FC 300 Design Guide

Introduction to FC 300

Optimization of the process regulator

The basic settings have now been made; all that needs to be d one is to optimize the proportional

gain, the integration time, and the differentiation time (par. 7-33, 7-34, 7-35). In most

processes, this can be done by following the guidelines given below.

1. Start the motor

2. Set par. 7-33 (Proportional Gain) to 0.3 and increase it until the feedback signal again

begins to vary continuously. Then reduce the value until the feedback signal has

stabilized. Now lower the proportional gain by 40-60%.

3. Set par. 7-34 (Integral Time) to 20 sec. and reduce the value until the feedback signal

again begins to vary continuously. Increase the inte gration time until the feedback

signal stabilize s, followed by an increase o f 15-50%.

4. Only use par. 7 -35 for very fast-acting systems (differentiation time). The typical value is f

our times

the set integral time. The differentiator should only be used when the setting of the proportional

gain and the integral time has been fully optimized. Make sure that oscillations in the feedback

signal are sufficiently damped by the low-pass filter on the feedback signal.

NOTE

If necessary, start/s top can be activated a number of times in order to provoke

a variation of the feedback signal.

" Ziegler Nichols Tuning Method

In order to tune the PID controls of the adjustable frequency drive, several tuning methods

can be used. One approach is to use a technique which was developed in the 1950s but which

has stood the test of time and is still use d today. This meth

od is known as the Ziegler Nichols

tuning method and it can be considered "quick and dirty."

NOTE

The method described must not be used on applications that could be damaged by the

oscillations created by marginally stable con

trol settings.

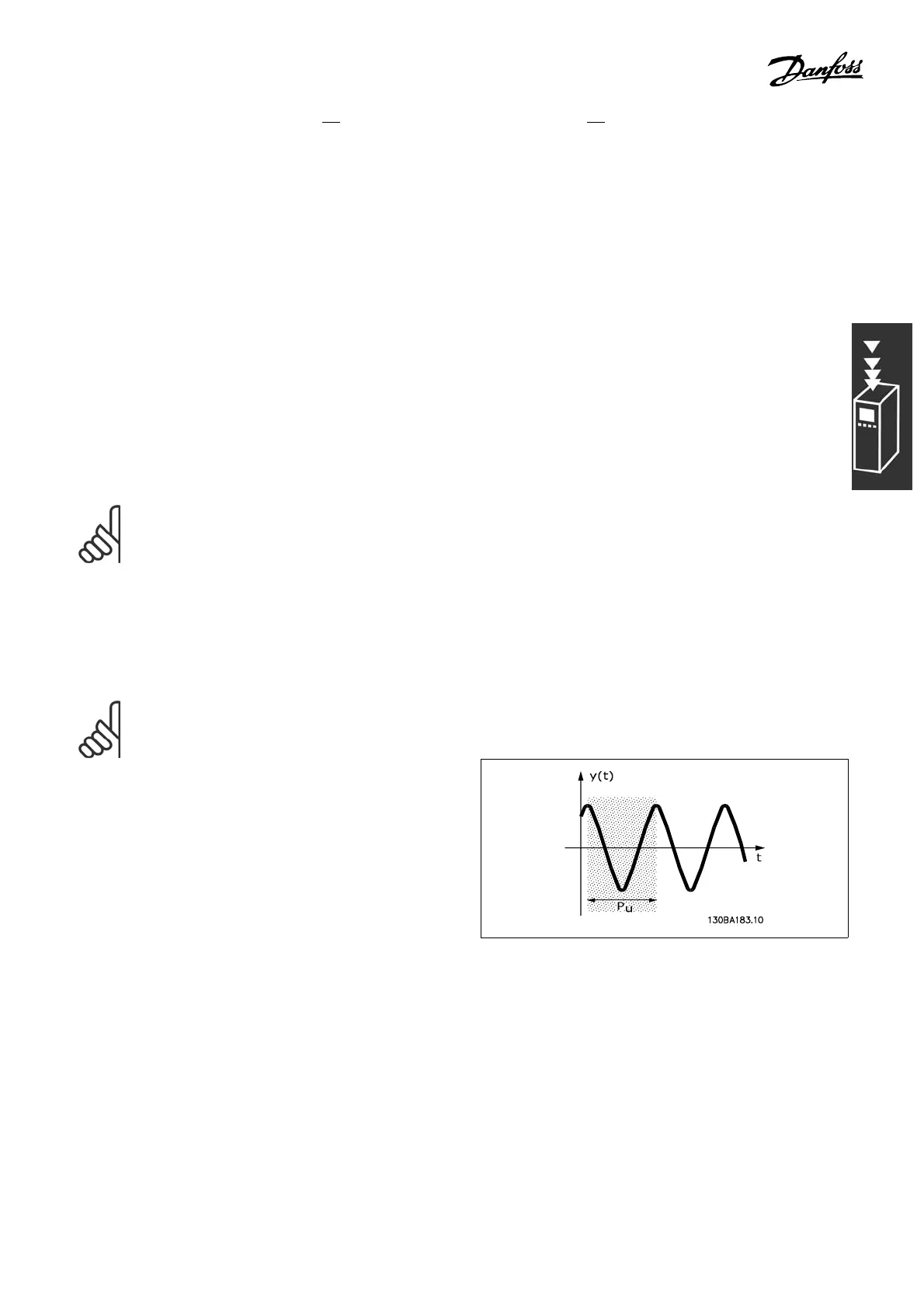

The criteria for adjusting the parameters ar

ebased

on evaluating the system at the limit of stability

rather than on taking a step response. We increase

the proportional gain until we observ

e continuous

oscillations (as measured on the fe edb ack), that is,

until the system becomes marginally stable. The

corresponding gain (called the ul

timate gain) and

the period of oscil lation (also called the ultim ate

period) are determined as shown in Figure 1.

Figure 1: Marginally stable syste m

P

u

should be measured when the amplitude of oscillation is quite small. Then we "back

off " from this gain again, as shown in Table 1.

41

MG.33.B3.22 - VLT is a registered Danfoss trademark

Loading...

Loading...