©

200416 3-3

Description of components

CE ENGINE FUEL SYSTEM

ΧΦ65/75/85 series

4

2

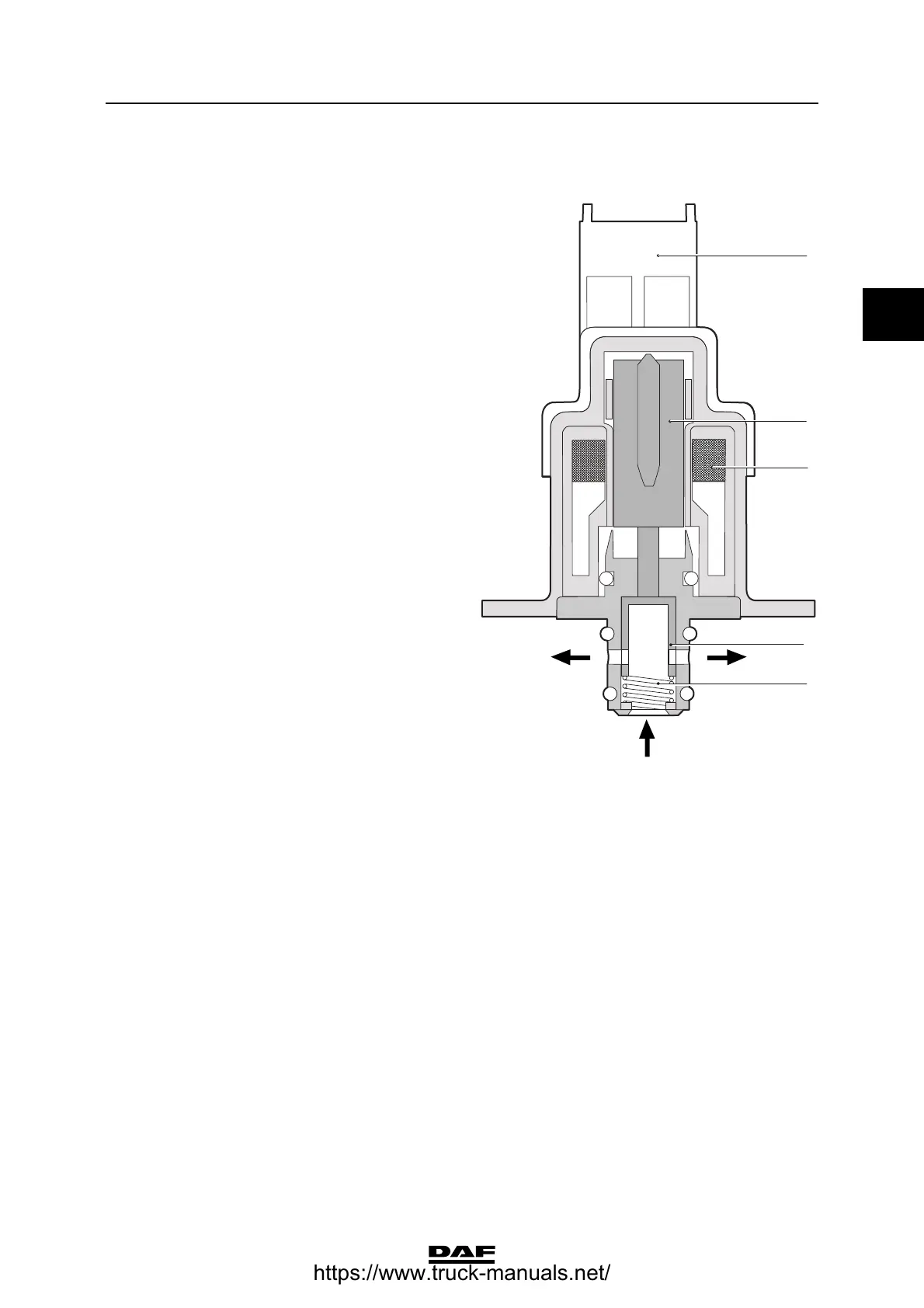

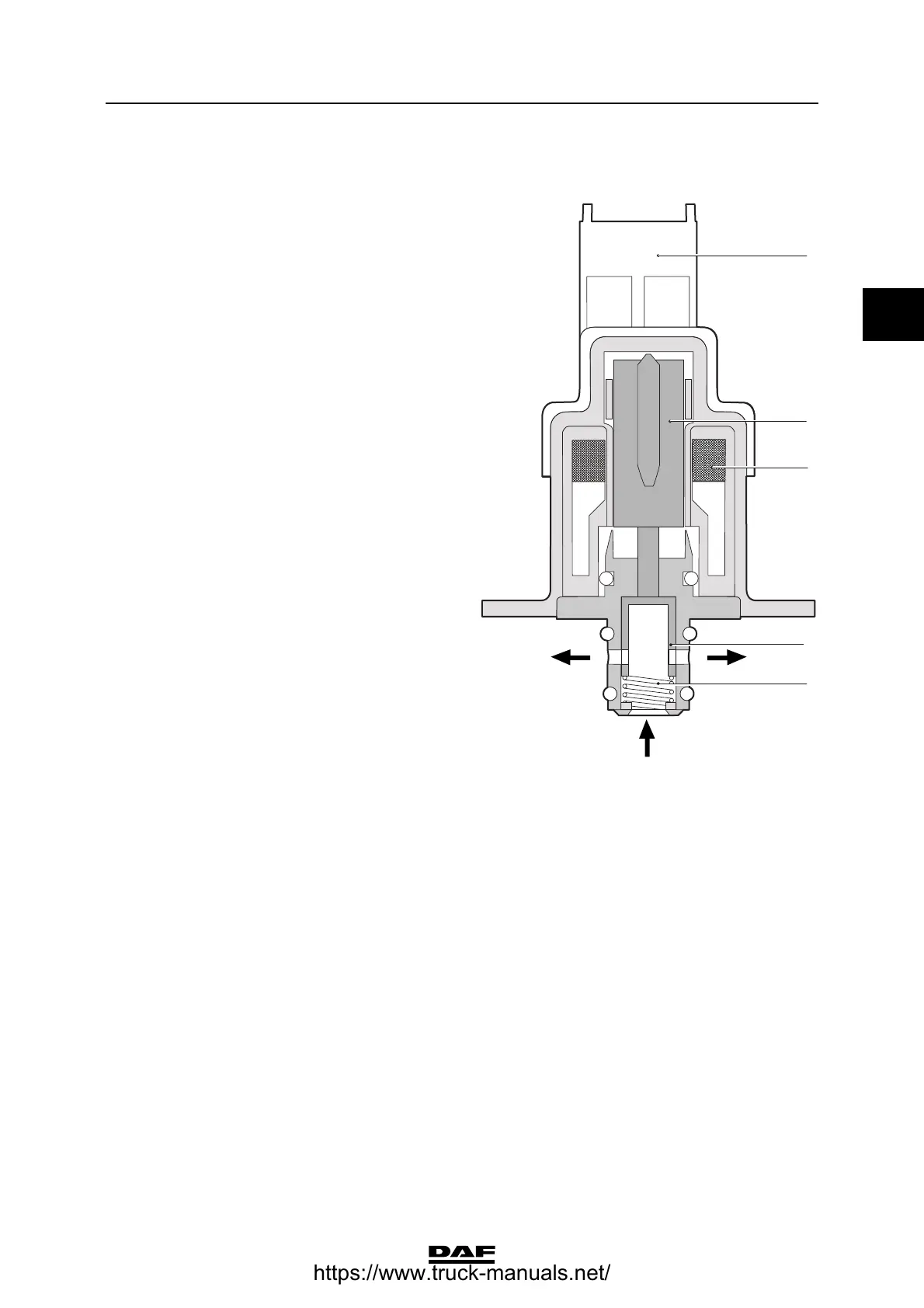

3.2 FUEL PUMP CONTROL SOLENOID VALVE

The high-pressure pump has an over-capacity for

normal operating conditions. This could lead to

large quantities of fuel being forced at high

pressure to the fuel rail and then directly being

drained out to the return pipe via the pressure-

limiting valve on the fuel rail. This produces too

much unnecessary heat and loss of capacity

because large amounts of fuel are flowing at high

pressure.

The system has been designed such that only

fuel that will be used will be forced under high

pressure to the rail. For this reason, a fuel pump

control solenoid valve has been fitted at the

suction side of the high-pressure pump. This

solenoid valve is opened without being

energised, so that the high-pressure pump

elements can be filled in the normal manner.

If the fuel rail pressure becomes too high, for

example because of lower fuel off-take on the rail,

the solenoid valve will be energised by the

electronic unit with a higher duty cycle, so that the

plunger is pressed with a greater force against

the spring pressure and the valve reveals a more

constricted opening. This reduces the fuel supply

to the pump elements and the pump output will

thus fall. The fuel rail pressure will also fall as a

consequence.

If the rail pressure is too low, the reverse is true.

The current is supplied to the coil (3) via the

connector (1). The current pushes the core (2)

with the plunger (4) against the pressure of the

spring (5). This controls the fuel current from

input A to output B.

Due to this valve, under normal circumstances

very little fuel flows back from the rail. This

improves performance and reduces the

generation of heat.

B

A

B

i400591

1

2

3

5

4

https://www.truck-manuals.net/

Loading...

Loading...