Introduction

1-4

750-382

CBT

1.2 — Burner

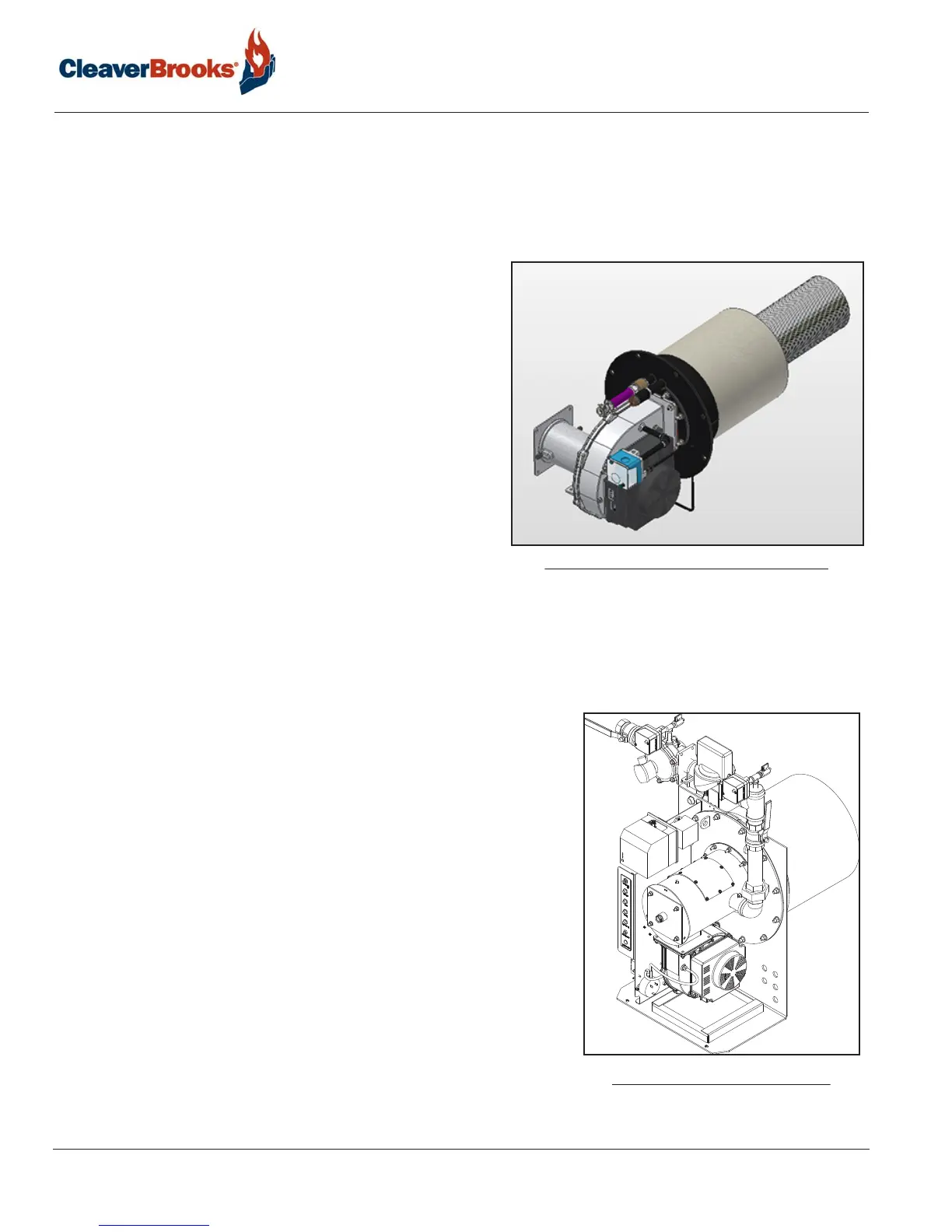

1.2.1 — Full modulation (CBT-M)

Full modulation units use a premix burner with a self-regulat-

ing gas valve-venturi system, ECM variable regulating gas

valve, variable speed blower, and Fecralloy metal fiber

burner canister.

• Full modulation is provided using the integral variable

speed combustion air fan and Falcon control.

• The low temperature, surface combustion burner flame

provides low emissions and optimum combustion effi-

ciency.

• Direct spark ignition with UV flame detection.

• At maximum firing rate, the sound level of the burner is

less than 70 dBA, measured in front of the boiler at a dis-

tance of 3 feet. At reduced firing rates, sound levels are

even lower.

• Provision is made for optional direct vent combustion air

connection.

• Combustion Air Proving Switch standard.

• Combustion air filter is standard.

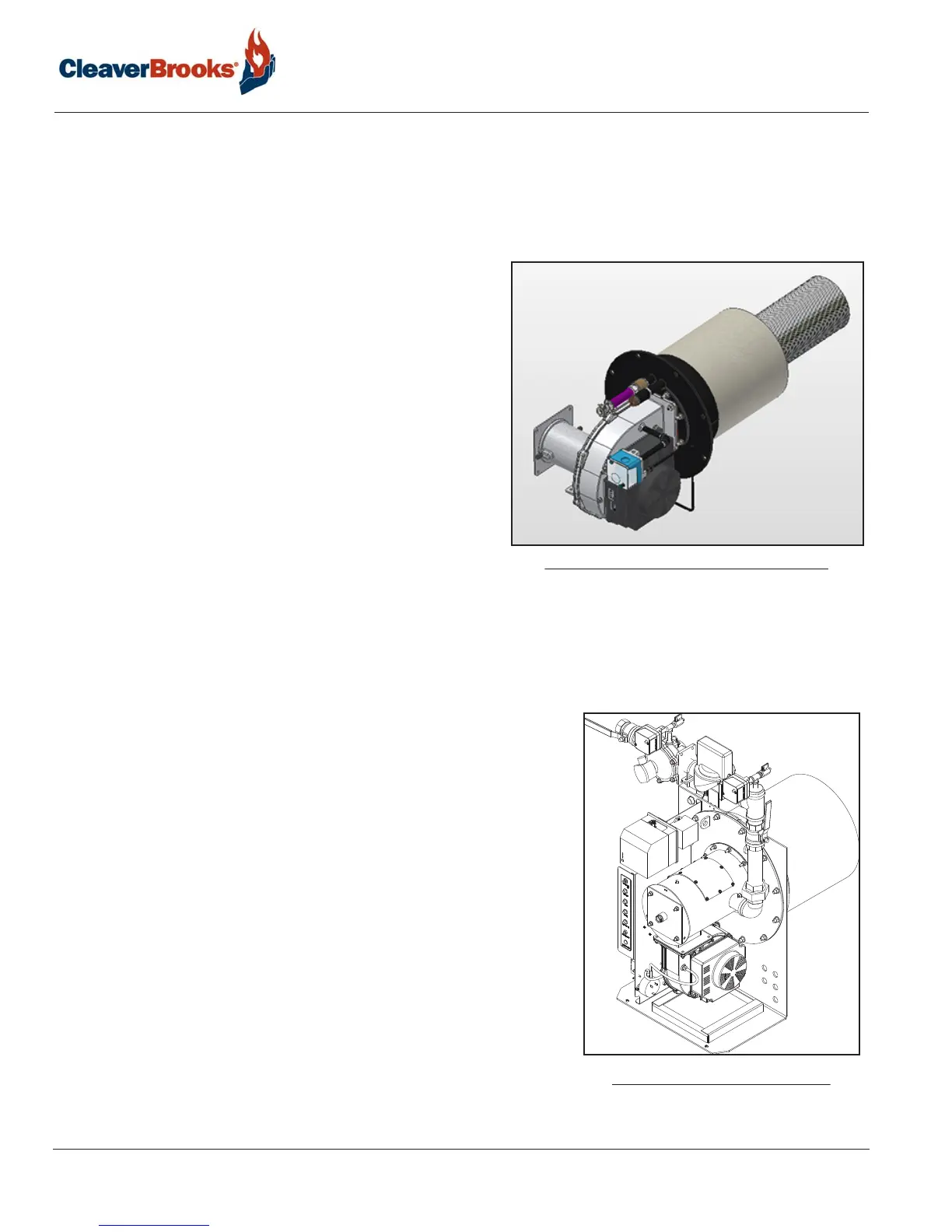

1.2.2 — On-off firing (CBT)

Gas is introduced into the combustion zone from a circular manifold

through multiple ports in the manifold. Burner firing is regulated by a

main gas regulator operating steam pressure control. Burner includes

microprocessor-based flame supervision control.

• Direct spark ignition with flame rod.

• Provision is made for optional direct vent combustion air connec-

tion.

• Combustion Air Proving Switch standard.

• Combustion air filter is standard.

FIGURE 1-3. Full modulation burner

FIGURE 1-4. On/off burner

Loading...

Loading...