Maintenance

5-2

750-382

CBT

5.1 — General

A well-planned maintenance program will help avoid unnecessary downtime or costly repairs, and will promote

safety and aid boiler inspectors. It is recommended that a boiler room log or record be maintained. Recording of

daily, weekly, monthly, and yearly maintenance activities will help to obtain economical and lengthy service from

the equipment.

Only trained and authorized personnel should be permitted to operate, adjust, or repair the boiler and related

equipment. The boiler room should be kept free of all material and equipment not necessary to the operation of

the boiler or heating system.

Be alert to unusual noises, improper gauge readings, leaks, etc. Any leaks - fuel, water, steam, exhaust gas -

should be repaired promptly and with attention to safety. Preventive measures, such as regularly checking the

tightness of connections, should be included in regular maintenance activities.

Insurance regulations and local laws normally require periodic inspection of the pressure vessel by an authorized

inspector. Inspections are usually, though not necessarily, scheduled for periods of normal boiler downtime, such

as an off season. This period can be used to accomplish maintenance, replacement, or repairs that cannot easily

be done at other times.

NOTE: To insure proper operation, use only Cleaver-Brooks parts for replacement.

While the inspection pertains primarily to the waterside and fireside surfaces of the pressure vessel, the inspection

period provides operators with an opportunity for a detailed check of all boiler components including piping,

valves, gaskets, refractory, etc. Comprehensive cleaning, spot painting, and replacement of expendable items

should be planned for and taken care of during this time.

Cleaver-Brooks recommends common replacement parts be on hand during inspection and maintenance. Please

refer to the Recommended Spare Parts List In the Parts section of this manual.

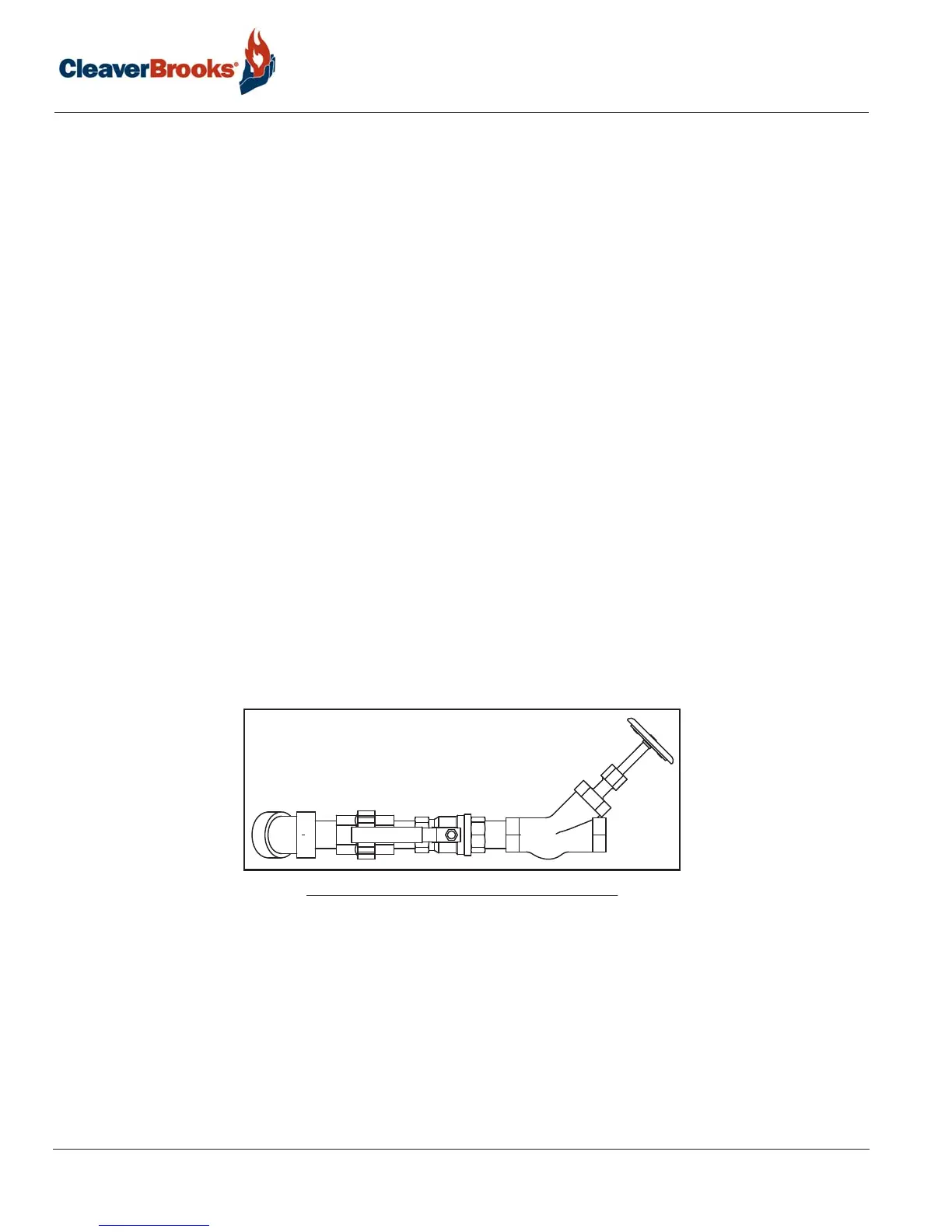

5.2 — Bottom blowdown

Water treatment alone can never completely eliminate unwanted solids from boiler feedwater. In order to keep

these substances to a minimum, blowdown should be performed at regular intervals.

If both a quick-opening and a slow-opening valve are present, the quick-opening valve (the valve nearest the

boiler) is opened first and closed last, with blowdown controlled using the slow-opening or downstream valve.

Bottom blowdown should be done under a light load and with the water level at the normal operating level.

Blowdown should be piped to a blowdown separator.

FIGURE 5-1. Bottom blowdown piping

Loading...

Loading...