Maintenance

97

C3M2-OM-EN-02

Note

The recommended maintenance intervals in the maintenance schedule are

for maintaining trucks operating in normal conditions.

More frequent maintenance will be required if the truck is being operated in

an arduous manner or in a harsh or aggressive environment. The frequency

is governed by application and must be determined by the user.

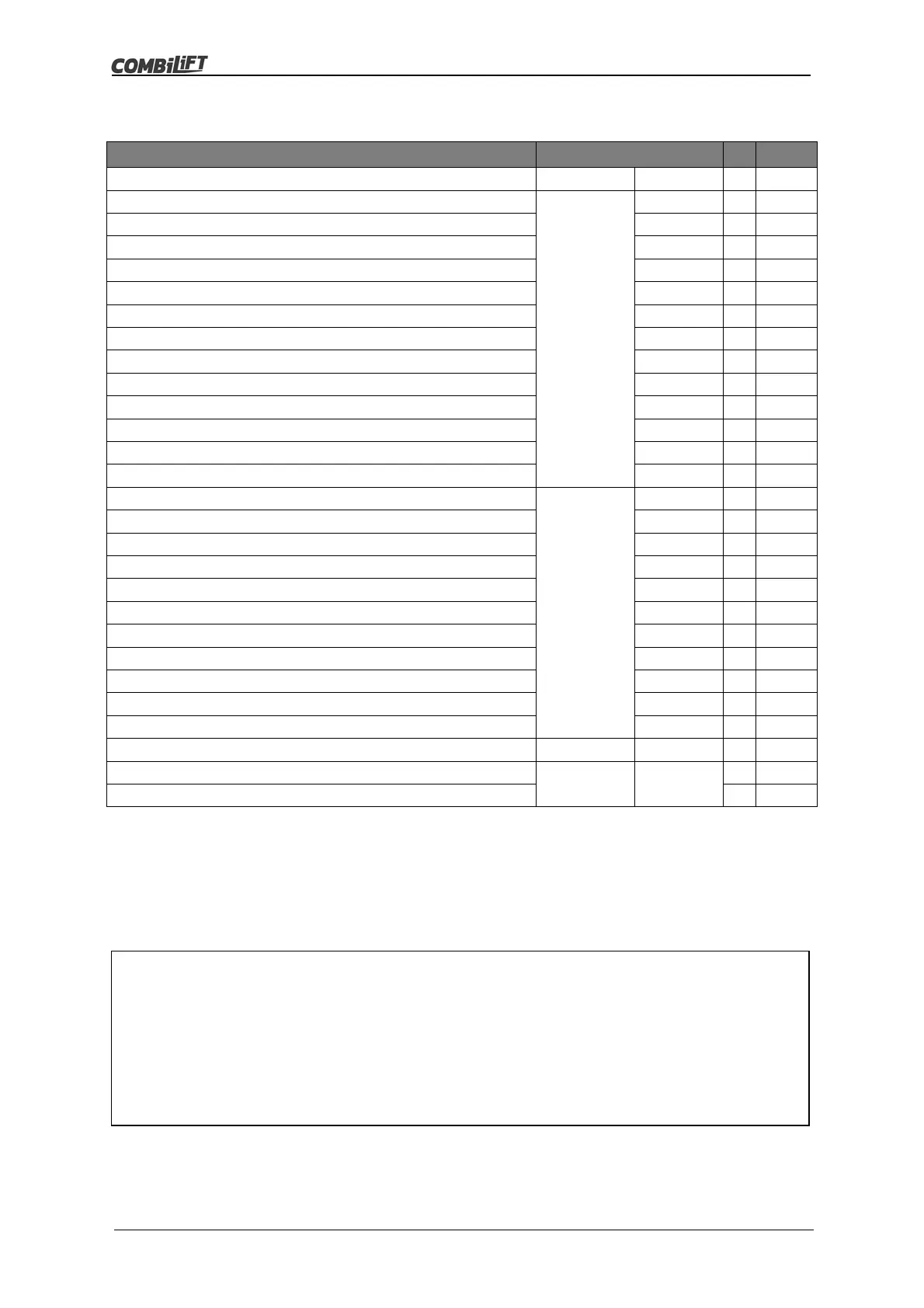

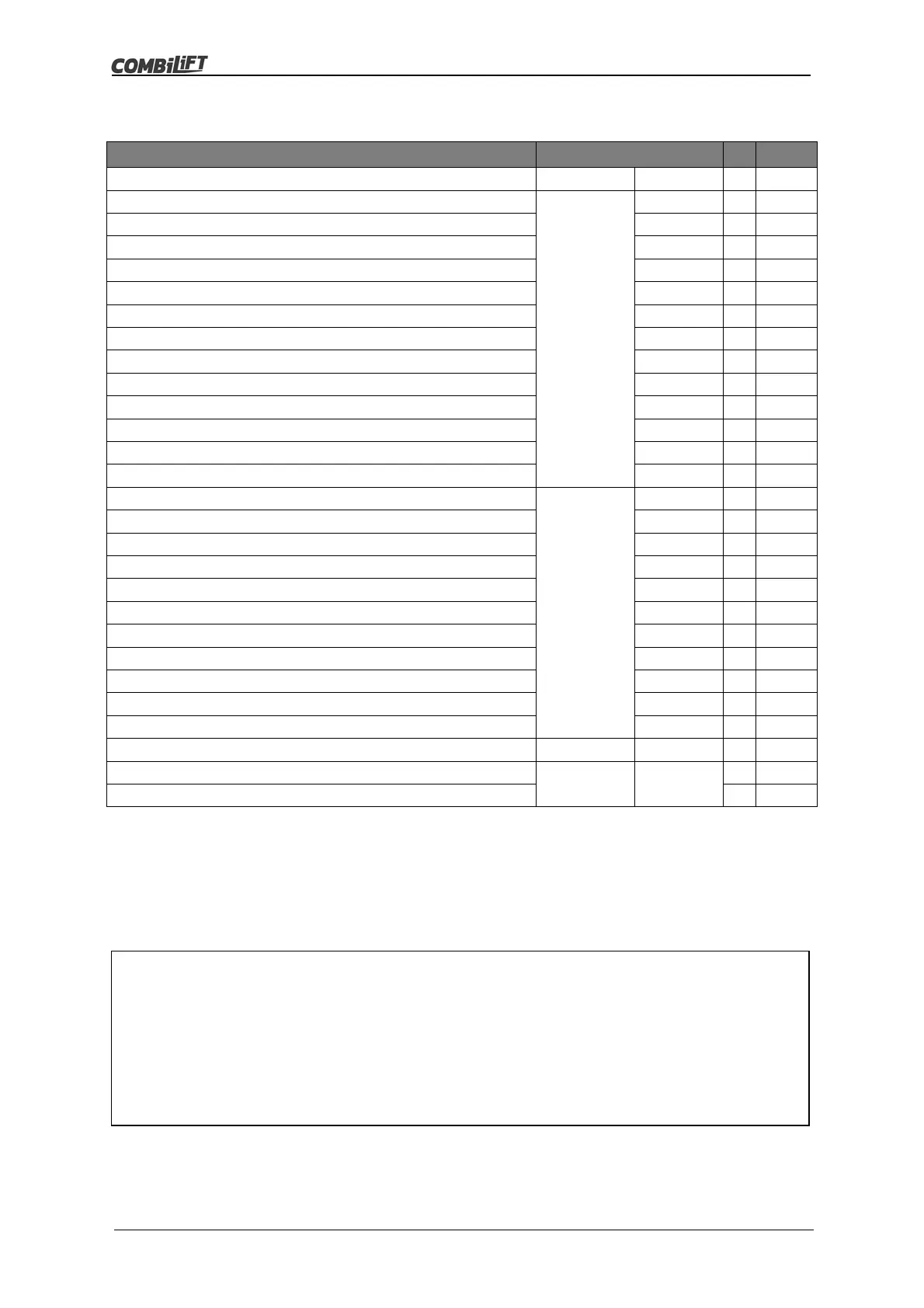

6.3 General Truck Maintenance Schedule

Maintenance Task Interval - Every

✔

Page

Grease All Points Marked on the Grease Point Chart

100 Hours 3 Months

101

Check All Electrical Connections/Terminals

250 Hours

Check All Nuts And Bolts Are Present & Secure

Check All Instruments & Warning Devices

Check Operation of Brakes, Steering & Hydraulic Functions

6 Months

Check All Lights (i.e. Work Lights, Road Lights & Safety Lights)

6 Months

Check the Tyres

6 Months

Check all Hydraulic Cylinder Chrome Rods for Dirt & Damage

6 Months

Check the Routing of all Hoses, Pipes & Wires

Check Battery Electrolyte Levels

6 Months

119

Inspect & Lubricate Mast Chains, Measure Chain Stretch

6 Months

130

Grease Mast Channels

6 Months

128

Grease Mast Carriage Channels (Where Wear Pads Run Only)

6 Months

Torque All Wheel Nuts

96

Check Hydraulic Oil Level

500 Hours

72

Check Hydraulic Oil Cooler – Clean Fins If Necessary

1 Year

Check the Mast Bearings

134

Check the Mast Bearing Wear Pads and Adjust (If Applicable)

134

Check Mast Carriage Bearings, Ensure Locknuts are Tight

Check Mast Carriage Wear Pads & Alignment

135

Check the Forks

1 Year

136

Check Swivel Slew Ring Bearings

Check the Operator’s Cabin & Door for Structural Damage

1 Year

Change Hydraulic Suction Filter Element

1 Year

123

Change Hydraulic Return Filter Insert

1 Year

124

Check Hydraulic System for Damage, Wear and Leaks

1000 Hours 2 Years

Change Hydraulic Oil & Strainer Filter (In-Tank)

2000 Hours 3-4 Years

126

Change the Hydraulic Tank Breather

127

Perform the tasks in the truck maintenance schedule above, after the period of

operating hours or the calendar period as they first arise to keep the truck in optimum

working condition.

Perform all checks on the pre-use check sheet in conjunction with the maintenance

schedule tasks (see page 149).

Loading...

Loading...