750-382

CBT

5-11

Safety valve

5.8 — Safety valve

The safety valve is an important safety device and deserves attention accordingly. Follow the recommendations of

your boiler inspector regarding valve inspection and testing. The frequency of testing, either by use of the lifting

lever or by raising the steam pressure, should be based on the recommendation of your boiler inspector and/or the

valve manufacturer, and should be in accordance with Sections VI and VII of the ASME Boiler and Pressure Vessel

Code.

Avoid excessive operation of the safety valve; a valve that is opened too frequently can develop leaks. Safety valves

should be operated only often enough to assure that they are in good working order. When a pop test is required,

raise the operating pressure to the set pressure of the valve, allowing it to open and reseat as it would in normal

service.

Do not hand operate the valve with less than 75% of the stamped set pressure on the underside of the disc. When

hand operating, be sure to hold the valve in an open position long enough to purge accumulated foreign material

from the seat area and then allow the valve to snap shut.

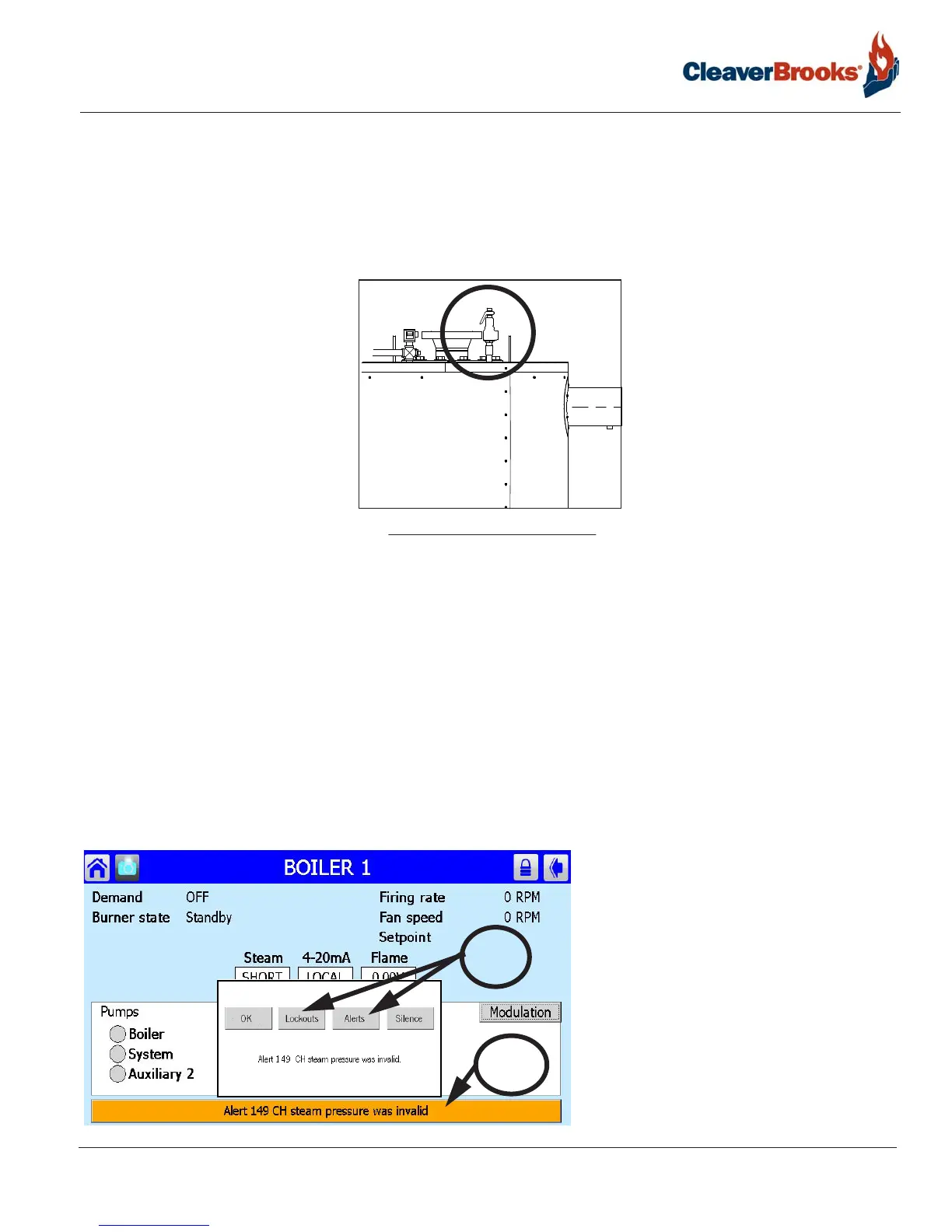

5.9 — Troubleshooting

The Falcon lockout and alert histories (full modulation units) contain information which can help in determining

the cause of problems. To view the lockout/alert history, first press the alarm banner, then press the appropriate

button in the pop-up window.

FIGURE 5-11. Safety valve

Alarm

banner

View

history

Loading...

Loading...