750-382

CBT

2-5

Gas Piping

2.4 — Gas Piping

Gas pressure requirements - For proper and safe operation, each Model CBT boiler requires a stable gas pressure

input. The minimum inlet supply pressure must be as noted in Table 2-3. Pressure should be measured when the

burner is firing using a manometer at the upstream test port connection on the main gas valve. For a multiple

unit installation, gas pressure should be set for a single unit first, then the remaining units should be staged on to

ensure that gas pressure droop is not more than 1" w.c. and never below the required pressure. Fluctuating gas

pressure readings could be indicative of a faulty supply regulator or improper gas train size to the boiler.

*Maximum without upstream regulator

A manually operated shut-off valve is provided as standard on the CBT boiler. If dirt particles are present in the

gas supply, it may be necessary to install an approved gas filter. Please inquire with the local gas supply company.

The boiler shall be installed such that the gas ignition system components are protected from water (dripping,

spraying, etc.) during appliance operation and service.

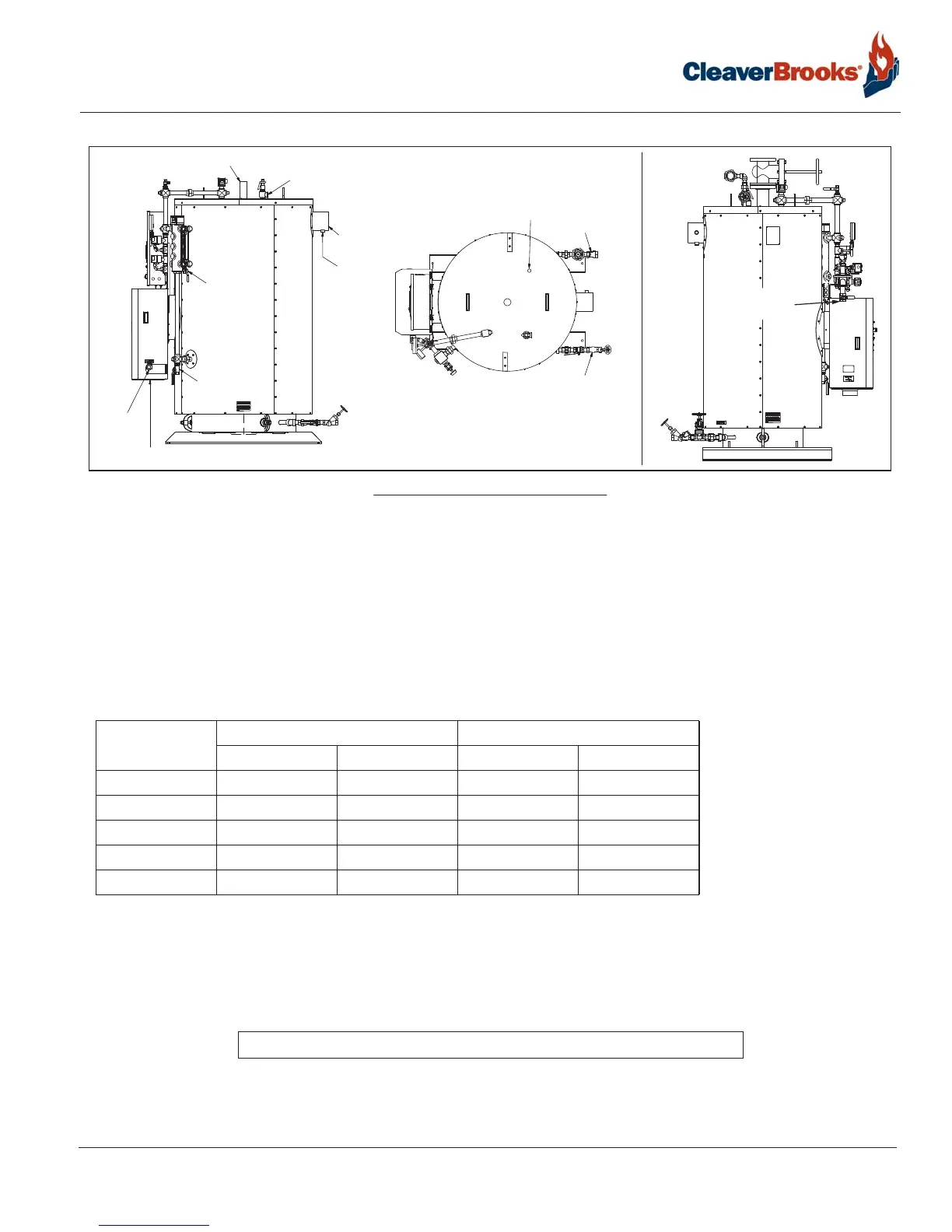

TABLE 2- 3. Model CBT gas pressure requirements

CBT Size

(HP)

Natural Gas LP Gas

Min (“WC) Max (“WC)* Min (“WC) Max (“WC)*

10 7.0 14 11.0 14

15 7.0 14 11.0 14

20 7.0 14 11.0 14

25 7.0 14 11.0 14

30 8.0 14 11.0 14

A sediment trap must be provided upstream of the gas controls.

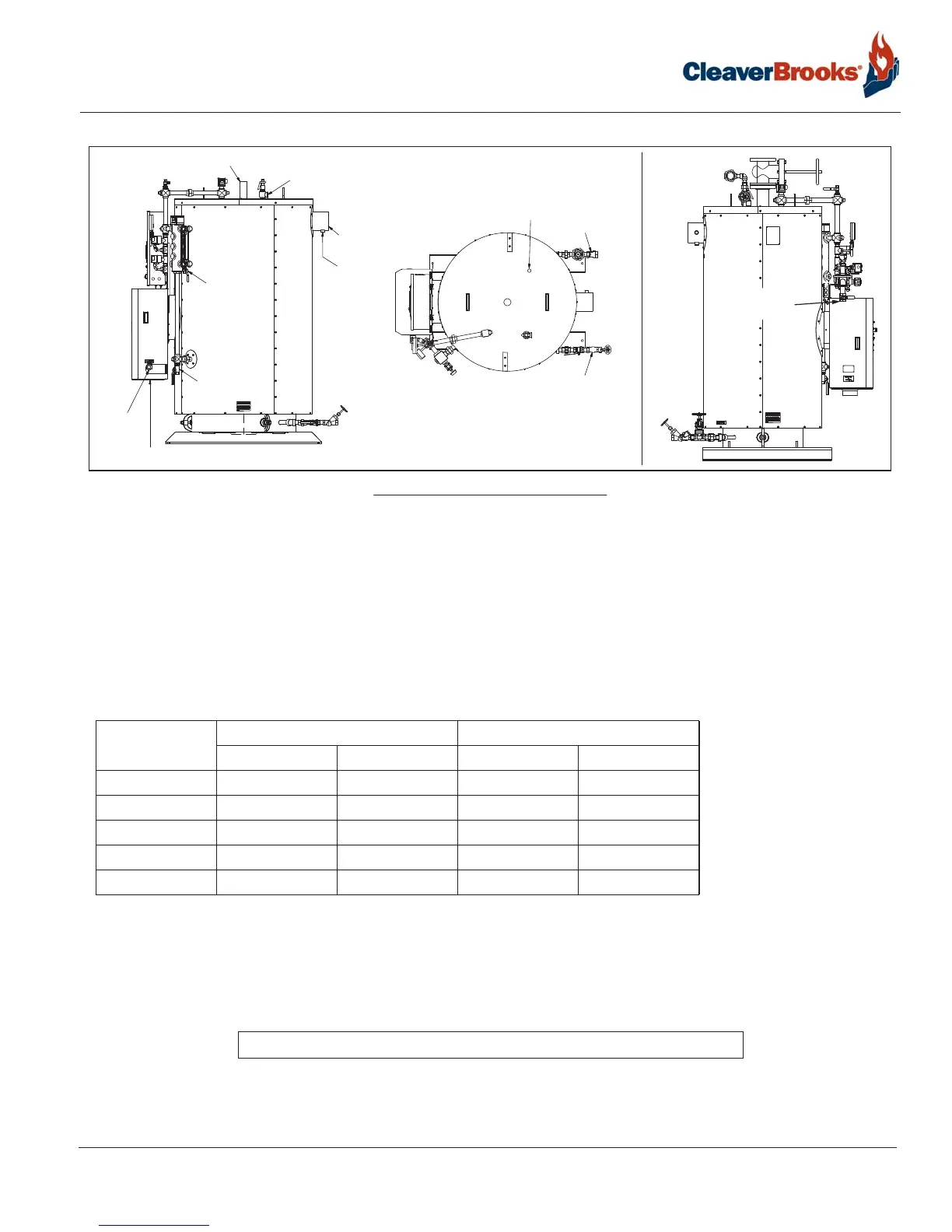

FIGURE 2-3. CBT connections

STACK OUTLET

CONDENSATE

DRAIN

SAFETY RELIEF VALVE

WATER COLUMN

DRAIN

GAS

INLET

GAS INLET

ON/OFF UNITS

STEAM OUTLET

COMBUSTION AIR INLET

SURFACE BLOWOFF

FEEDWATER

BOTTOM

BLOWDOWN

GAUGE

GLASS

DRAIN

Loading...

Loading...