•

•

•

The eciency classes IE0 to IE2 of the drive controller as specied in IEC 61800-9-2 (EN 50598-2) refer to the 90/100 operating point,

i.e. 90 % motor stator frequency and 100% torque current (see Illustration 15).

Relative torque

producing current

Relative

motor stator

frequency

100 %

50 %

25 %

0 %

0 % 50 % 90 %

e30bu373.10

Illustration 15: Operating Point according to IEC 61800-9-2 (EN 50598)

Since in the future all component manufacturers will disclose their loss data according to this new standard, optimized applications

can be designed with a wide range of dierent components. The new Standard allows an accurate preliminary calculation of the

power losses, so that the ROI (Return of Investment) can be reliably determined. Up to now the overall eciency of speed-regulated

electric motors was estimated with the aid of approximate energy consumption calculations.

It is now possible to determine the total losses of a system for the 8 operating points dened in the standard, including the part load

operation, via a simple addition of power losses. Danfoss helps its customers to avoid having to rely on system solution providers, to

ensure that their systems will retain a competitive advantage also in the future.

EC 61800-9-2 (EN 50598-2) shifts the focus from the individual component to the eciency of the whole drive system. The new

eciency classes (International Eciency for Systems, IES)

allow a simple determination of the total losses for a whole drive system (PDS).

Danfoss oers the MyDrive

®

ecoSmart

™

tool, which is available online or as a Smartphone app to assist with the eciency calcula-

tion. Use MyDrive

®

ecoSmart

™

to:

Look up part load data as dened in IEC 61800-9-2, for VLT® and VACON® drives

Calculate eciency class and part load eciency for drives and power drive systems

Create a report documenting part load loss data and IE or IES eciency class.

For more information, refer to

http://ecosmart.danfoss.com.

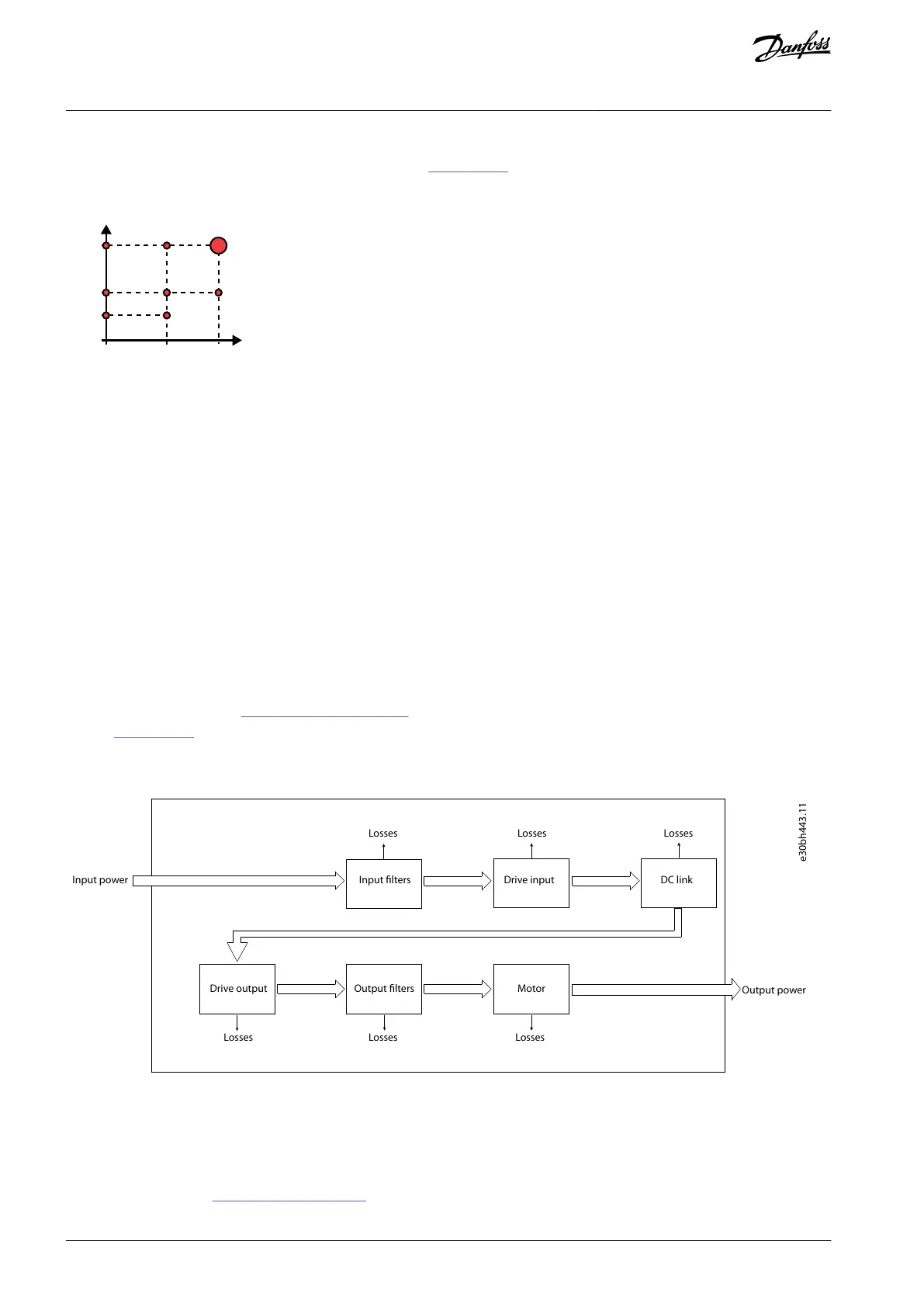

Refer to Illustration 16 to see the components in the PDS which contribute to losses in the design. Mains cables and the load ma-

chine are not a part of the PDS, even though their losses can be signicant and could be a part of the evaluation of the overall

energy eciency of the installation.

Illustration 16: Losses in a Power Drive System

4.5 Software Tools

Danfoss oers a suite of software tools which have been designed to provide easy operation and the highest level of customization

of AC drives.

The tools are available at suite.mydrive.danfoss.com.

AJ300847815559en-000101 / 130R033728 | Danfoss A/S © 2020.09

Product Family Overview

VLT® AQUA Drive FC 202

Design Guide

Loading...

Loading...