750-382

CBT

5-7

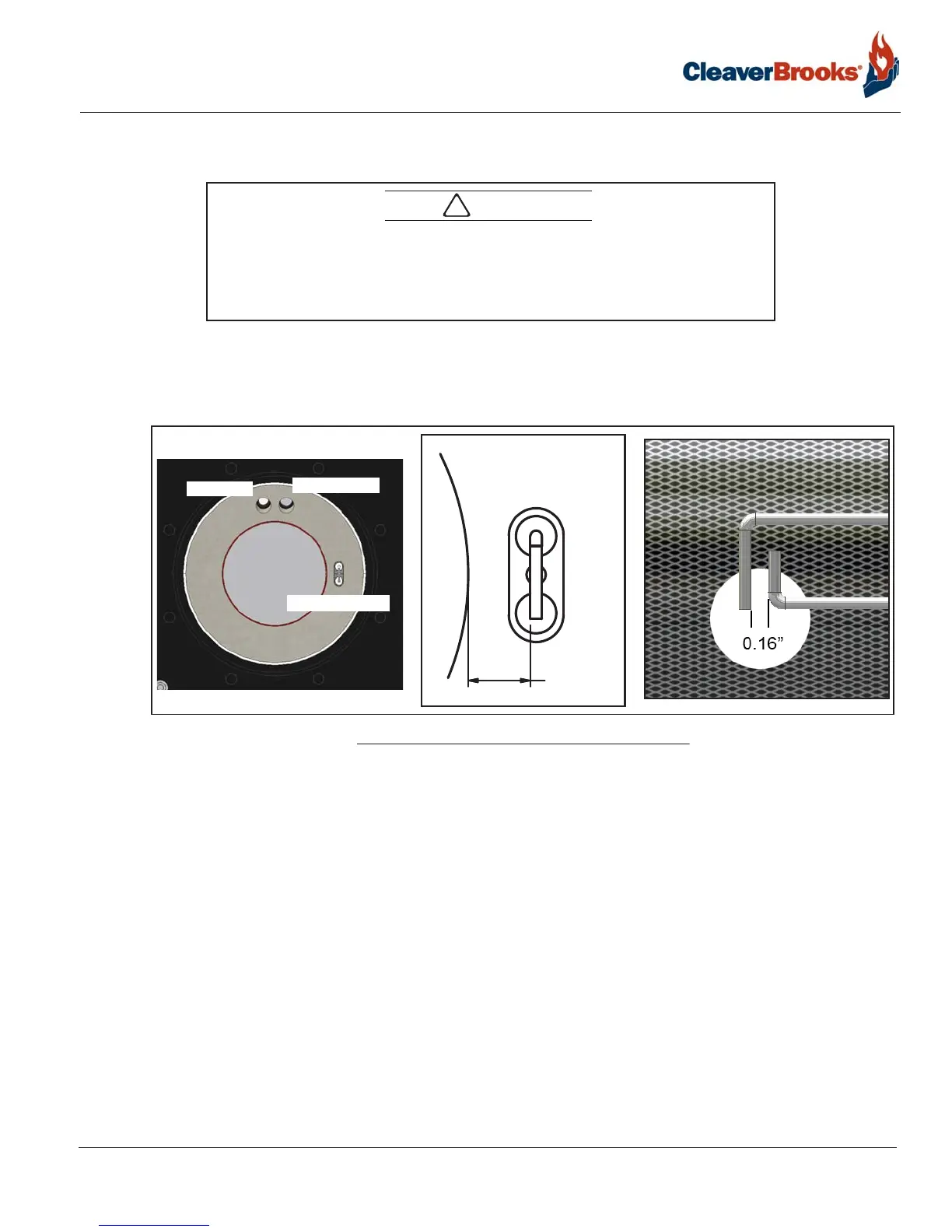

Ignition electrode

5.5 — Ignition electrode

5.5.1 — Full modulation burners

The ignition electrode should be checked on an annual basis or as needed if ignition problems are encountered.

In order to verify spacing of electrode, center the burner cylinder within the dry oven. Then attach electrode to

the dry oven with the screws provided. Verify the dimensions shown in Figure 5-5.

5.5.2 — On/off burners

The ignition transformer requires little attention other than making sure the ignition wire is firmly attached to the

transformer and the electrode. Be sure the wire insulation is in good condition and not grounded. Failure to keep

the ignition electrode clean and properly set can cause faulty operation. The electrode assembly is supported by

a socket in the diffuser and gas inlet tube. No adjustment is required except proper positioning of the electrode

wire.

!

Caution

The dimensions on the Ignition Electrode are not easily adjustable.

Bending the rods can cause damage to the insulating material. In addition, a bent

electrode will have a tendency to return to its original shape when heated. If the

electrode is out of specification, replacement is generally recommended.

0.64 GAP

FIGURE 5-5. Igniter, full modulation burner

Flame scanner

Sight glass

Ignition electrode

Loading...

Loading...