5-7

FUEL SYSTEM

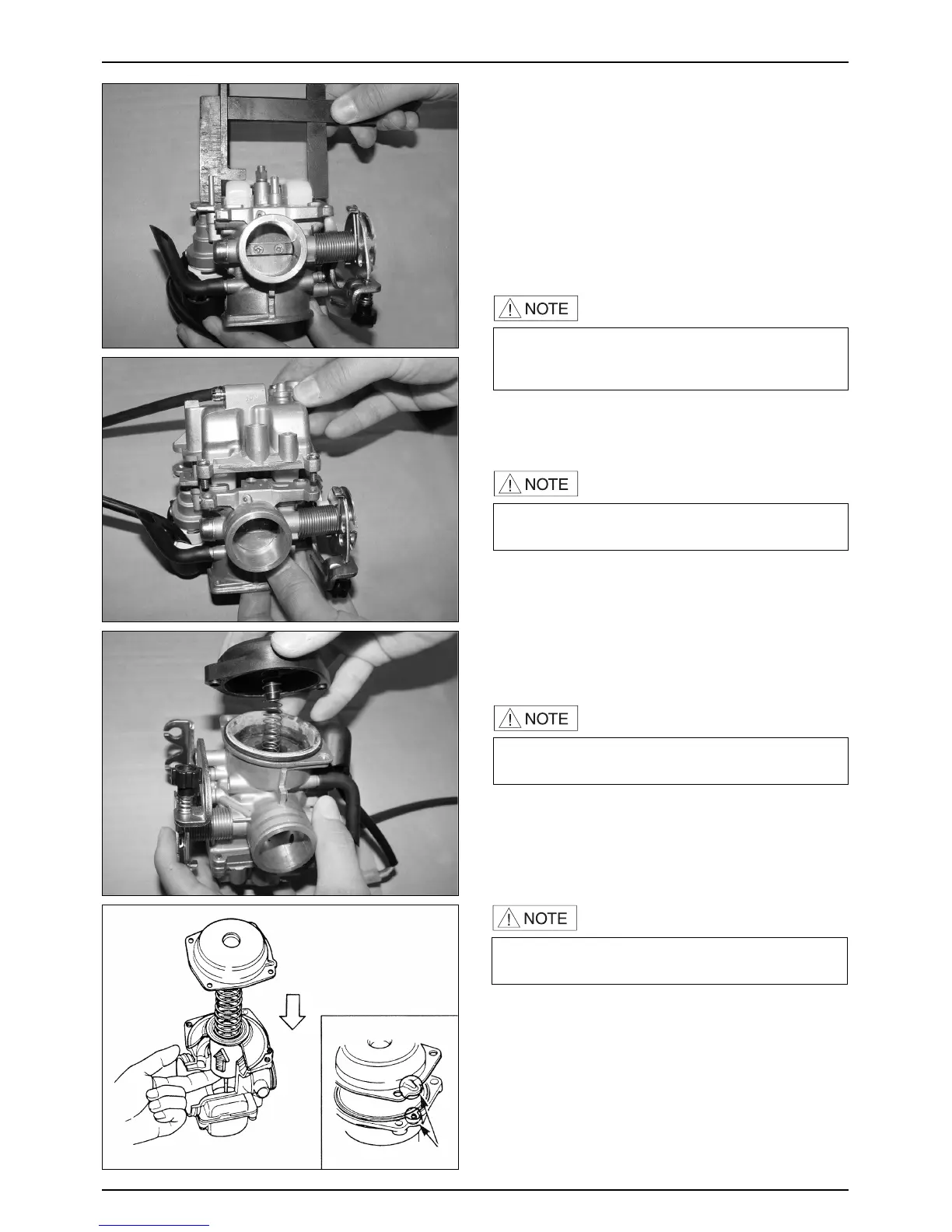

FLOAT LEVEL INSPECTION

● Install the float valve, float, float pin.

● Measure the float level with the float level gauge.

FLOAT LEVEL : 13 mm

TOOL : FLOAT LEVEL GAUGE

● If the level is out of specification and the float arm lip

can be bent, adjust the float level by bending the lip.

Non-adjustable floats must be replaced.

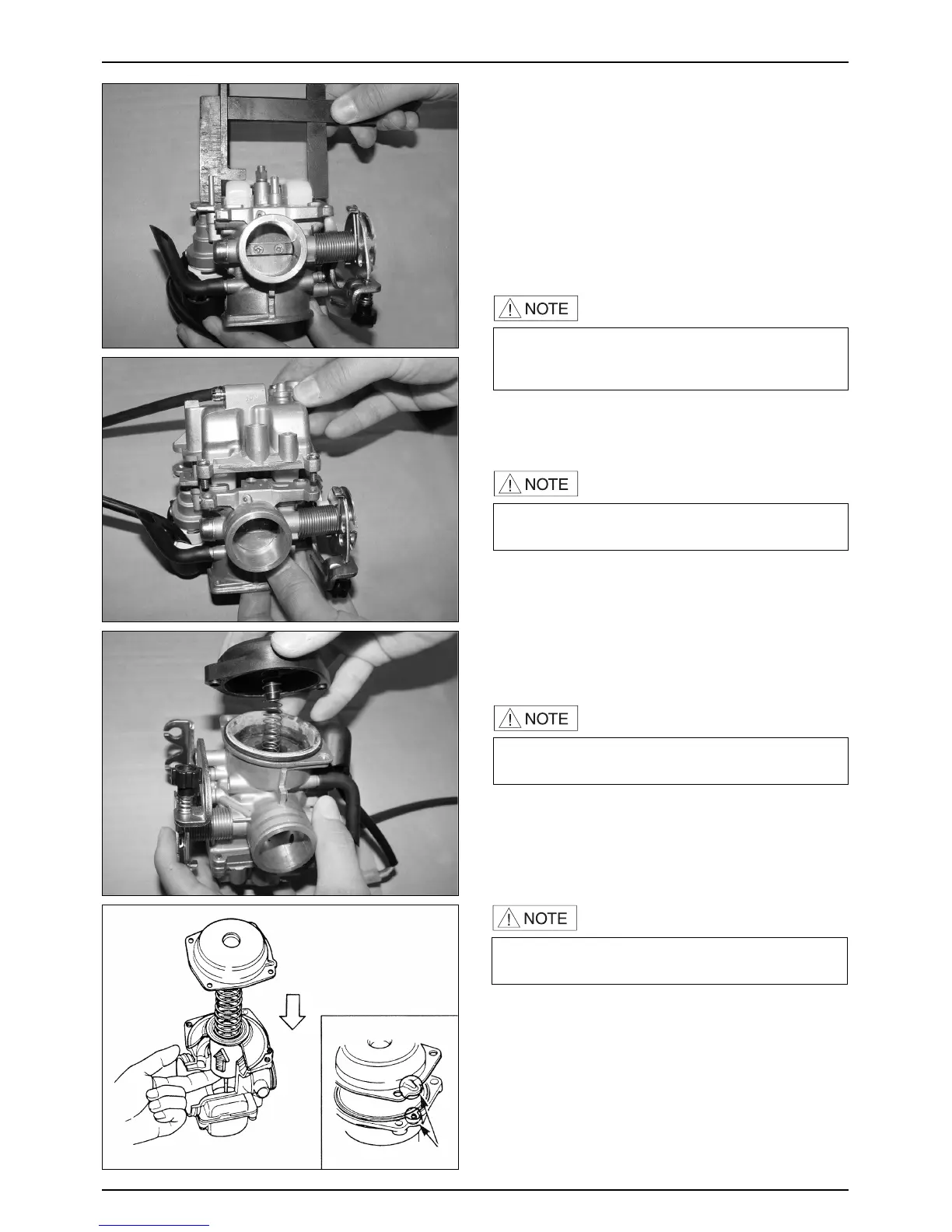

● Insert the jet needle, needle spring holder, needle

spring, diaphragm assembly, and install the needle

screw.

● Install the diaphragm assembly on the carburetor body.

● Install the diaphragm spring.

● Install the diaphragm cover with its cutout aligned with

the hole in the tab of diaphragm.

● Install the auto bystarter wiring plate to the diaphragm,

and tighten the 4 pan screws.

● Install the drain tube and air-hose.

● Install the float body assembly, install the bracket and 4

pan screws.

•Be sure to keep the float level at the specified height.

If the float level is low / high, fuel mixture becomes

lean / rich.

•Be sure to replace the float chamber body O-ring

with the new one.

•Install the jet needle aligned with the grooves in the

diaphragm.

•Be careful not to pinch the diaphragm, and to keep

the spring straight.

COMPRESS STRAIGHT

ALIGN

Loading...

Loading...