONT OF

ELECTRICAL

CONTROL PANEL

CLEARANCE

ABOVE BOILER = 18”

FIGURE 2-2. Recommended Clearances

Loading...

Loading...