©

200324 3-3

Inspection and adjustment

PE ENGINE INLET/EXHAUST SYSTEM

CF65/75/85 series

4

6

3.3 INSPECTION AND PRESSURE TESTING, AIR INLET SYSTEM

}

When pressure testing the air intake

system, the plugs may spring off if

they are not properly secured.

Check the condition and mounting of the air inlet

channels/pipes of the air intake system.

In case of doubt as to the proper sealing of the air

intake system, which is indicated by the following:

1. loss of power

2. high fuel consumption

3. unusual sounds,

carry out a pressure test to check the air inlet

system for leaks.

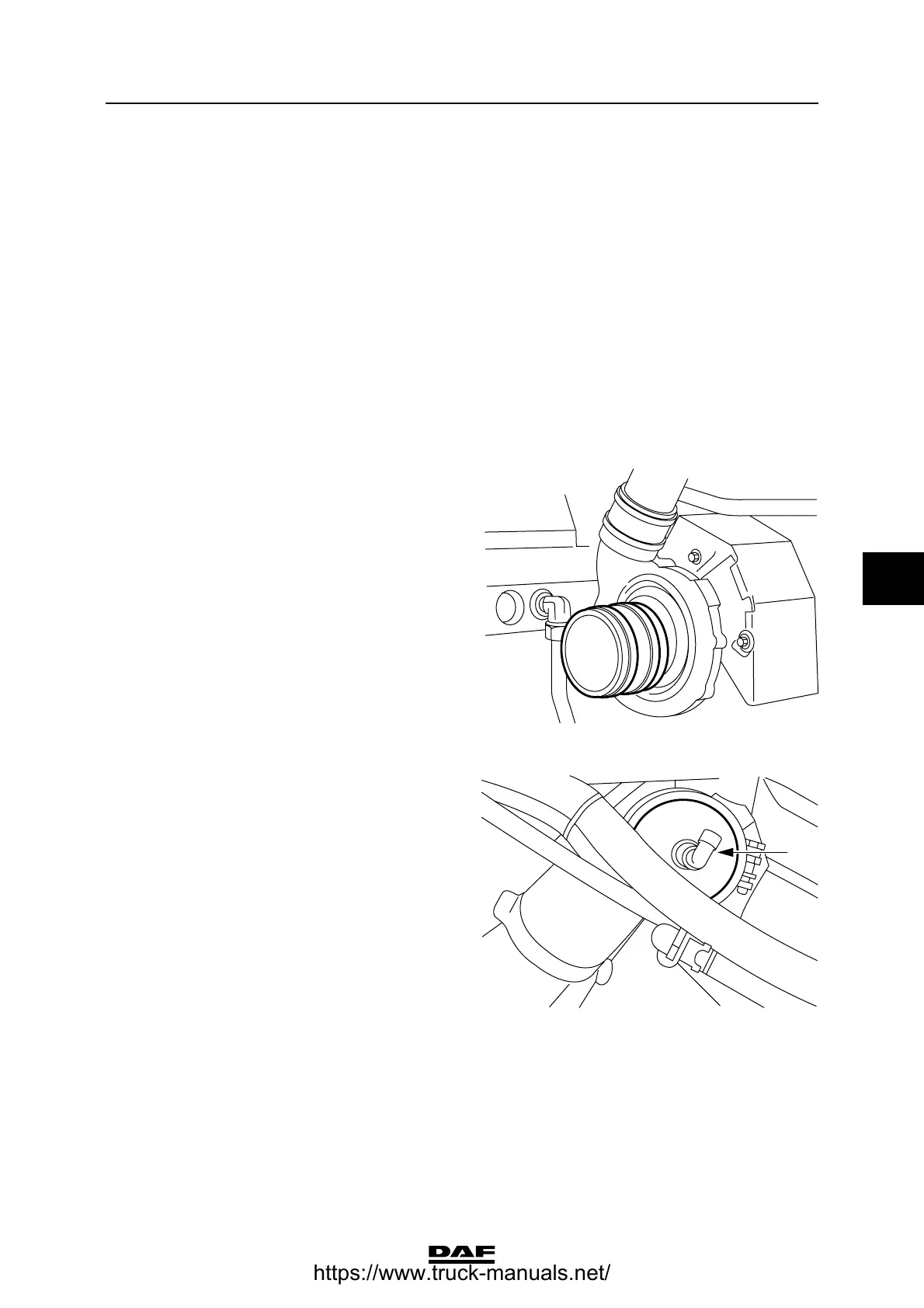

1. Remove the pipe between the air filter

housing and the intake port on the suction

side of the turbocharger.

2. Fit the special tools (DAF no. 1329320) and

(DAF no. 1329403) to the suction side of the

intake port and plug the opening.

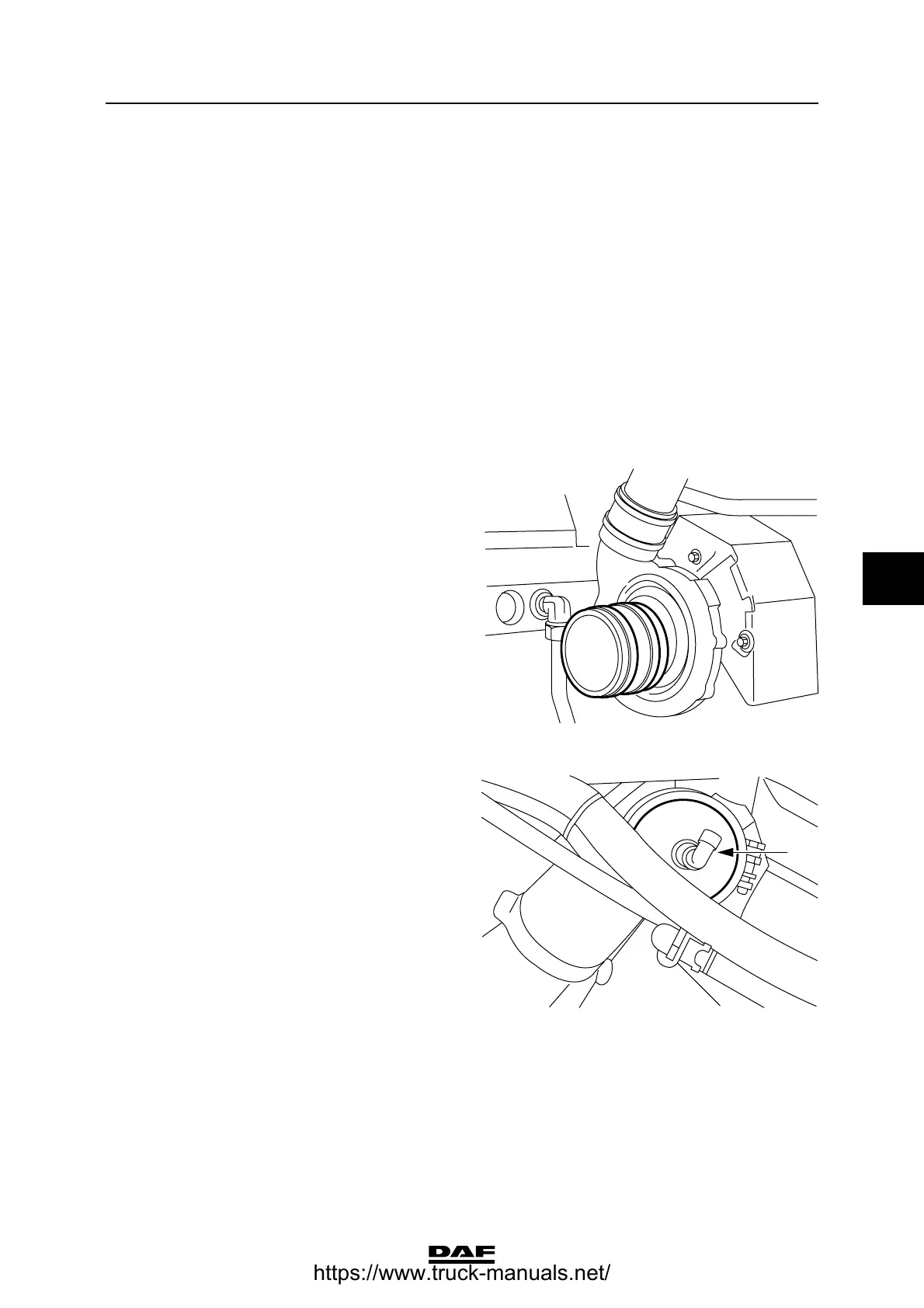

3. Remove the air inlet hose between the air

cooler and the inlet manifold.

4. Fit the special tool (DAF no. 0694831) onto

the air cooler.

5. Connect a flexible air pipe with reducer valve

to the coupling (A) and charge the system to

approx. 1 bar.

6. Use a soapy solution to check the whole inlet

system for air leaks. Also check whether the

pressure gauge of the reducer valve drops.

i 400376

A

i400325

https://www.truck-manuals.net/

Loading...

Loading...