Commissioning

4-24

750-382

CBT

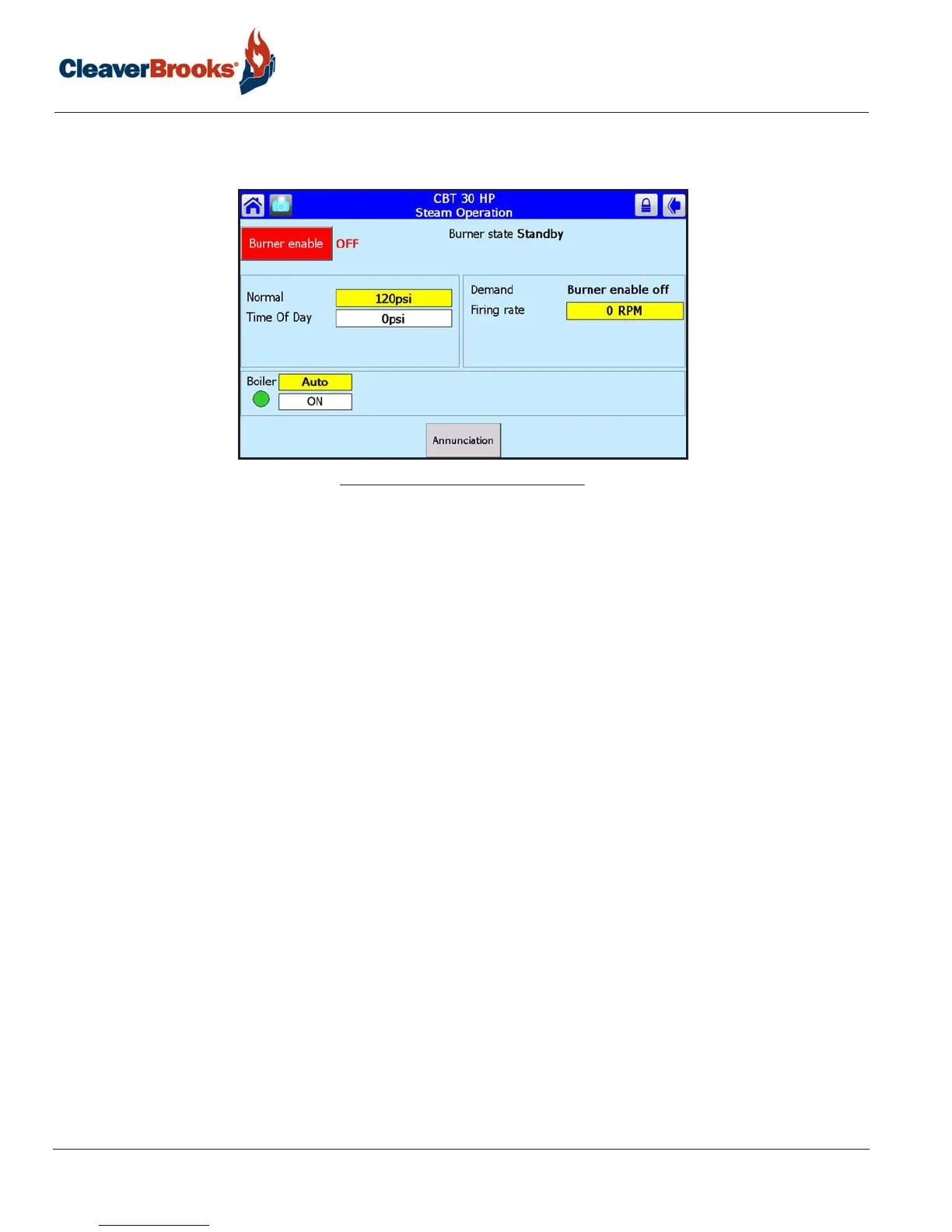

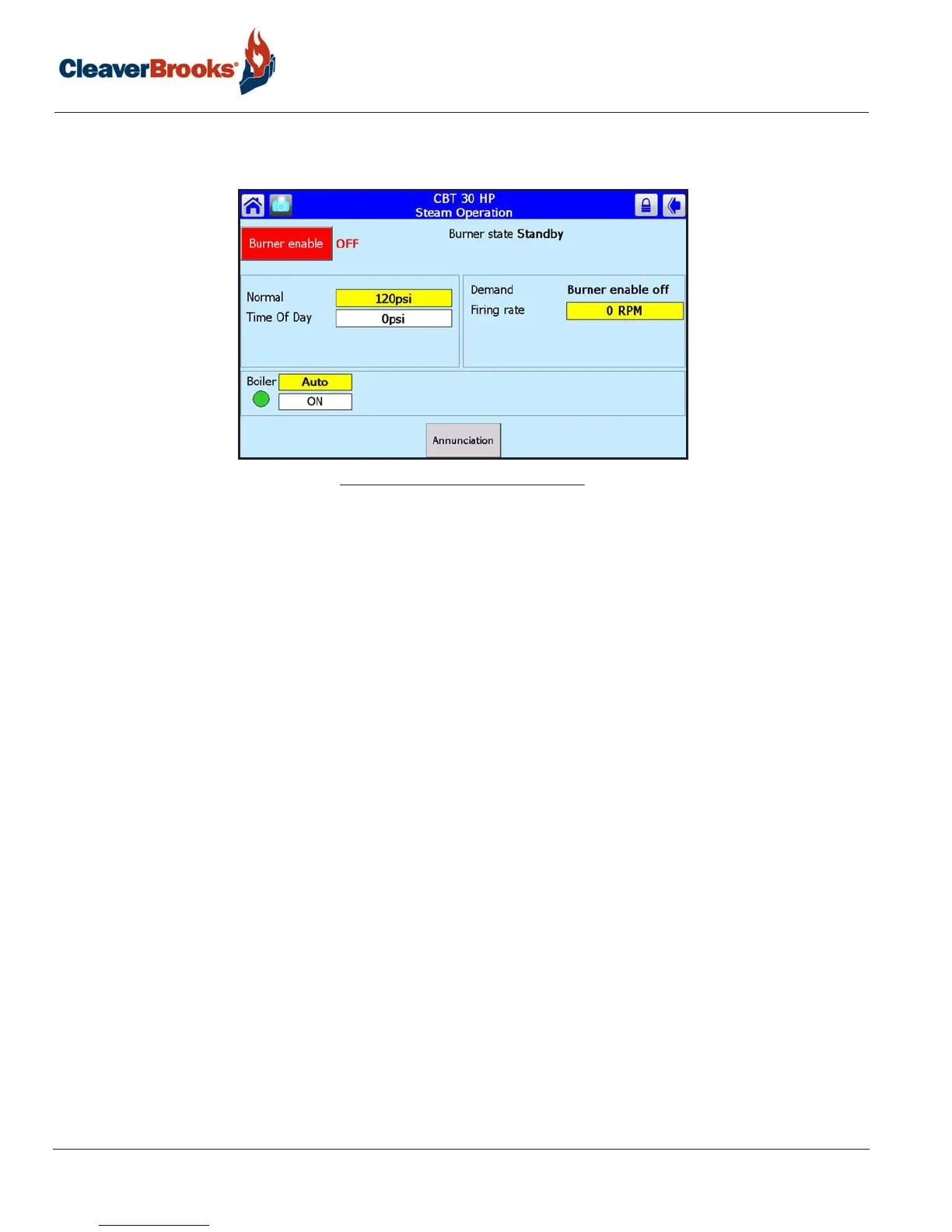

To set combustion:

1. Check inlet gas pressure and reset low gas pressure switch.

2. At Operation screen set firing rate to low fire. Review burner sequence before proceeding.

3. Turn Demand switch to LOCAL.

4. Initiate burner firing sequence. The burner switch is accessed via the CB Falcon Operation page (Figure 4-

15). If the burner does not ignite, adjust choke counterclockwise slightly until you can see a slight yellow

flame at the burner during ignition. Clockwise adjustments to the low-fire offset screw may also be tried.

Check that gas pressure to gas valve inlet is sufficient to fire burner (see Table 4-3 for gas pressure

requirements).

5. After burner lights, maintain in low fire position. At low fire, using main choke on gas valve and a

combustion analyzer set O2 level within 3-8% O2.

6. Manually modulate the burner to high fire. Adjust the gas choke if necessary to obtain desired O2% (6.0% -

7.0%).

7. Modulate to low fire and fine tune offset screw to obtain desired O2% (6.0% - 7.0%).

Verify adjustments by modulating back and forth between low and high fire.

While setting combustion observe gas pressure at low fire and at high fire. Ensure pressure is within limits

shown in Table 4-3.

4.1.20 — Limit Controls Check

The operating (OLC) and high pressure limit (HLC) controls are externally mounted to the control panel. The

setting of the OLC should be slightly higher than the configured set point plus the hysteresis off value set in the

CB Falcon control. The setting of the HLC should be slightly higher than the OLC. For example:

CB Falcon set point = 100.0 psig, Hysteresis Off = 5.0 psi

OLC could be set to 110 psig, HLC set to 120 psig

Specific settings are determined by application and system control scheme.

FIGURE 4-18. Operation screen

Loading...

Loading...