Introduction

1-2

750-382

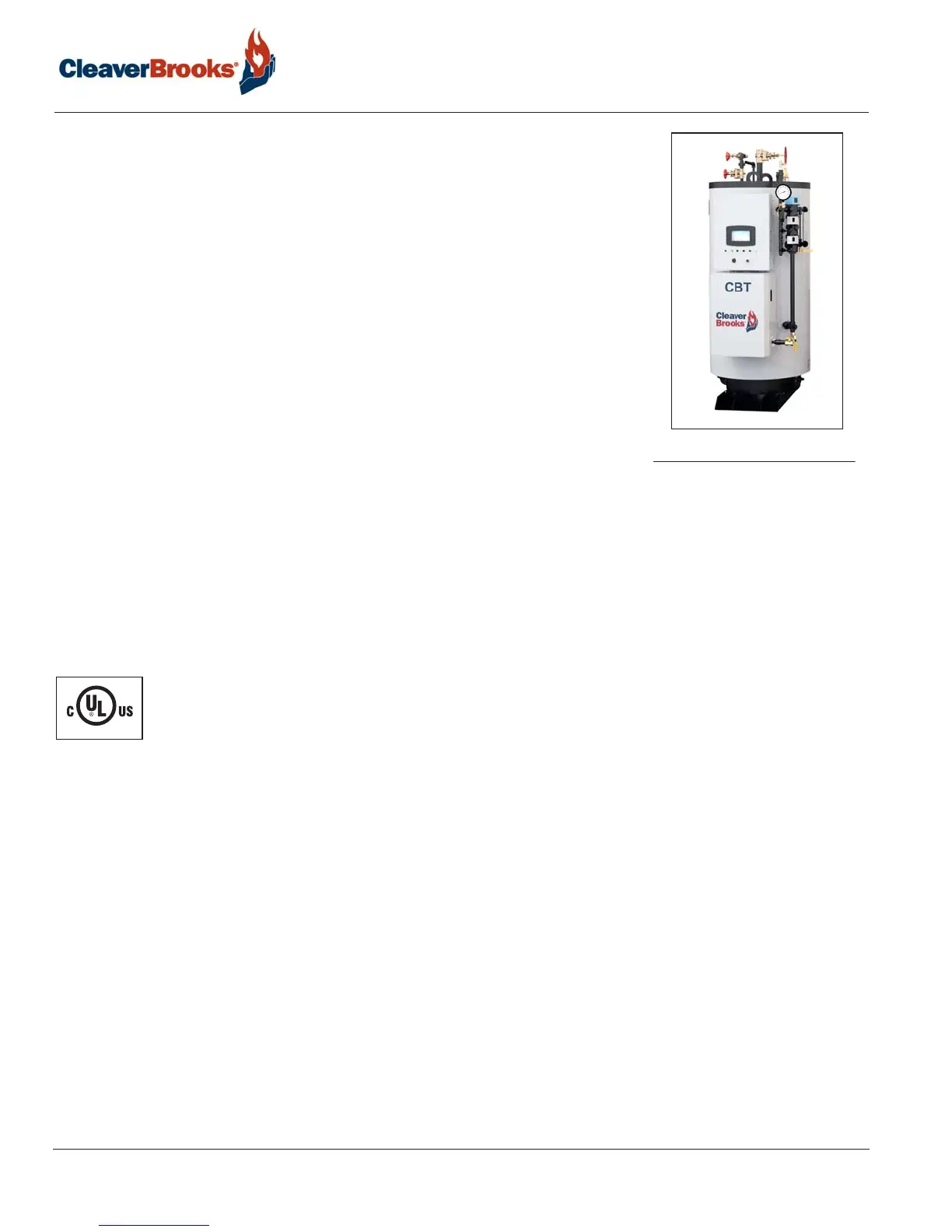

CBT

The Cleaver-Brooks Model CBT is a two-pass vertical tubeless steam boiler with

side-mounted burner.

The CBT features thick pressure vessel plates designed to provide long life.

Full modulation and on/off options are available. On full modulation units, an

ECM variable speed combustion air blower modulates the burner to precisely

match steam production to demand for reduced fuel usage and cycling. The

side-mount burner arrangement allows for a larger steam space to deliver excep-

tionally dry steam quality while allowing easy access for service and mainte-

nance. The Falcon control keeps the boiler and burner consistently operating at

peak efficiency.

On/off burners use the CB780 burner management control.

The CBT is available in 10, 15, 20, 25, and 30 HP sizes. Features include:

• Natural gas and propane fuels

• 15 psig or 150 psig design pressure

• Up to 84% efficiency and high turndown with the PID modulating premix

burner.

• Low emissions: less than 20 ppm NOx (full mod, natural gas only)

• Robust pressure vessel, designed to provide long life; 5 year pressure vessel warranty

• Standard integrated control with user-friendly interface for peak operation and efficiency

Quality construction

ASME construction ensures high quality design, safety, and reliability.

UL listed

The Model CBT and CBT-M are UL listed for both the US and Canada.

Premix technology

The Model CBT-M Boiler utilizes “Premix” technology to mix both fuel and combustion air prior to entering the

firing chamber. This technology provides clean, efficient combustion with very low emission levels.

1.1 — Pressure vessel

The boilers are constructed in accordance with the ASME Boiler Construction Code, Section I for high pressure

steam boilers and Section IV for low pressure steam boilers. High pressure steam boilers are stamped with the

ASME “S” symbol. Low pressure steam boilers are stamped with the ASME “H” symbol. The ASME data plate

can be found on the lower portion of the vessel on the front or left side (see Figure 1-2).

The CBT is a vertically oriented 2-pass tubeless pressure vessel design with a water-backed furnace. The first

fireside pass utilizes radiant heat transfer and the second pass uses convection. The second pass flue passage-

ways incorporate extended heating surfaces designed using computational fluid dynamics (CFD) modeling.

The large steam chest volume ensures exceptional dry quality steam at both high and low operating pressures.

FIGURE 1-1. CBT-M boiler

Loading...

Loading...