11-1

11. CYLINDER / PISTON

SERVICE INFORMATION

GENERAL SAFETY

Be careful not to damage the mating surfaces by using a screwdriver when disassembling the cylinder. Do not strike the

cylinder too hard during disassembly, even with a rubber or plastic mallet, to prevent the possibility of damage to the

cylinder fins.

Take care not to damage the cylinder wall and piston.

SPECIFICATIONS

TROUBLESHOOTING

Compression too low Overheating

Worn piston Excessive carbon build-up on top of piston

Worn, damaged piston ring

Worn cylinder

Abnormal noise

Excessive smoke

Worn cylinder and piston

Worn cylinder, piston or piston rings Worn connecting rod small end bearing or piston pin

Improper installation of piston ring Damaged piston ring

Scored or scratched piston or cylinder Excessive carbon build-up on top of piston

SERVICE INFORMATION

······

11-1

TROUBLESHOOTING

········

11-1

CYLINDER REMOVAL

········

11-2

PISTON / PISTON RING

····

11-3

CYLINDER INSTALLATION

··

11-6

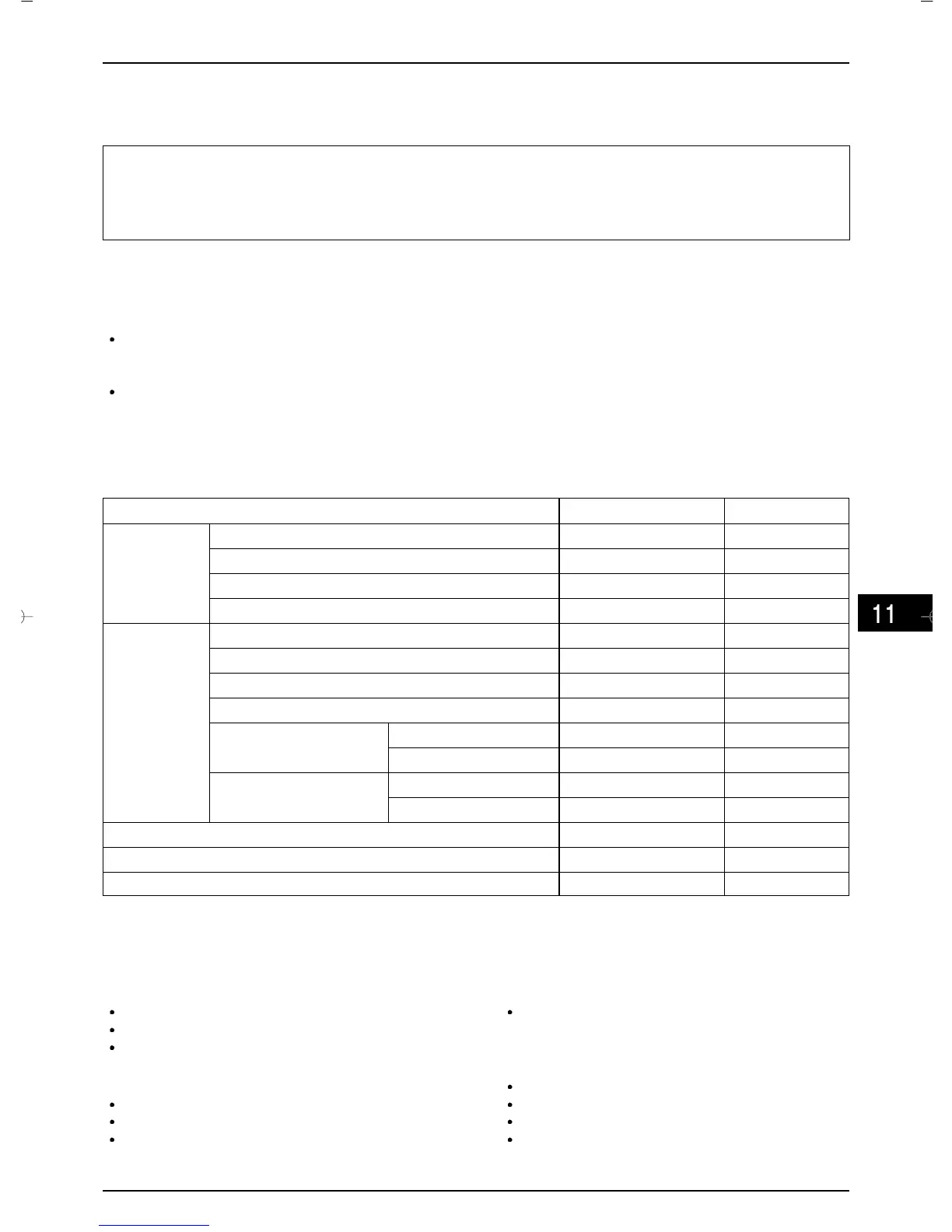

ITEM STANDARD VALUE SERVICE LIMIT

Unit : mm

73.10

0.10

0.05

0.10

72.60

17.04

16.96

0.02

0.09

0.09

0.50

1.10

0.30

17.06

0.04

73.005~73.015

-

-

-

72.985~72.965

17.002~17.008

16.994~17.000

0.002~0.014

0.015~0.045

0.015~0.045

0.35~0.45

0.20~0.70

0.020~0.050

17.010~17.028

0.010~0.034

INNER DIAMETER

CYLINDERICAL

ROUNDLESS

HEAD CONTACT WARPAGE

PISTON SKIRT OUTER DIAMETER

PISTON PIN HOLE INNER DIAMETER

PISTON PIN OUTER DIAMETER

PISTON-TO-PISTON PIN CLEARANCE

CYLINDER

PISTON RING-TO-

GROOVE CLEARANCE

PISTON RING

JOINT GAP

TOP

SECOND

TOP / SECOND

OIL RING (SIDE RAIL)

PISTON,

PISTON PIN,

PISTON RING

CYLINDER-TO-PISTON CLEARANCE

CONNECTING ROD SMALL END INNER DIAMETER

GAP BETWEEN CONNECTING ROD SMALL END AND PISTON PIN

Loading...

Loading...