C4-C5XL MK3 O&S

4-7

C4000MK3-OM-EN-11

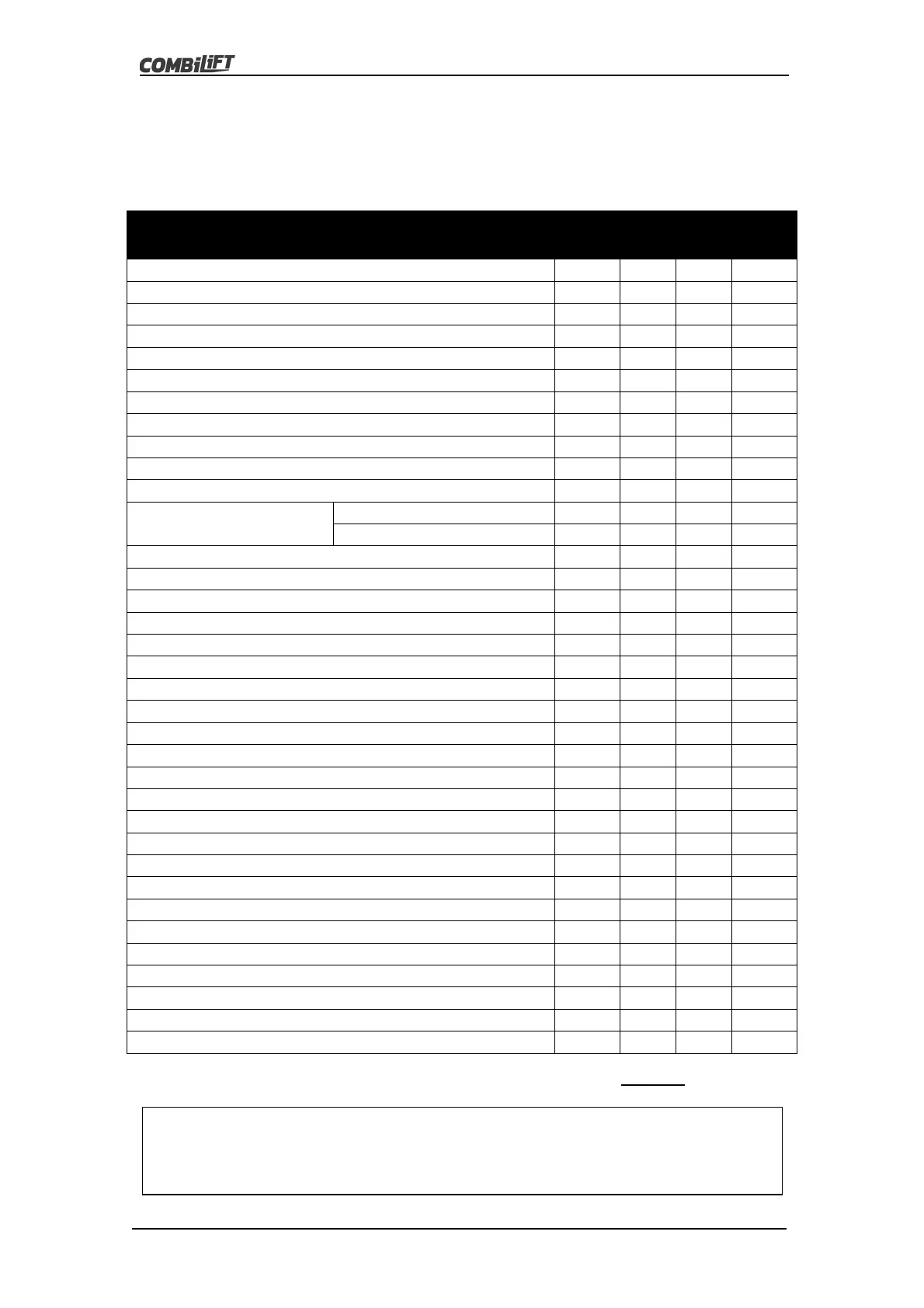

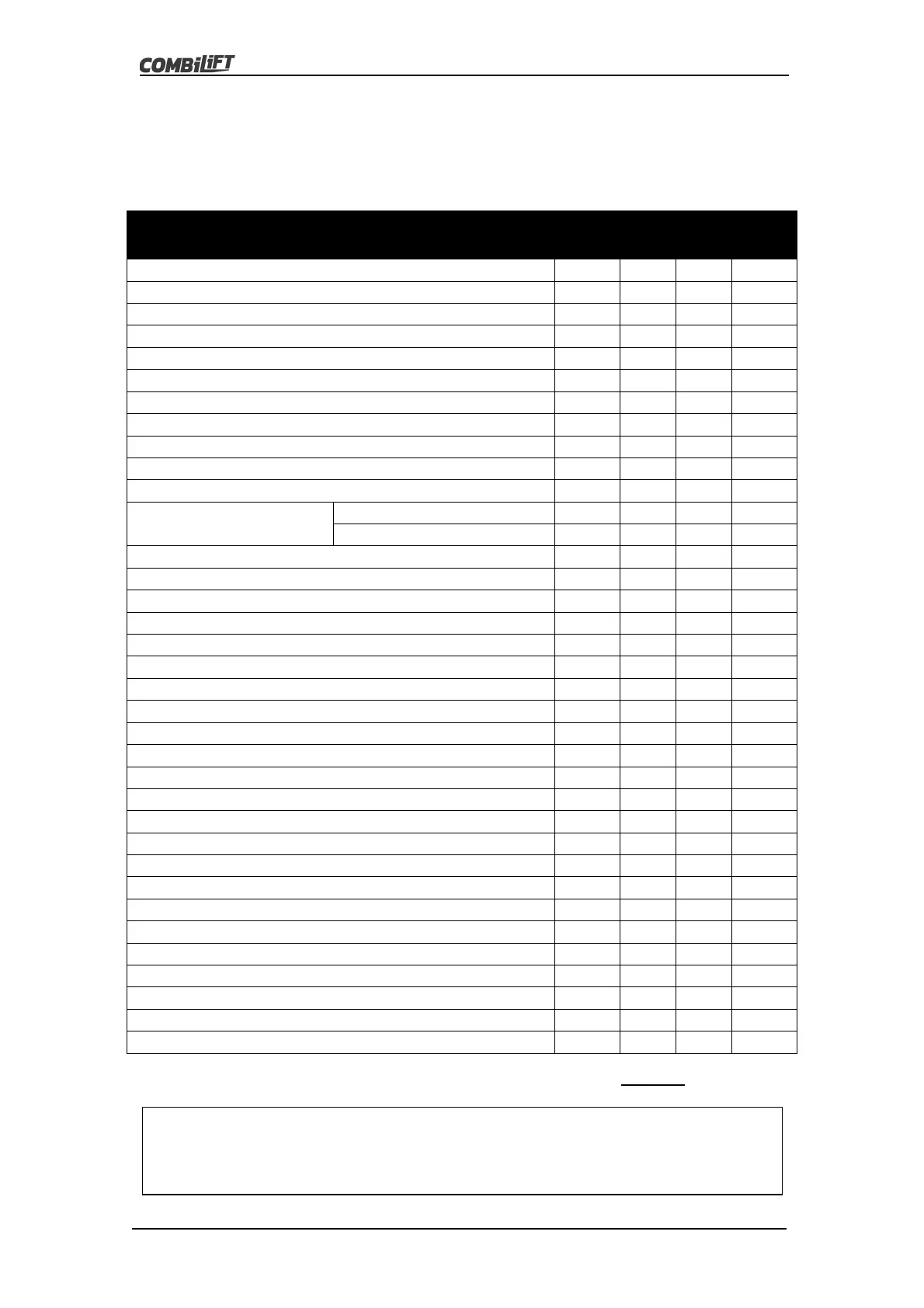

4.4: Maintenance Schedule

In order to keep the Combilift in optimum working condition it is necessary to

service the truck at regular intervals. The Chart below details the intervals (in

hours of machine operation) at which maintenance tasks should be performed

Grease All Points Indicated on the Grease Point Chart Weekly

Action

Service Interval (Hrs)

Daily 250 500 2000

Check Engine Oil

●

Change Oil Filter Cartridge ●

Change Engine Oil ●

Change Air Filter Cartridge (clean every 100hrs) ●

Change Air Filter Cartridge ●

Change Diesel Engine Glow plugs ●

Change LPG engine Spark Plugs ●

Check Engine Mounts ●

Check Engine Mount Bolts ●

Check Engine Idling Speed ●

Change Both Diesel Fuel Filters ●

Engine Belts

Check for Wear ●

Check Tension ●

Check Cooling Fan ●

Check Radiator ●

Check Engine Coolant Level ●

Change Coolant in Cooling System ●

Check Oil Cooler ●

Check Hydraulic Oil Level ●

Change Hydraulic Oil ●

Change Hydraulic Suction Filter Cartridge ●

Change Hydraulic Return Filter Cartridge ●

Change Hydraulic In-Tank Strainer Filter ●

Check Battery Electrolyte levels ●

Check Swivel Bearings (Slew Rings) ●

Check Mast Carriage Bearings ●

Check Mast Carriage Wear Pads & Alignment ●

Check Mast Bearings ●

Check Mast Chains ●

Lubricate & Adjust Mast Chains ●

Grease Mast Channels ●

Grease Mast Carriage Channels ●

Check Wheel Nuts ●

Torque Wheel Nuts ●

Check Hydraulic Hoses for Leaks ●

Check Hydraulic Hoses for Signs of Wear ●

Note

Maintenance, replacement, or repair of the emission control devices and systems

may be performed by any non-road engine repair establishment or individual.

Loading...

Loading...