e75ha208.10

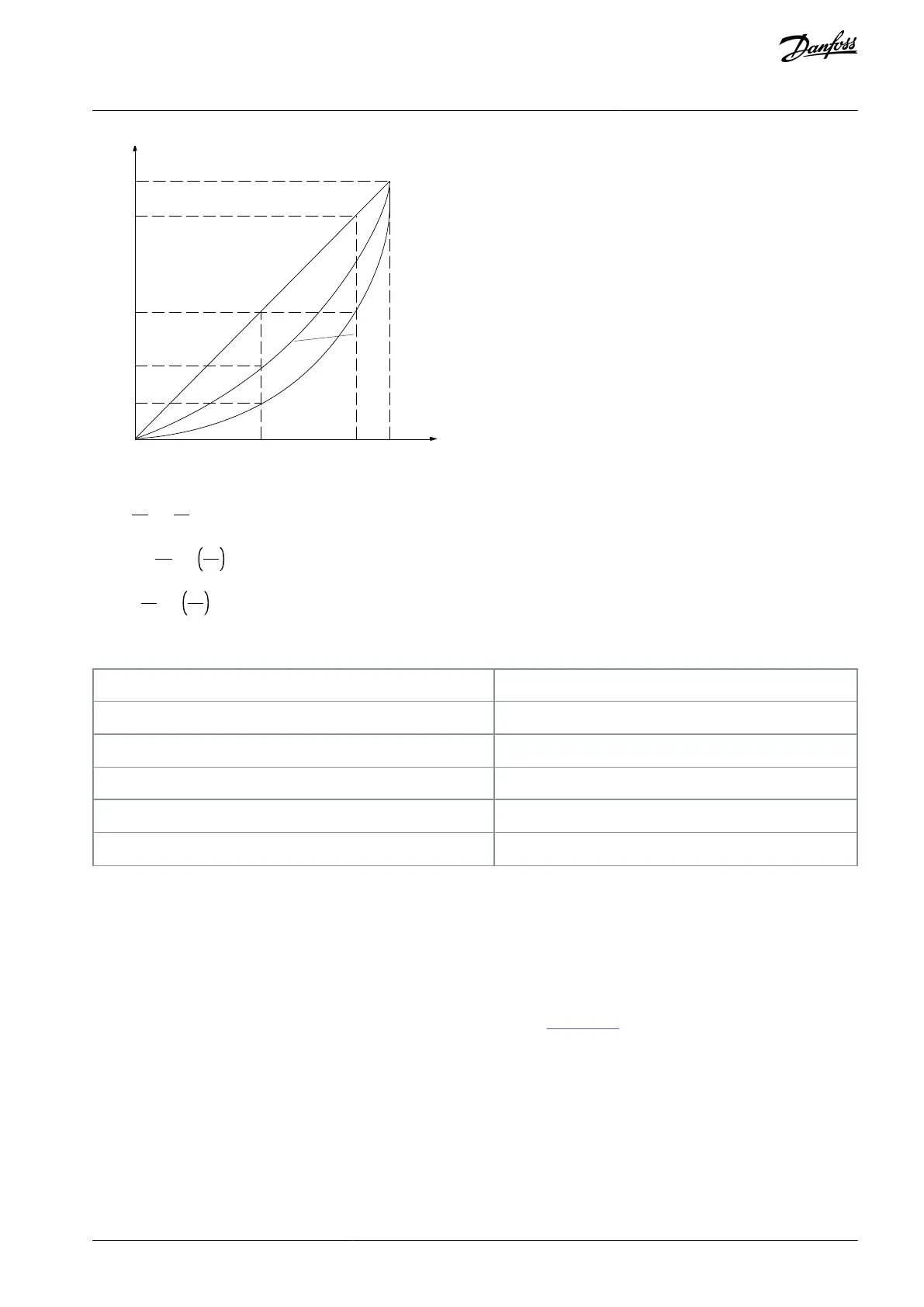

P o w er ~n

3

P r essur e ~n

2

Illustration 7: Anity Laws for Centrifugal Pumps

Flow:

Q1

Q2

=

n1

n2

Pressure:

H1

H2

=

n1

n2

2

Power:

P1

P2

=

n1

n2

3

Assuming an equal eciency in the speed range.

Anity Laws

Q

2

=Reduced ow (or increased ow)

P

2

=Reduced power (or increased power)

H

2

=Reduced pressure (or increased pressure)

n

2

=Reduced speed (or reduced speed)

4.3.2 Valve Control versus Speed Control of Centrifugal Pumps

Valve control

As the demand for process requirements in water systems varies, the ow to be adjusted accordingly. Frequently used methods for

ow adaptation are throttling or recycling using valves. A recycle valve that is opened too wide can cause the pump to run at the

end of the pump curve with a high ow rate at a low pump head. These conditions do not only cause a waste of energy due to the

high speed of the pump, but can also lead to pump cavitation resulting in pump damage.

Throttling the ow with a valve adds a pressure drop across the valve (HP-HS). This can be compared with accelerating and pulling

the brake at the same time in an attempt to reduce the car speed. As shown in Illustration 8, throttling makes the system curve turn

from point (2) on the pump curve to a point with signicantly reduced eciency (1).

AJ300847815559en-000101 / 130R0337 | 23Danfoss A/S © 2020.09

Product Family Overview

VLT® AQUA Drive FC 202

Design Guide

Loading...

Loading...