Technical Manual Page 22 CODEL

OPS.080 Issue : C Rev. : Date : 16/7/08 Doc. i/d : 0080/6 Ref. : 080040

4.7. Installation of the GCU

Mount the GCU to a suitable load bearing surface wall using 4 x M8 bolts. Connect the compressed air input line

to the input connector and the air lines from the GCU to the neutral zone and measurement zone of the probe.

Connect any span gases to the span inputs of the GCU.

Connect the nylon/PTFE tube to the GCU input and the outputs to the probe. When the tubes have been

connected to the probe, turn on the compressed air. Set the regulator to the neutral zone to 10psi and a flow

rate to the measurement zone of 20 l/min. The regulators are actuated by lifting the black cap and turning; to

lock, press the cap down. The compressed air must be clean and dry as detailed in Section 2. Summary

Specification.

4.8. Wiring Connections

Wiring should only be undertaken by a qualified technician. Ensure that the power supply to

the unit is isolated.

DO NOT switch power on to the unit until all installation is complete and the system is ready

for commissioning.

Cables supplied with ferrite beads fitted to cores are intended to protect against interference

and should not be modified without consulting CODEL.

The GCU is supplied with all internal cables fitted. External cables supplied by the customer should be

connected in accordance with the connection schedule supplied with the GCU. The connection schedule is

project specific.

4.8.1. Installation and Connection of Cables

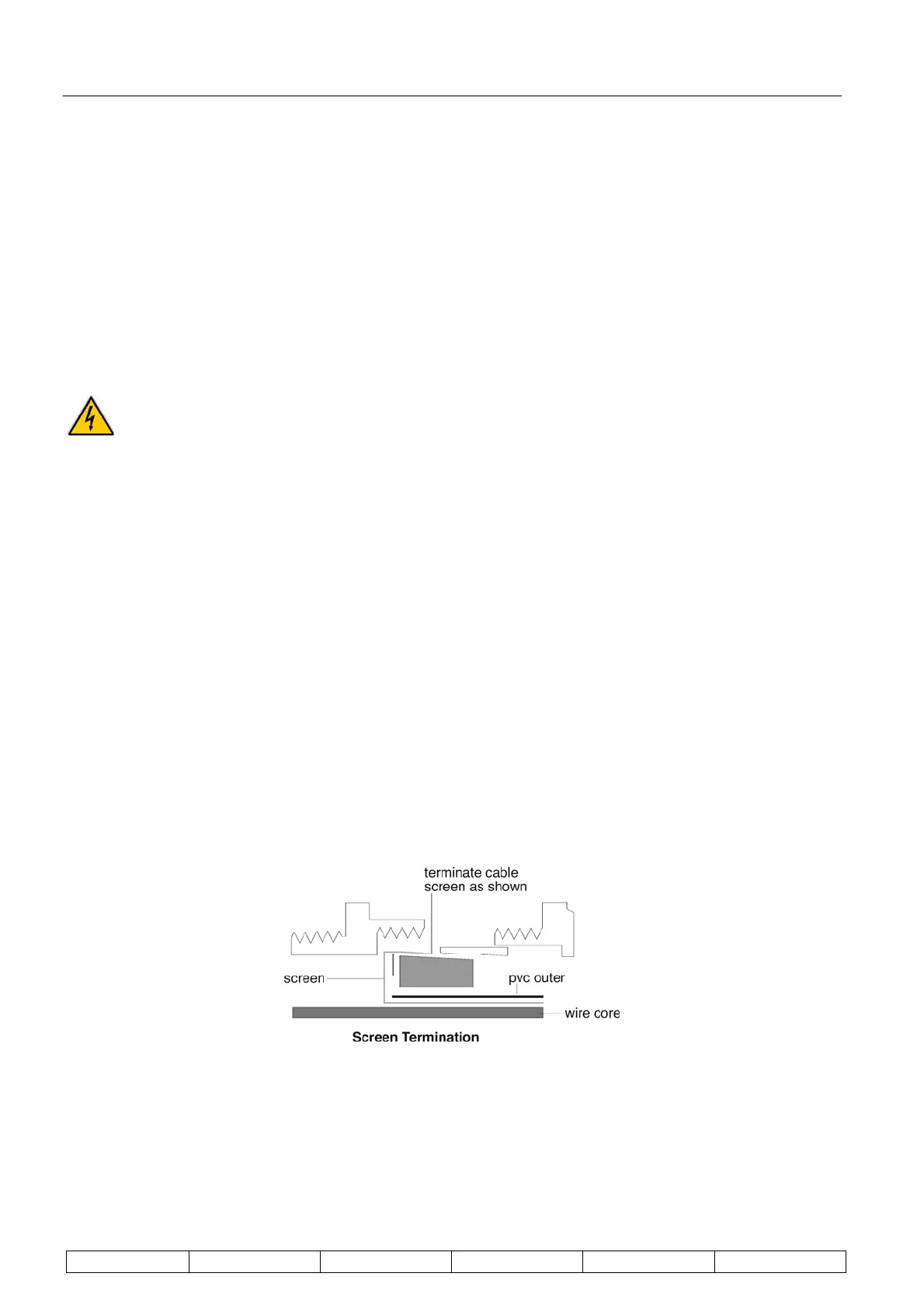

Decide routing for all non-power cables (both those supplied by CODEL and those sourced locally). Use

common routing wherever possible and install leaving sufficient free-end length to make final connections.

Power cables should be installed separately using different routes if possible to reduce the risk of cross-

interference. Leave sufficient free-end length to make final connections.

All units are supplied with cable gland entries fitted with blanking plugs. Cable glands are packed separately. To

fit a cable gland, remove the appropriate blanking plug with a spanner, remove the locking nut from the cable

gland, screw the cable gland into the threaded hole from the outside and tighten by hand to compress the seal.

Re-fit the locking nut from inside the case and tighten.

Figure 14 : Cable Gland

4.9. Installation of Normalising Measurements (Oxygen, Temperature and Pressure)

The GCEM4000 is supplied with a pressure and temperature inputs fitted as standard for normalising purposes.

If oxygen is connected a normalising input signal is required. Referring to the contract-specific connection

schedule, connect the 4-20mA output from the oxygen sensor to the GCU.

Loading...

Loading...