3.21.2 23-1* Maintenance

Wear and tear calls for periodic inspection and service of elements in the application, for example motor bearings, feedback

sensors and seals, or lters. With preventive maintenance the service intervals may be programmed into the frequency

converter. The frequency converter gives a message when maintenance is required. 20 preventive maintenance events can

be programmed into the frequency converter. Specify the following for each event:

•

Maintenance item (for example Motor Bearings).

•

Maintenance action (for example Replace).

•

Maintenance time base (for example Running Hours or a specic date and time).

•

Maintenance time interval or the date and time of next maintenance.

NOTICE

To disable a preventive maintenance event, set the associated parameter 23-12 Maintenance Time Base to [0] Disabled.

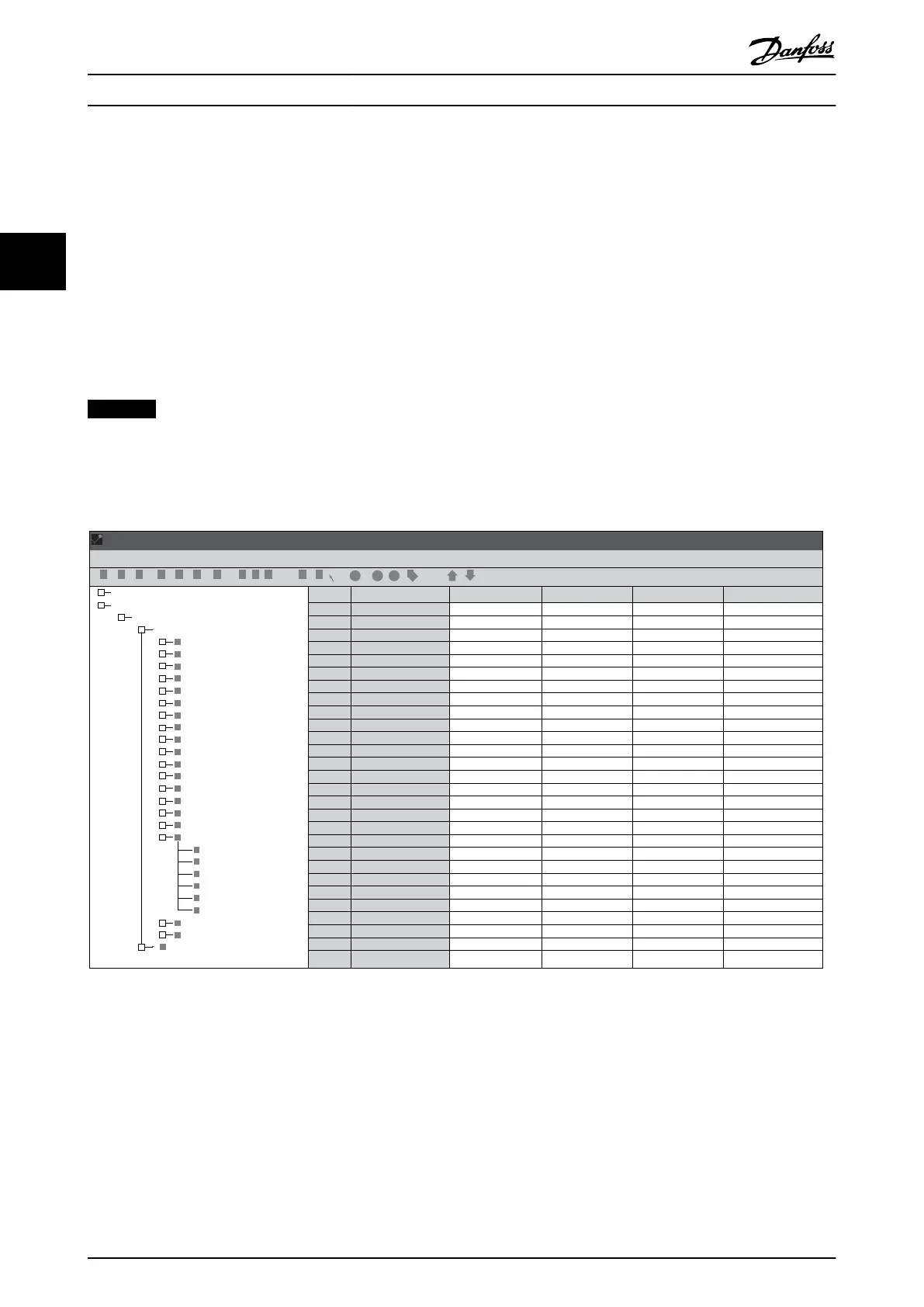

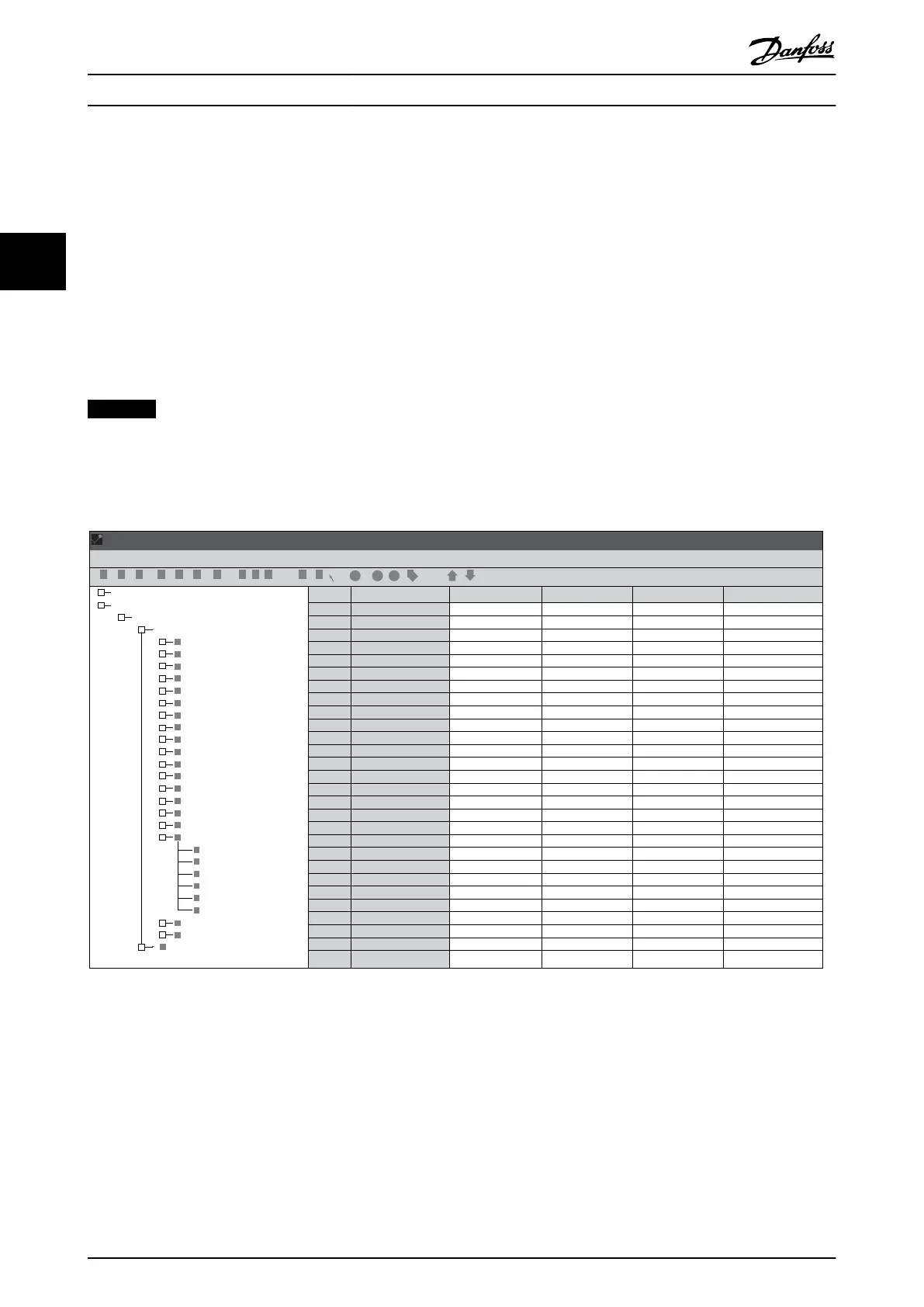

Preventive maintenance can be programmed from the LCP, but use of the PC-based VLT Motion Control Tool MCT 10 Set-up

Software is recommended.

+

-

+

-

-

-

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

130BA492.10

Untitled - MCT 10 SET - up Software

File Edit View Insert Communication Tools Options Help

ID Name Setup 1 Setup 2 Setup 3 Setup 4

2310.0 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.1 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.2 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.3 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.4 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.5 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.6 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.7 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.8 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.9 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.10 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.11 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.12 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.13 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.14 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.15 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.16 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.17 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.18 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2310.19 Maintenance Item Motor bearings Motor bearings Motor bearings Motor bearings

2311.0 Maintenance Action Lubricate Lubricate Lubricates Lubricate

2311.2 Maintenance Action Lubricate Lubricate Lubricates Lubricate

2311.3 Maintenance Action Lubricate Lubricate Lubricates Lubricate

2311.4 Maintenance Action Lubricate Lubricate Lubricates Lubricate

2311.5 Maintenance Action Lubricate Lubricate Lubricates Lubricate

2311.6 Maintenance Action Lubricate Lubricate Lubricates Lubricate

Network

Project

VLT AQUA DRIVE

All Parameters

Operation/Display

Load/Motor

Brakes

Reference / Ramps

Limits / Warnings

Digital In/Out

Analog In/Out

Comm. andOptions

Smart logic

Special Functions

Drive Information

Data Readouts

Info & Readouts

Drive Closed Loop

Ext. Closed Loop

Application Functions

Time-based Functions

Timed Actions

Maintenance

Maintenance Reset

Energy Log

Trending

Payback Counter

Cascade Controller

Water Application Functions

Cascade Controller

Illustration 3.61 MCT 10 Set-up Software

The LCP indicates (with a wrench icon and an “M”) when it is time for a preventive maintenance action, and can be

programmed to be indicated on a digital output in parameter group 5-3* Digital Outputs. The preventive maintenance status

may be read in parameter 16-96 Maintenance Word. A preventive maintenance indication can be reset from a digital input,

the FC bus, or manually from the LCP through parameter 23-15 Reset Maintenance Word.

A maintenance log with the latest 10 loggings can be read from parameter group 18-0* Maintenance Log and via the alarm

log key on the LCP after selecting maintenance log.

Parameter Descriptions

VLT

®

HVAC Drive FC 102

176 Danfoss A/S © 03/2015 All rights reserved. MG11CE02

33

Loading...

Loading...