Technical Manual Page 15 CODEL

OPS.080 Issue : C Rev. : Date : 16/7/08 Doc. i/d : 0080/6 Ref. : 080040

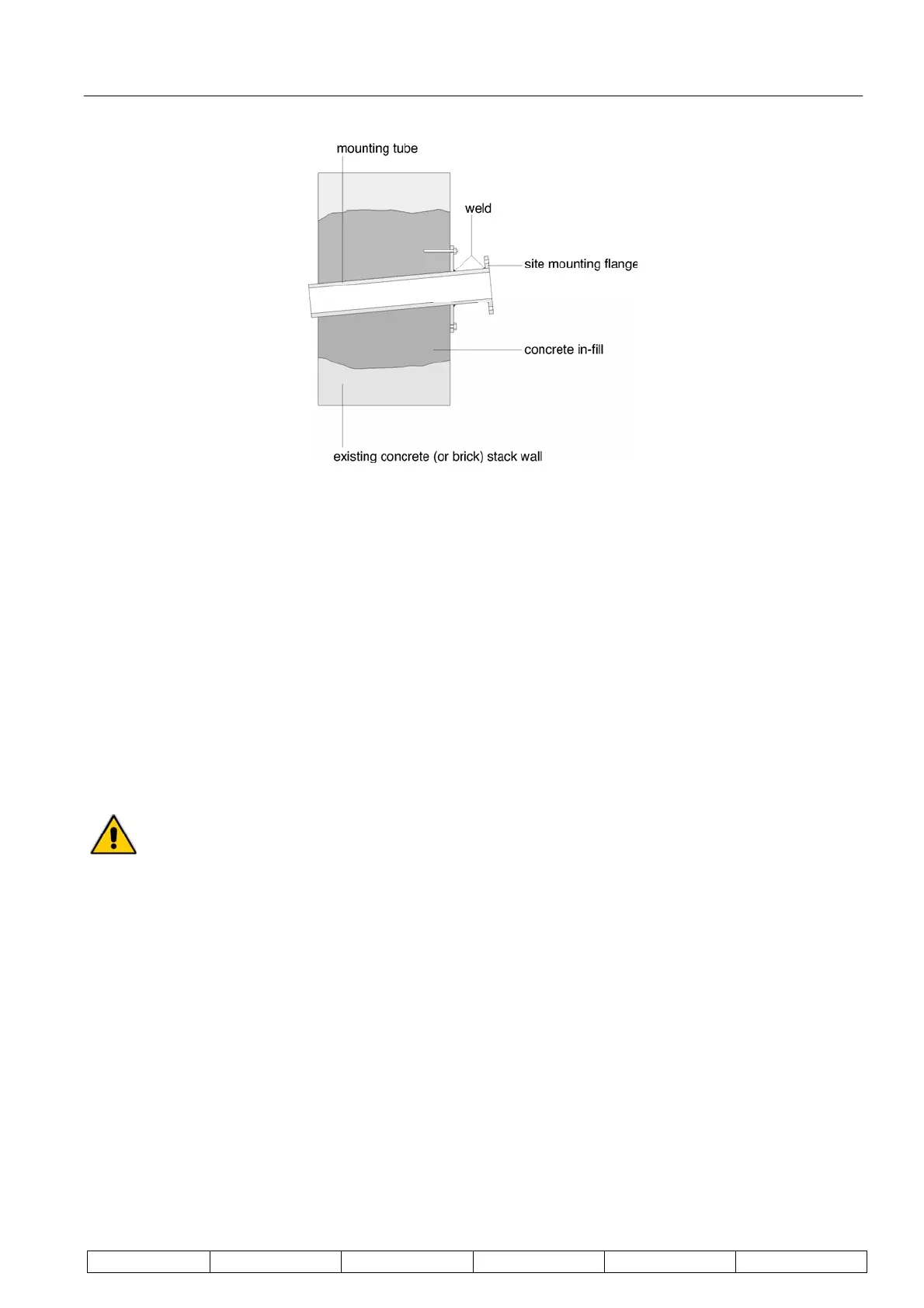

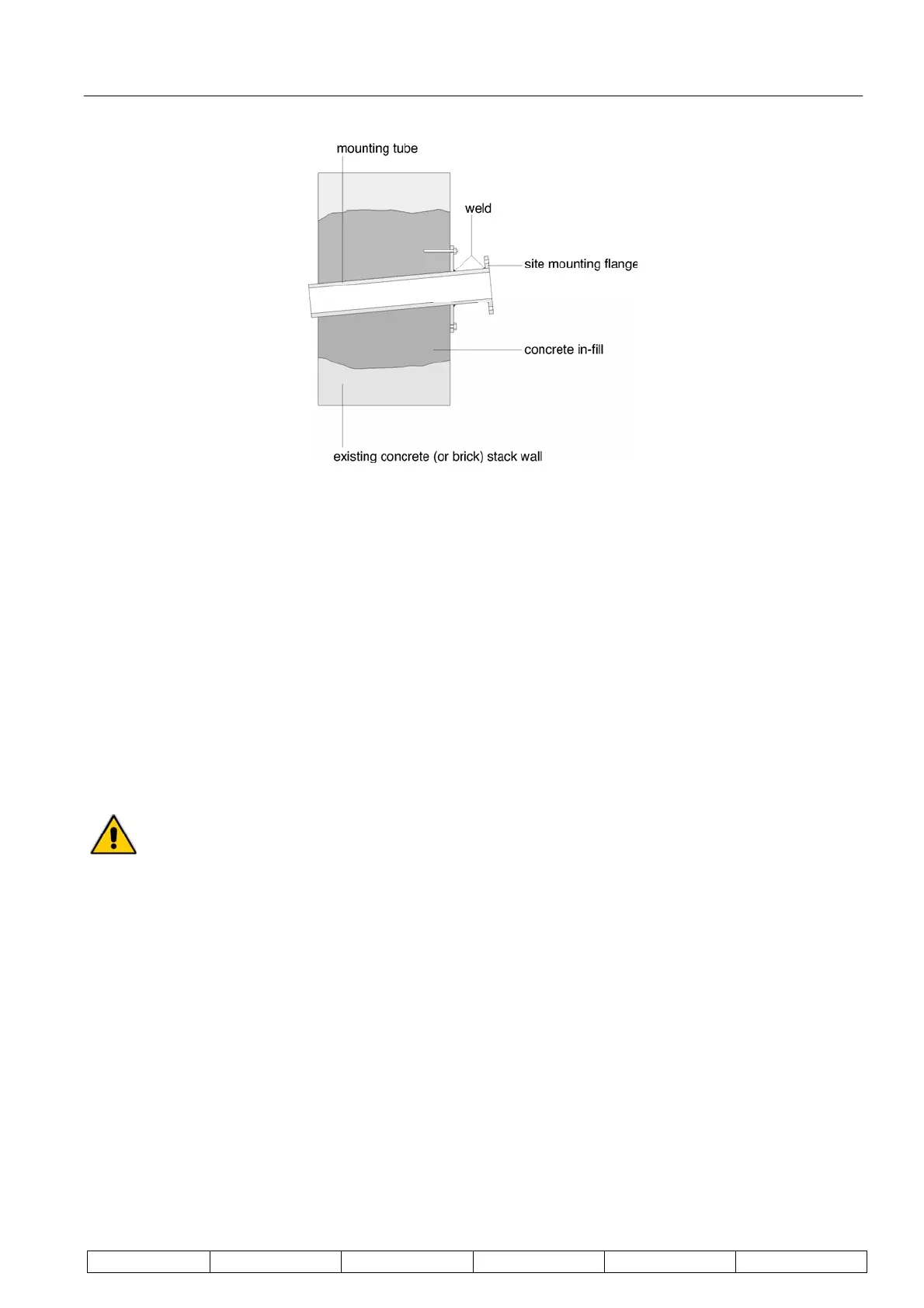

Figure 11 : Typical Stub Pipe Arrangement for Concrete/Brick Stacks

4.3.3. Double Skin Stacks

Double skin stacks are often designed to allow movement between the inner and outer skins, to accommodate

thermal expansion or contraction when plant operation changes. This can cause unacceptable movement of

stub-pipes if mounting arrangements are not designed to maintain alignment. There are too many structural

variations to provide a single solution but, if in doubt, consult CODEL before commencing installation.

4.4. Installation of Purge Air Supply

The GCEM4000 requires air supplies for the pre-measurement zone and to purge the measurement cell for zero

verification. This supply should pass through a proprietary filter unit prior to entering the GCU for further

distribution.

4.5. Installation of Measurement Tube

Before proceeding, note that the probe is heavy (up to approx. 65kg) and is awkward to handle

particularly if access is limited. Ensure that necessary lifting equipment is available and that

precautions are taken to ensure the safety of all personnel whether involved with the

installation or working nearby.

Ease of installation will depend on site conditions. While CODEL or its agents are available to

provide advice on individual site situations, in the interests of safety, this manual does not give

specific installation instructions. Therefore it is important to consider the following:

a) Plan how the job is to be done and have all necessary lifting and safety equipment available.

b) Ensure that all personnel involved know the plan, are adequately protected and that there is no risk

to others working nearby.

c) If the plant is operational during this tube insertion procedure, remember that hot, dirty flue gases

can cause serious injury. All necessary protective clothing, including eye protection, should be worn.

d) Remember that as the tube is inserted further into the duct, the weight and moment exerted by the

tube within the duct will increase, whilst the available length of tube (outside the duct) with which to

control this will decrease.

e) Remember that, if the plant is operating, the tube will get hot with time. Take all necessary

precautions to deal with this.

Loading...

Loading...