CE ENGINE FUEL SYSTEM

4-10

©

200416

Inspection and adjustment

2

ΧΦ65/75/85 series

4

Locating internal fuel leak

1. Take the injector pipe out of cylinder 1.

2. Seal the connection of cylinder 1 on the fuel

rail using the special tool

(DAF no. 1453133). Tighten the plug to 30

Nm.

3. While the engine is idling, use a stop watch

to measure the time required to fill a

measuring beaker with 360 ml of return fuel.

See "Technical data" for the minimum time

permitted for filling the measuring beaker.

Note:

Use a measuring beaker with a mark at

360ml.

4. Remove the special tool (DAF no. 1453133)

and reconnect the injector pipe.

5. Repeat the above steps for the other

cylinders and note the values.

Note:

When the leaking cylinder has been plugged,

the quantity of return fuel will decrease and,

as a result, the time it takes to fill the

measuring beaker to 360ml will increase.

If several high values are measured, this

indicates that there may be several leaks. If

this is the case, first check the cylinders that

give the highest values and then repeat the

test.

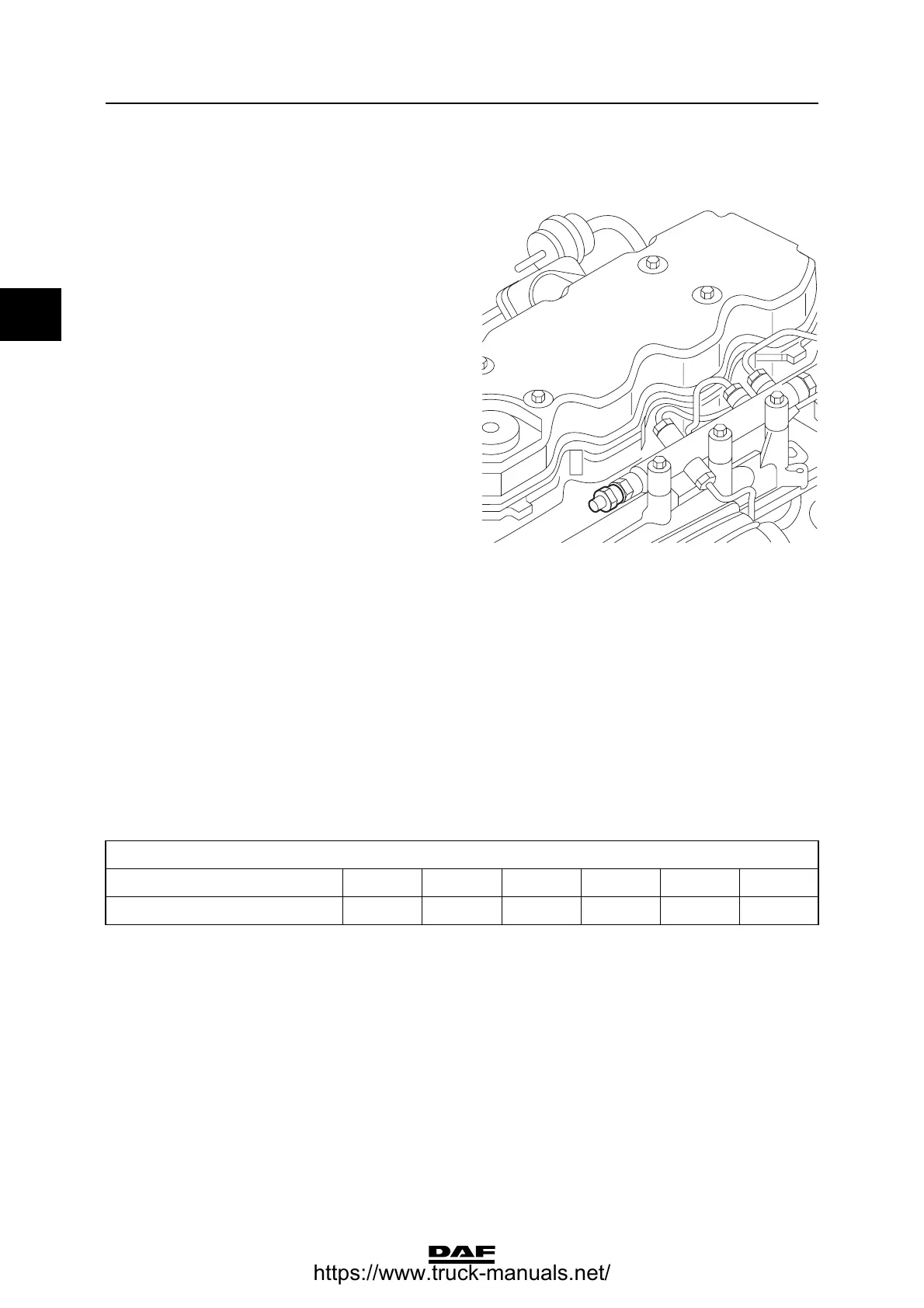

In the example shown in the table below

there is an internal leak in the 5

rd

cylinder,

which could be caused by a leak in the fuel

supply pipe and/or a defective injector.

Example:

6. In the event of a leak, remove the fuel supply

pipe and the injector of the cylinder in

question; see "Removal and installation".

i400681

Leak test results

Blocked cylinder 1 2 3 4 5 6

Time (s) to fill to 360ml 35 36 35 37 150 38

https://www.truck-manuals.net/

Loading...

Loading...